Supply User Manual ENG -> Products -> 3.2 LU-SU2101: General Product Management -> L. How to merge a UniField local product with a UniData product (Coordination only)

L. How to merge a UniField local product with a UniData product (COOrdination only)

Creation of local product is moving from a UF scope to a UD management scope. In order to smooth this transition, the “Merge” feature has been developed. The main goal is to eventually replace all the UF products with “Product Creator” = “Local” to UD product (“Product Creator” = “UniData“).

The process of migration of Local products is outlined by UniData/Spinco documents, and is to be managed, and overseen by each OC’s HQ level in consultation with UniData. The merging of products is a tool in this larger process and therefore its scope is to be used in line with agreed protocols, and only following a clear decision, with full recognition of the outcome.

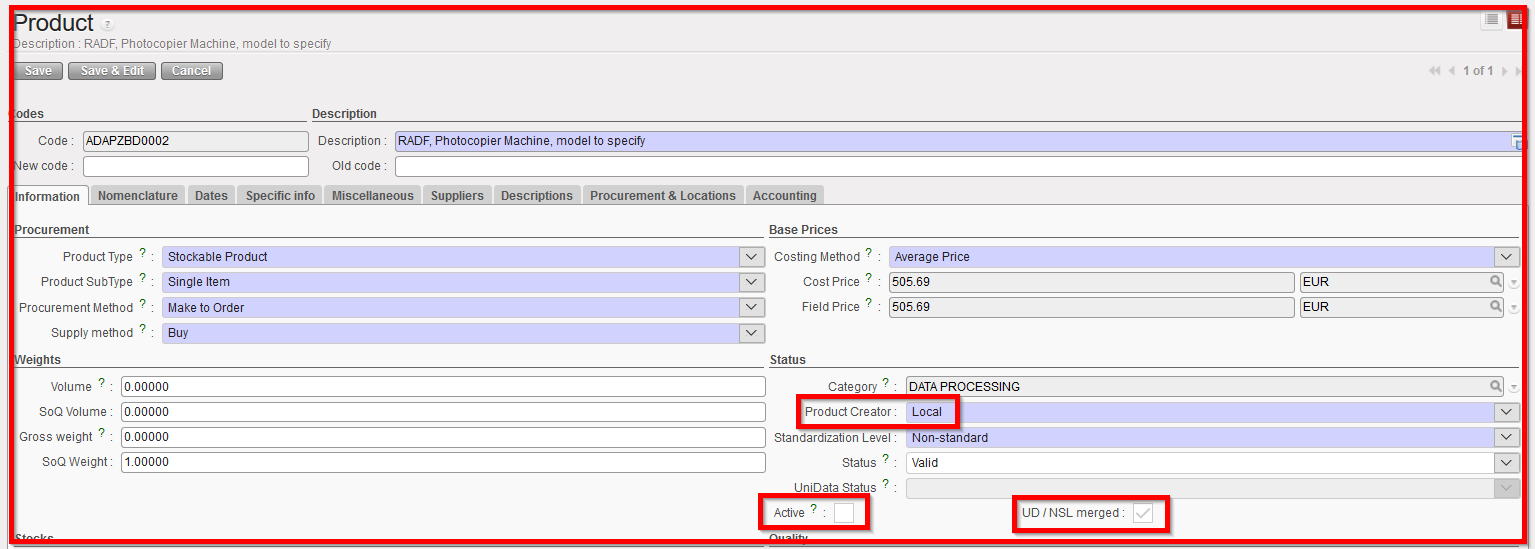

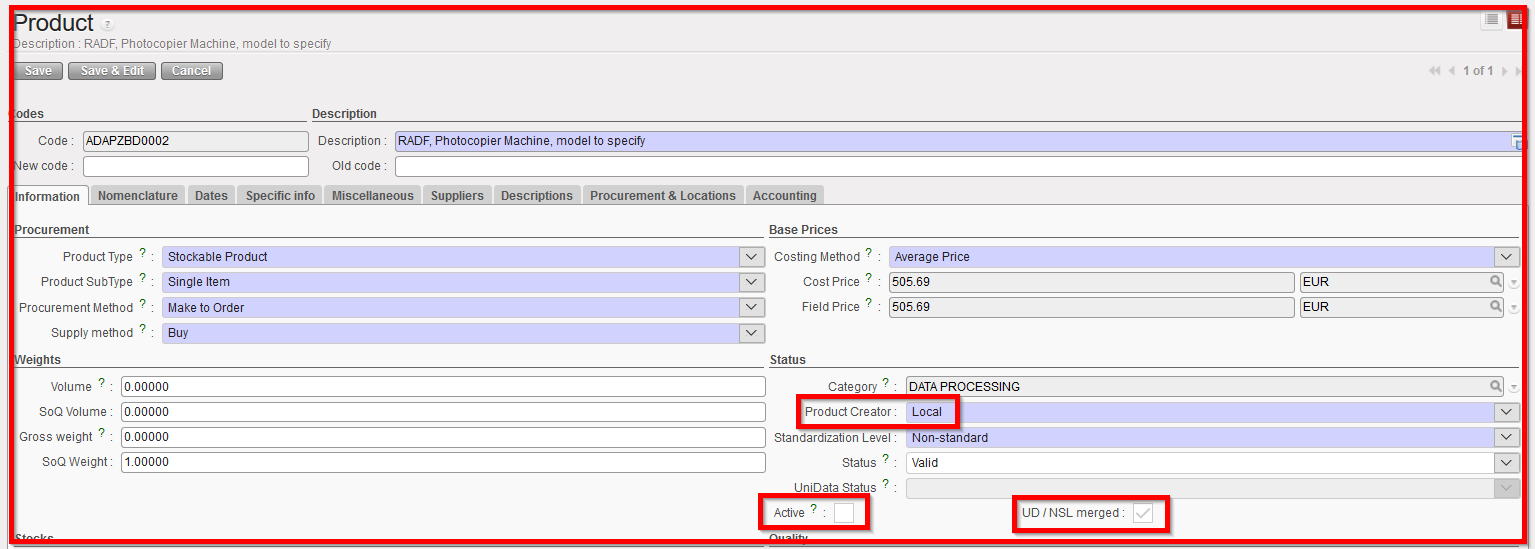

The merge is intended to be done on a one to one basis and only from Coordination instance. Therefore, the button “Merge product” will be found on the local UF product only and can only be merged to one UD product. It will be a one shot action meaning that once merged the local product cannot be un-merged and will be deactivated for good (its only reference will remain in the “old code” field from the related UD merged product and obviously in the “Track changes”) while the new merged UD product will be active.

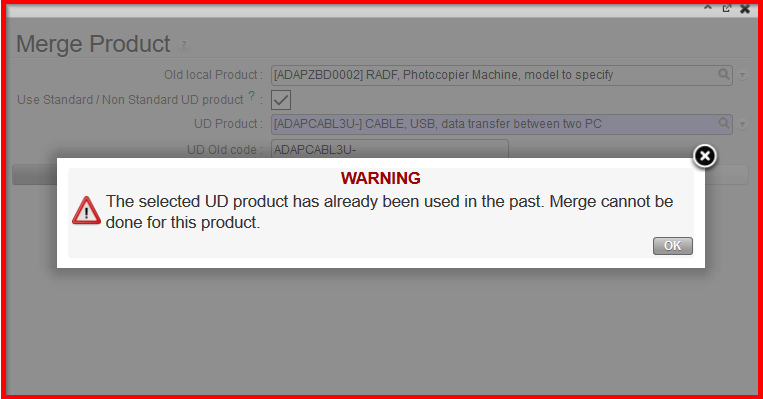

The new merged UD product can also be merged only once and should have no history.

Any merge done at Coordo level will automatically be pushed to project level after next synchronization, and products in lower instance level should be merged in the same way.

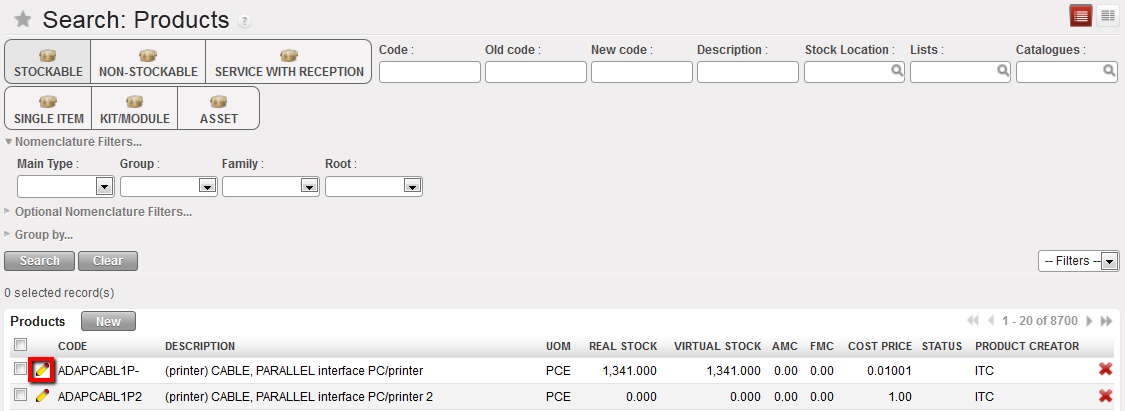

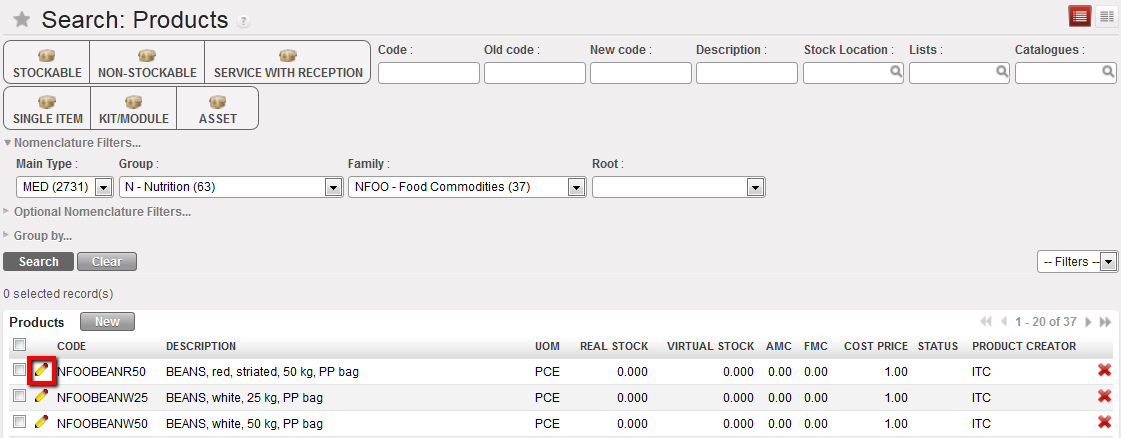

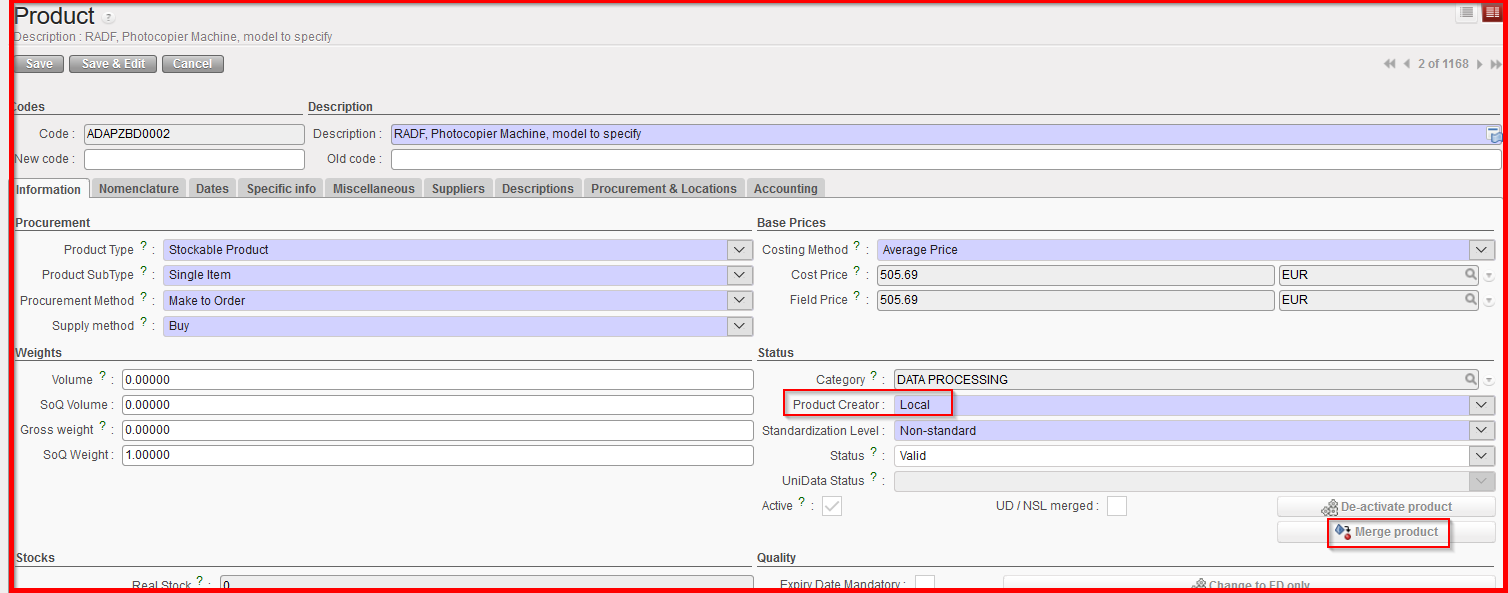

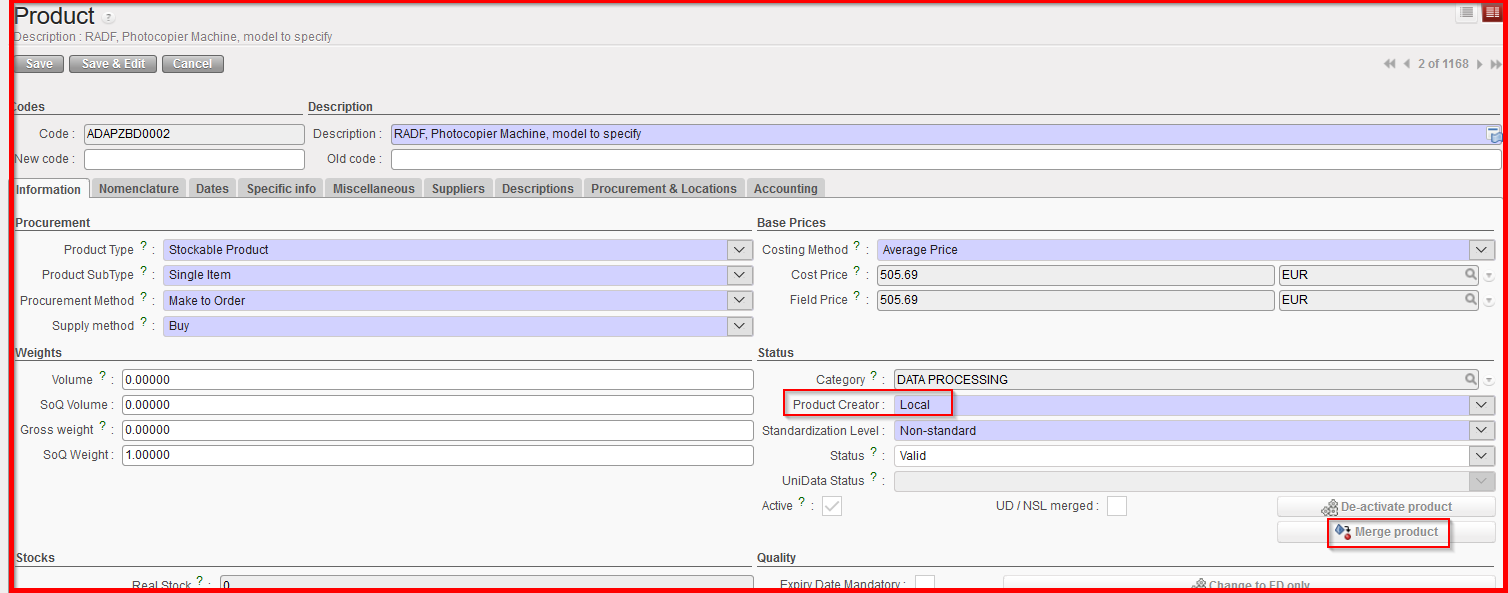

To merge a UF local product, go to: Products/ Products

- Use the search tools to filter values to find the product you want to edit (it has to be a product with “Product Creator” = “Local”)

- Click on the product line to open it

- Click on the “Merge product” button

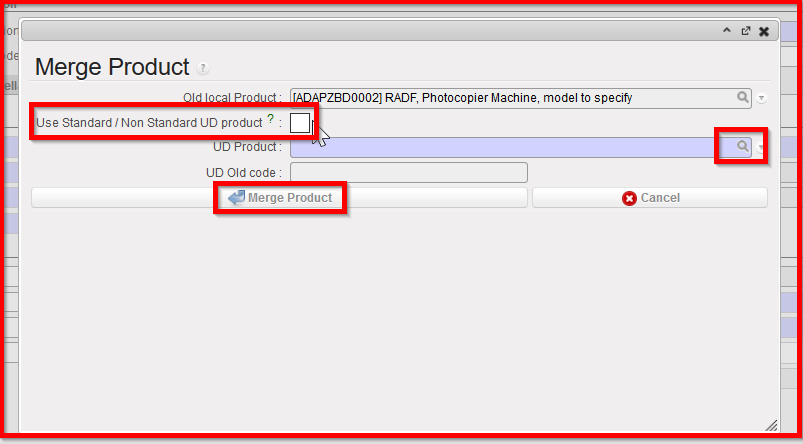

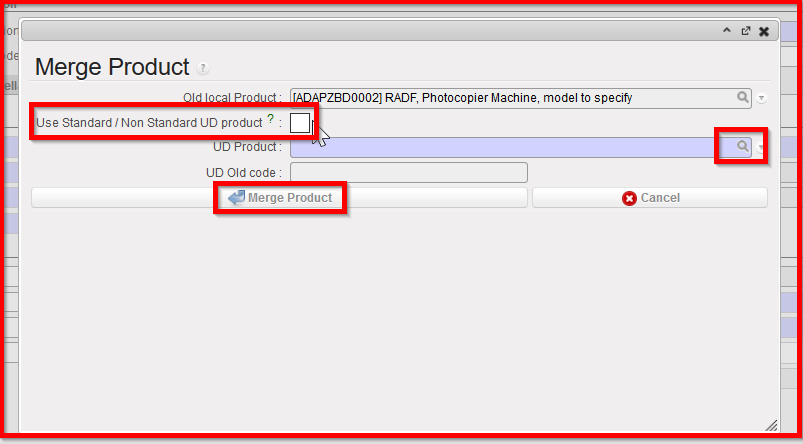

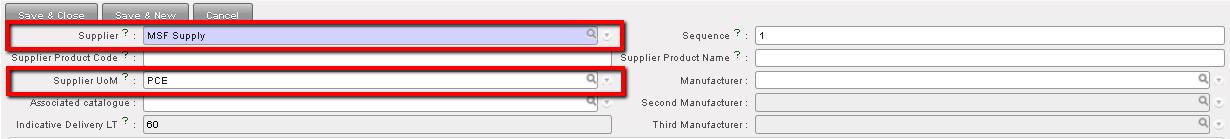

4. From the wizard, select the UD product to be merged by clicking the magnifier from the “UD product” field

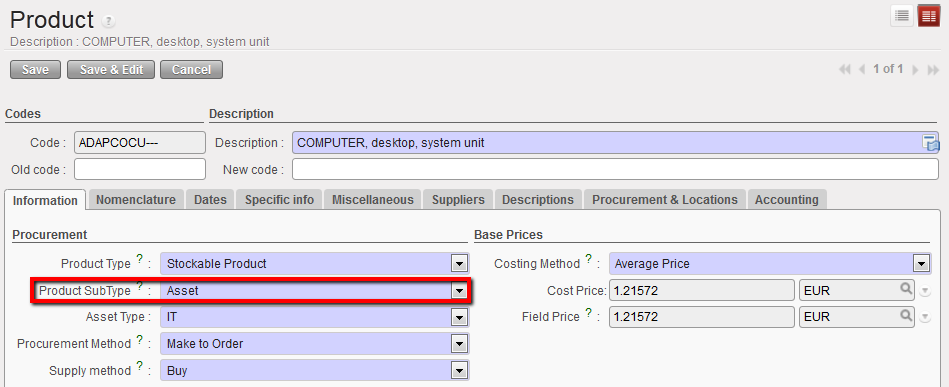

a) By default, only NSL products can be selected to be merged

b) To be able to select a Standard or Non-Standard UniData product to merge, the checkbox “Use Standard/ Non-Standard UD product” must be ticked (only products which are Active).

5. Click on “Merge Product” on the wizard

The UF local product is now Inactive and cannot be reactivated. It is also now ticked as “UD/NSL merged”.

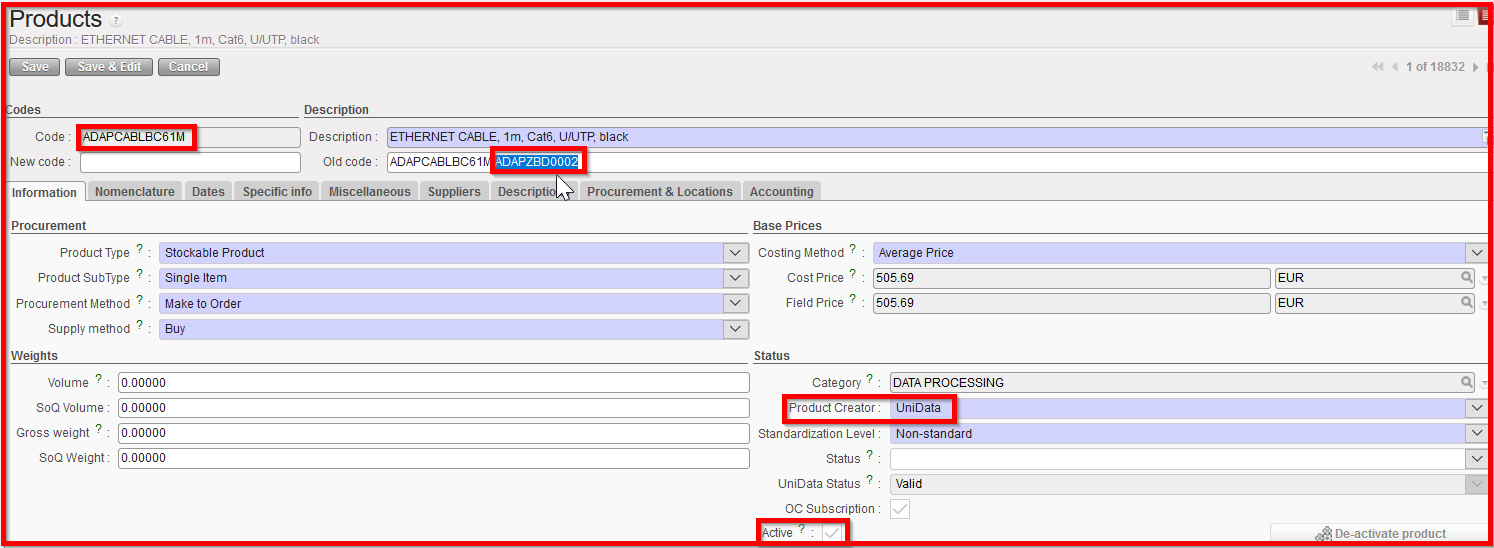

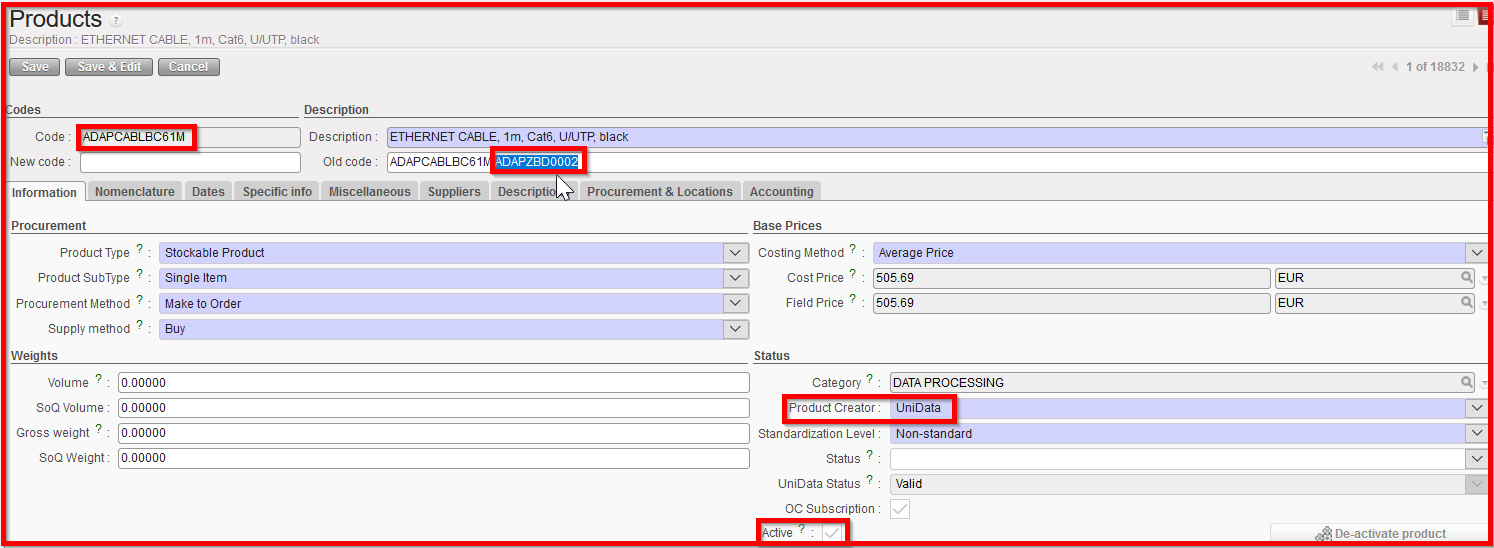

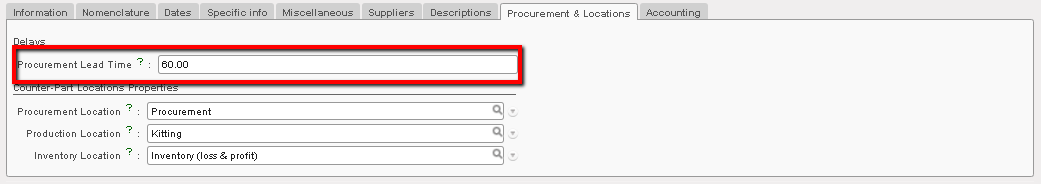

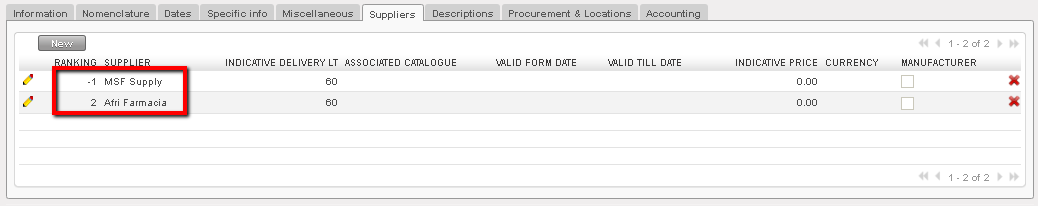

The new UD merged product has now replaced this UF local product an all existing open or closed document and has the UF local product referenced in the “Old code” field:

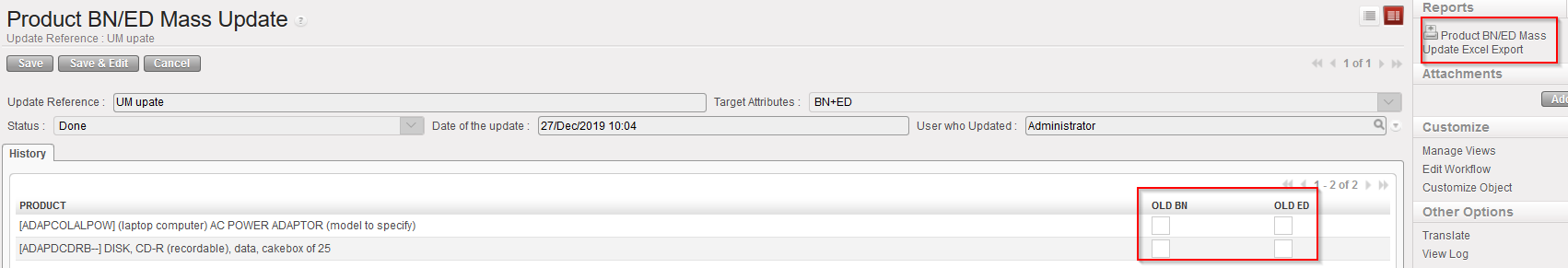

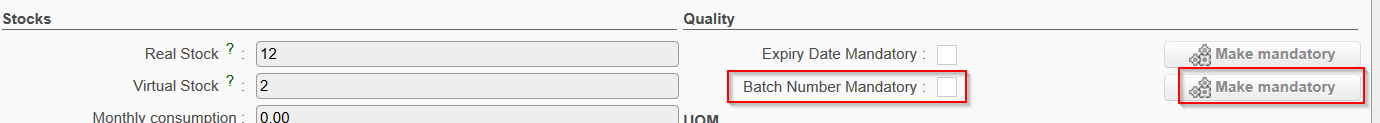

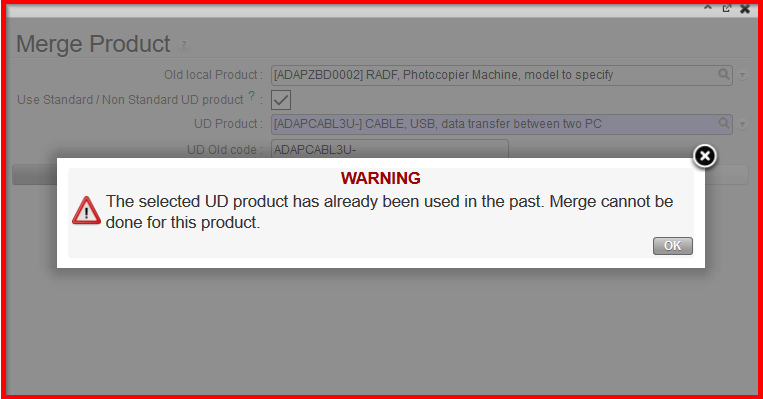

Please note that after clicking on “Merge Products” from the wizard, some checks are done on the products history, presence in Stock mission report and some attributes (i.e: BN/ED) then a blocking explicit message can prevent the merge when necessary. In case of blocking message related to attributes, user can still update the UF product so that merge can be done.

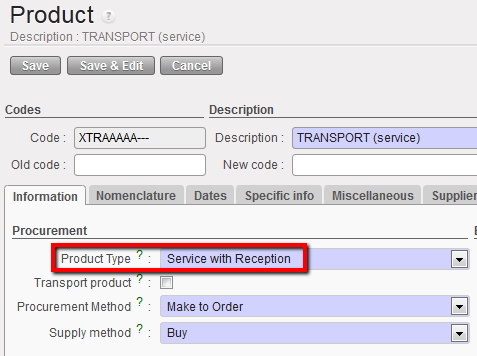

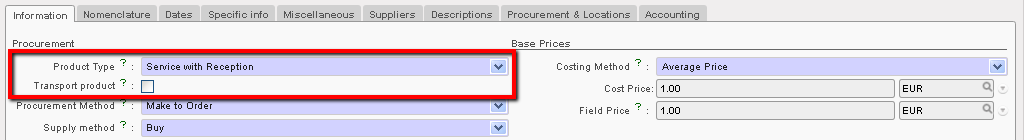

Note that there can also be non-blocking message for attributes and that UD products attributes will prevail in case of discrepancies ( “Nomenclature” or “Temperature sensitive” or “Product type”).

next to the list to open it in edit mode

next to the list to open it in edit mode

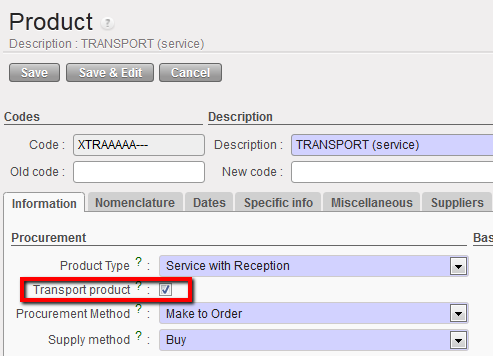

Please note: The UoM in the purchase order service with reception can be percentage (100%) as this will facilitate payment in installments for a service if this was the payment term agreed with the supplier.

Please note: The UoM in the purchase order service with reception can be percentage (100%) as this will facilitate payment in installments for a service if this was the payment term agreed with the supplier.