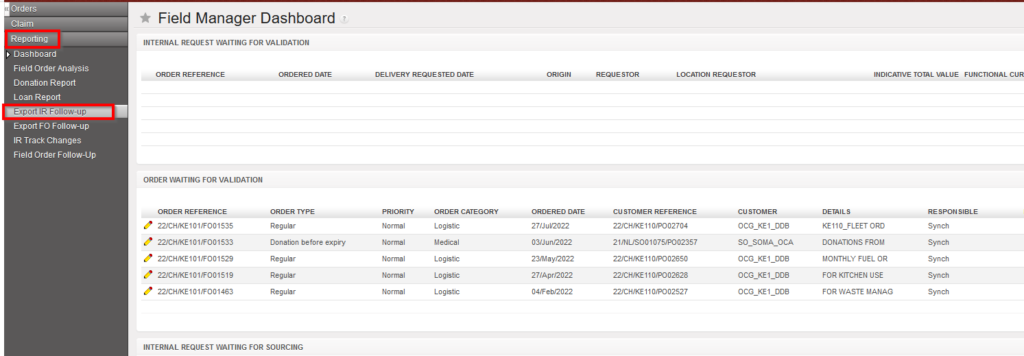

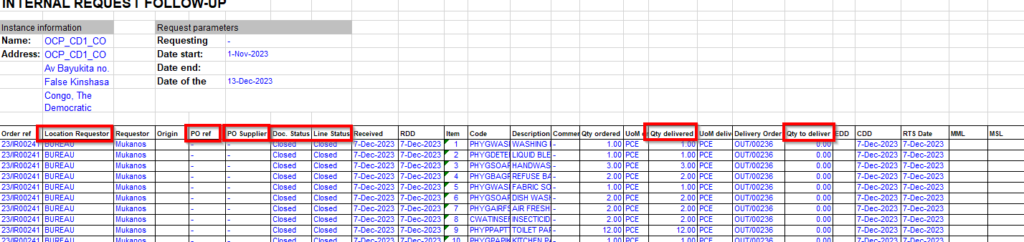

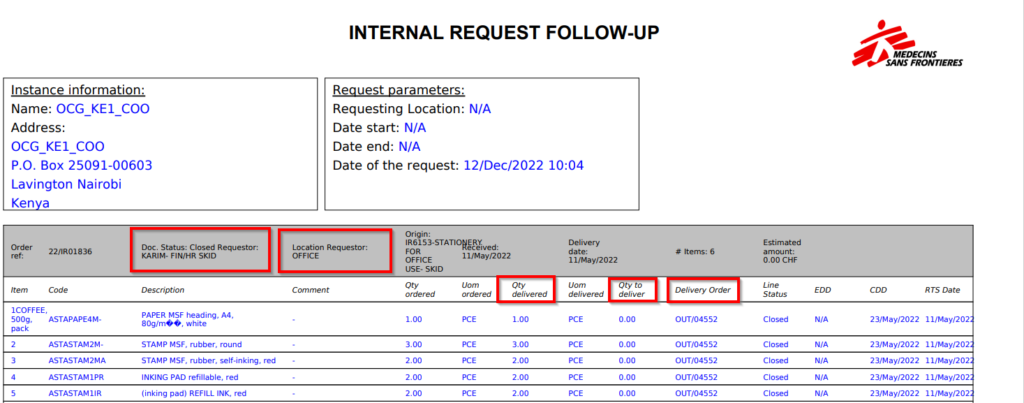

Supply User Manual ENG -> 4. Procurement -> 4.3 LU-SU3102: Orders Sourcing Tool (OST) -> A. LU Introduction (LU-SU3102)

A. LU Introduction (LU-SU3102)

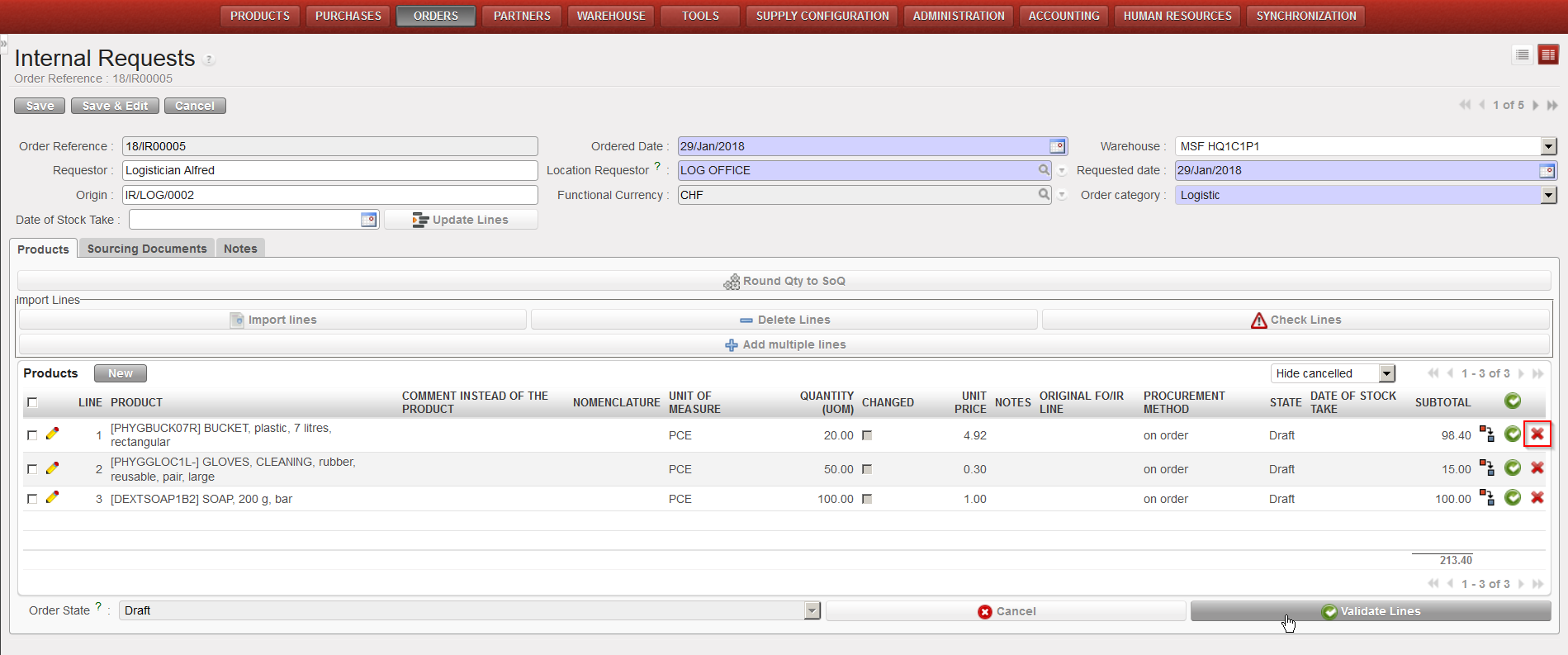

The sourcing process is the process of selecting the source from which the requested goods will be taken (from stock or through a purchase). The orders Sourcing tool (OST) allows the sourcing of all validated requirements (order lines of Internal Requests and Field Orders). In the OST, you are able to source IR-lines and FO-lines which are in the state “Validated“. The OST displays the requests (product, quantity, RDD date), the stock levels (real stock, available stock and virtual stock) and if appropriate, the supplier information (default supplier if defined in the PMD sheet, estimated delivery date,…).

Some products may be active in more than one catalogue, in the supplier pop-up that opens after clicking the magnifying glass, system will display the suppliers with active catalogues in Green at the top of the list.

A Field Order (FO) is a document expressing a request from an internal partner. Field Orders are explained in detail in LU-SU3103 and LU-SU3104. As the sourcing mechanism of IRs and FOs is very similar, you will notice that FOs are already introduced in this learning unit.

Only the “Validated” order lines of a document (IR or FO) will be possible to source through the OST. As we will see later, lines of requests which are created following a cancel & resource process will have the state “Resourced-v“. However, these lines will also appear in the OST and be available for sourcing because the OST will consider them as “Validated“.

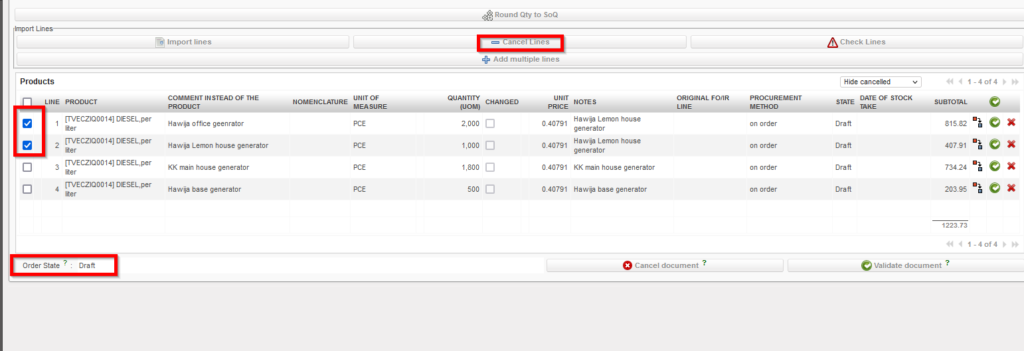

If the sourcing is done “on order“, after sourcing, the associated documents (Purchase Orders, Direct Purchase Orders, Tenders or Requests for Quotation) will be created automatically by the system in “Draft” status while the sourced IR/FO-lines will switch to the state “Sourced“.

If the sourcing is done “from stock“, after sourcing, the associated documents (delivery orders in case of IR with an external location as destination location, internal moves in case of IR with an internal location as destination location or picking tickets in case of FO) will be created automatically by the system in “Confirmed” status (delivery orders and internal moves) or “Draft” status (picking tickets) while IR/FO-lines will switch to the state “Confirmed“

If the sourcing is done “on order” and to a PO, the system will group by default all order lines into POs based on the selected supplier and the requested delivery date (RDD). It means that order lines sourced to the same supplier with the same requested delivery date from different IRs and FOs will be grouped into the same PO. These default settings can be changed at the supplier level so that POs can be gathered by project, category or order reference.

Sourcing groups can also be defined in the supply configuration of UniField (see column “Group” in the OST) to decide with greater precision how order lines will be gathered/split on POs. These optional settings will be explained later in details (LU_SU3401 Procurement advanced feature H.How to source on order (IR or FO) on several Pos for the same ESC (and same RDD)).

Once all lines of a document have been sourced and processed, the system will automatically close the document.

Process Flow of Sourcing (Orders Sourcing Tool)

Example of flow through sub-menus if sourcing a single line IR to a PO to external supplier.

Go to: Orders / Orders / Orders Sourcing Tool

In the Orders Sourcing Tool screen, the filter buttons/search fields of the sourcing tool which are located at the top of the screen allow the user to display only the lines to be sourced.

|

| OST filters |

By default validated IR/FO-lines appear in the OST with the most relevant information such as requested products, requested quantities, proposed sourcing method and stock levels.

It is possible to sort the lines by clicking on the column header, for example, clicking on the RDD, System will re-arrange the lines according to their “Requested Delivery Dates”.

When one line is selected, all last POs that contain this product can be viewed Via “Purchases” in the “Action Menu” under “Links”

The column “Location” of the OST is used to select any internal location from which sourcing from stock can take place (intermediate stock, internal consumption unit, LOG/MED,…). If you change the proposed location, the real, available and virtual stock quantities are updated to reflect the quantities present in the selected location.

Note that for this ”Location” field , the “Stock” location cannot be selected if its child location MED/LOG have been chosen as “Location requestor” in the IR and vice versa.

|

| Orders Sourcing Tool |

The “Comment” column is mostly helpful as it displays a comment for product lines without code, “products by nomenclature“. This “Comment” column is also populated with comments entered at IR or FO line level on product lines correctly codified. Note that product lines with “products by nomenclatures” can only be sourced “on order”.

On the IR-lines to source the “Comment instead of the product” will appear in this column. Note that “Notes” which may have been entered at IR-line level are not appearing in the OST.

On the FO-lines to source, the “Comment” which may have been entered at FO-line level will also appear in the OST. The “Notes” entered on the FO-line won’t appear in the OST.

|

| Comment field used for “products by nomenclature” |

In case you do not have sufficient quantities in stock and would like to source the missing quantities “on order” via procurement, you can use the “Split line” icon  which allows you to split the quantities between the available/missing quantities. You will then be able to source the different lines of the same item using appropriate sourcing options.

which allows you to split the quantities between the available/missing quantities. You will then be able to source the different lines of the same item using appropriate sourcing options.

|

| Sourcing tool, splitting a line, step 1 |

|

| Sourcing tool, splitting a line, step 2 |

|

| Sourcing tool, splitting a line, result |

The “Source lines” link in the action menu on the right of the OST screen allows sourcing several lines in one step and changing the sourcing method of several lines in one step.

|

| OST action menu – Source lines |

|

| Selecting the sourcing location for multiple order lines sourced from stock |

By default, the option “Auto POs creation“, available in the action menu of the OST, (which triggers the creation of Purchase Order, RFQ or Tender documents according to the sourcing method selected) does not need to be manually actioned anymore as the default settings of UniField will launch automatically the “Auto POs creation” as soon as a line is sourced on order.

Nevertheless, these settings (available in the supply configuration) can be changed. In this case, these documents will only be created when user launches the “Auto POs creation“.

|

| OST action menu – Auto POs creation |

![]() on the right side of the line to save your changes.

on the right side of the line to save your changes.![]() on the right line side.

on the right line side.