Supply User Manual ENG -> 5. Warehouse -> 5.1 CHAPTER OVERVIEW: DELIVERIES, STOCK MANAGEMENT AND REPORTING.

Deliveries, Stock Management and Reporting.

This chapter covers all the necessary functionalities related to warehousing. It is divided in three parts: deliveries (inbound and outbound), stock management and reporting.

The deliveries part deals with the reception (IN) and the delivery (OUT) of products in UniField. This includes receiving partial deliveries, receiving alternative goods, processing goods with expiry dates and batch numbers, picking products, packing products, processing outgoing shipments, … The system offers a wide range of functionalities to process these types of warehouse related operations.

The stock management part explains all the necessary functionalities needed to manage a warehouse with UniField. This includes moving goods from a location to another, addressing a claim to a supplier, recording the consumption of products, managing kits, creating inventories, …

The reporting part focuses on reports which are available in UniField to allow traceability, consumption analysis and stock analysis.

Receptions and deliveries are actually movements from one location to another. As we will see, many transactions used in warehouse management trigger the creation of a movement. A movement always has a source location and a destination location.

Stock management in UniField can be compared to a double-entry system in accounting. The stock levels (or stock quantities) do not appear and vanish magically within the warehouse, they are just moved from one location to another and, just like accounting, the double-entry system offers a big advantage for tracing missing stock or inaccurate counts, as you can trace a product’s movements and search for source and destination locations.

In UniField, the inventory management of stocks is based on a hierarchical locations structure, from warehouse to intermediate stocks and consumption units (depending on the warehouse set up). UniField has the capacity to manage batch numbers and expiry dates so as to ensure compliance with the traceability requirements.

The warehouse is designed to reflect physical and non-physical locations from which you can deliver products to the customers and into which you can receive products from suppliers. Furthermore, as stock locations are hierarchically organized, you can carry out analysis at various levels of detail.

UniField also introduces the concepts of “virtual stock” (which can be understood as “future stock”) and “available stock” (which can be understood as “non-reserved” stock). These concepts are very useful to have an overview of products availability analysis and projection in the supply chain.

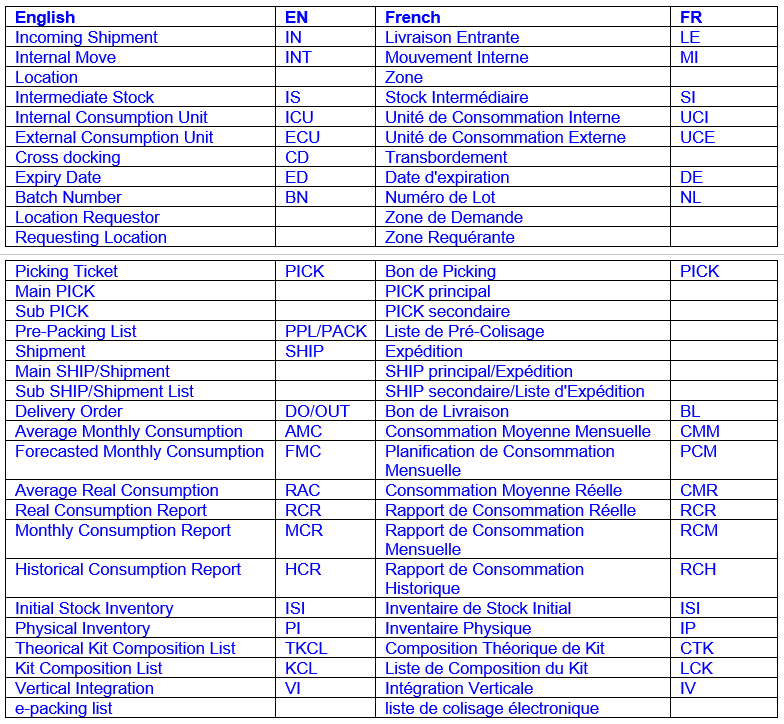

Throughout this chapter, you will find many acronyms. They are mostly used to shorten English words but can be used in the English manual or the French manual (i.e. you may find the acronym PPL in the French version of the manual). In the below table, you find the main acronyms used in this chapter with their meaning.

French acronyms, such as the names of the documents in French in a less extend, are barely used. English acronyms and documents names are usually preferred. In the software, references of documents are often built with the English acronyms of the documents (e.g. 18/HQ/MW101/PO00045, PPL/00033-01, OUT/00028,…), independently of the language in which the software is used.

The language in which UniField is developed is English. The software is then translated in French. That’s the reason why, even if you are connected in French, you could still find some English terminology (on screens, in messages…) while working on UniField. The translation of the software in French is a work in process and some improvements are still needed on this side.