Supply User Manual ENG -> 5. Warehouse -> 5.12 LU-SU4205 Replenishment Rules -> A. LU INTRODUCTION (LU-SU4205)

A. LU INTRODUCTION (LU-SU4205)

Replenishment Rules are there to avoid stock shortages, and to facilitate supply planning when it is time to reorder products.

RR (Replenishment rules) is a functionality supporting an ordering mechanism. From operational point of view RR enables to oversee forecasting stock levels, calculation of orders, analyzing and ordering of stock in order to prevent ruptures in the strategic planning. Replenishment rules provide a proposal of products and quantities to order considering the defined configuration of inventories specific to the product/mission.

For this, an accurate visibility of the current situation of quantities in stocks, quantities which will expire and quantities in the pipeline is necessary as well as their consumption. For RR any calculation in terms of proposing quantities is always done on the forecasted as the system never propose the quantity based on historical consumption only.

As you may have noticed by the definition, this feature presents a relatively high level of complexity and is therefore dedicated to users with advanced knowledge and subject to user rights (see with your OC processes).

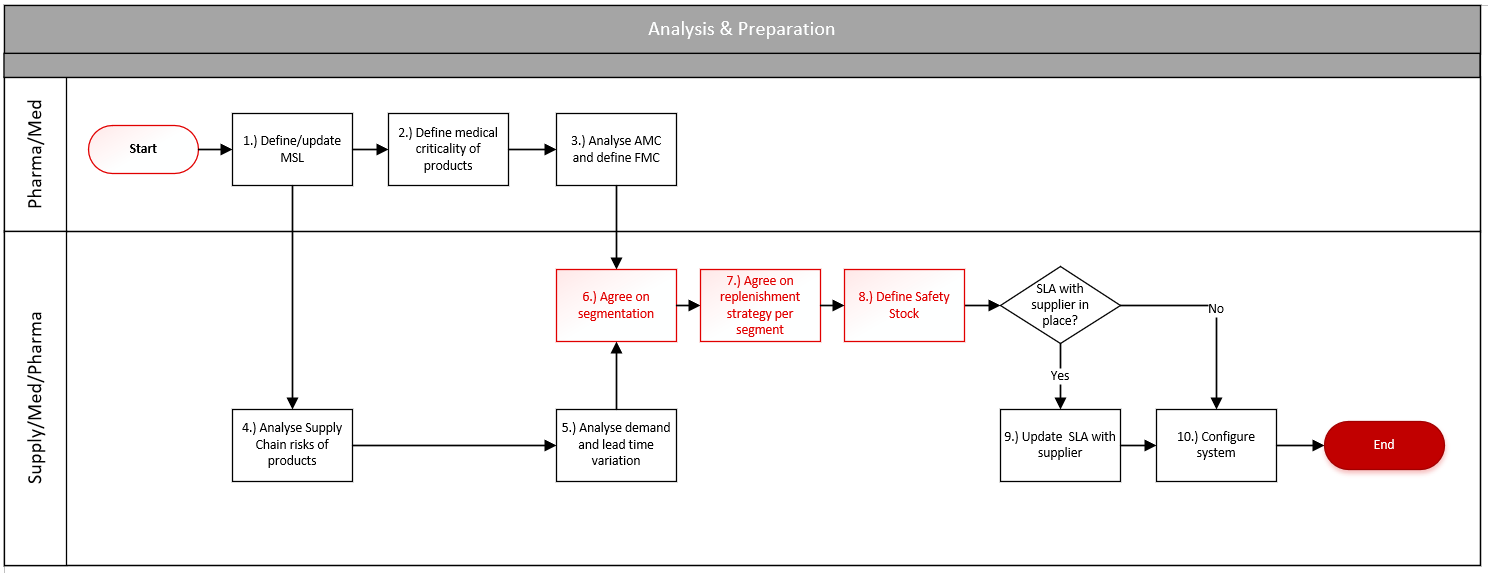

Analysis and Preparation process flow:

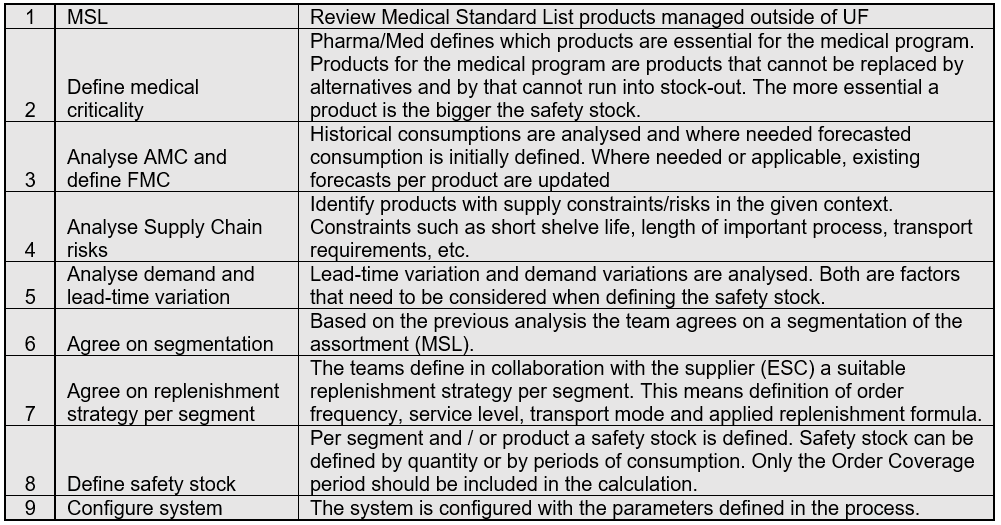

Below table represents the operational scope of processes which are considered for per-analyse which stay outside of Unifield system. It does not define the operational steps to be done in Unifield. Table provides more complex entire view about the processes and whole operational cycles. However, there are some parts in the table which are also available in Unifield system, e.g. definition of FMC. The final stage is config in Unifield with some of the elements depicted in the table at the bottom.

Processes to configure RR (detailed steps elaborated below) in the system is to first define and configure your “Location Config” (choosing a location for own instance or across multiple instances) ; second step is the creation of “Parent Segment” and third step is configuration of “Replenishment Segment” with list of products. For report purposes “Inventory Review Config” and “Product List Consistency Report” are used.