Supply User Manual ENG -> 5. Warehouse -> 5.13 LU-SU4206: Inventories.

LU-SU4206: Inventories.

B. HOW TO CREATE AN INITIAL STOCK INVENTORY

C. HOW TO CREATE A PHYSICAL INVENTORY

D. HOW TO RE-VALUATE THE COST PRICE/AVERAGE PRICE OF PRODUCTS

Supply User Manual ENG -> 5. Warehouse -> 5.13 LU-SU4206: Inventories.

B. HOW TO CREATE AN INITIAL STOCK INVENTORY

C. HOW TO CREATE A PHYSICAL INVENTORY

D. HOW TO RE-VALUATE THE COST PRICE/AVERAGE PRICE OF PRODUCTS

Supply User Manual ENG -> 5. Warehouse -> 5.12 LU-SU4205 Replenishment Rules -> N. GLOSSARY SPECIFIC TO REPLENISHMENT RULES

RR_FMC: Forecasted Monthly Consumption (the one linked to RR concepts)

RR_AMC: Average Monthly Consumption (linked to RR concepts)

RR_HMC: Historical Monthly Consumption (linked to RR concepts), the actual ‘consumption’ of a specific month in the past (unlike the AMC, which is an average consumption of several months in the past)

Std Dev (xxx): Standard deviation of the value set ‘xxx’, statistical notion which gives an idea of the spread of a data set around the average of this data set. Example: Std Dev (HMC) will be the standard deviation of the HMCs around the AMC.

Coeff Var (xxx): Standard deviation of the value set ‘xxx’ divided by the average ‘xxx’ value. Example: Coeff Var (HMC) will be the standard deviation of the HMCs around the AMC, divided by the AMC. It enables variability comparison between 2 value sets relatively to one another.

OC: Order coverage. Quantity of months to cover

TLT: Total Lead time, Qty of days/weeks/months from date of order calculation (stock take) until availability in requesting stock location. TLT = Internal LT + External LT = Preparation LT + Order Creation LT + Order Validation LT + Supplier LT + Handling LT (see mock-ups)

Preparation LT: time needed before RR cycle begins to do tasks such as complete physical inventories, update FMCs and other related discussions

Order Creation LT: time from user starting to look at next OC period to when IR has been creation

Order Validation LT: time from IR creation until PO validation

Supplier LT: time from validated PO until reception at requested location.

Handling LT: time for customs clearance (e.g. from reception at port to reception at Instance Warehouse (can be zero e.g. for internal suppliers)

SS: Safety stock in months of consumption

TCRP: Time Covered by Replaced Product. When a product replaces an older product, this is the duration before the product to be replaced reaches Stock = 0.

Buffer: (additional or alternative) Safety stock as quantity

STDate: Stock take date (most of the time, this is the order calculation date)(this date is a point in time and can be considered as point 0 or starting point/date for calculations below)

RDD: Requested Delivery Date of the order being currently calculated. The default theoretical RDD in FMC-segments equals ‘STDate + TLT’

SODate = Stock Out Date. Date when the estimated projected stock will reach 0 (using RR_FMCs)

Real Stock: this including all current Qty in stock including reserved stock but not already expired stock: It includes all physical stock (including Buffer and Safety stock)

Reserved Stock: all AVAILABLE lines in PICKs and OUTs (current definition in Unifield 13)

PAS: Projected Available Stock. This gives forecast/projection at stock availability at end of TLT, which is the RDD. (reserved stock is not separated out in this calculation)

IOH = Inventory On Hand = Real Stock

MissQty = Missing Quantity (aka Qty lacking) before order arrival

Supply User Manual ENG -> 5. Warehouse -> 5.12 LU-SU4205 Replenishment Rules -> M. HOW TO GENERATE A PRODUCT LIST CONSISTENCY REPORT

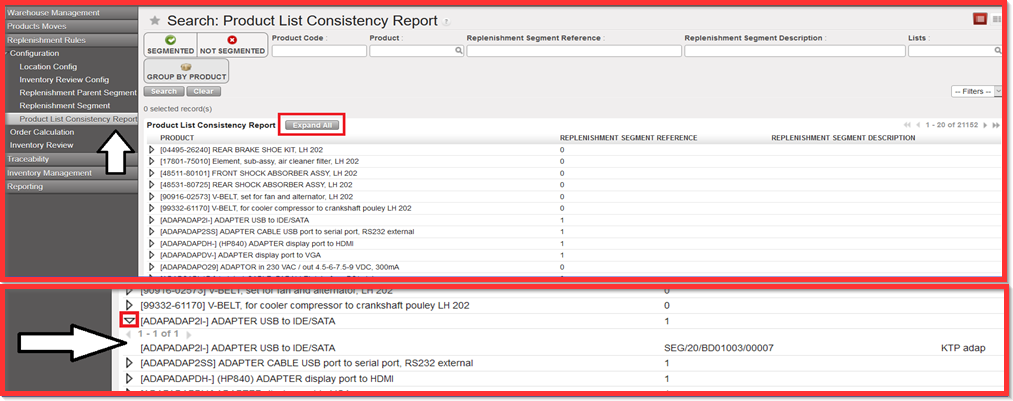

Go to: Warehouse /Replenishment Rules/ Configuration/ Product List Consistency Report

Product List Consistency Report is used for each of the products from RR. The purpose of the report is to cross check products to which segment belong to. It enables to see how many Replenishment Segments each product is in (overview) or whether it is not in any Replenishment segments. It considers only lower level of segments – Replenishment segment (child segments) where the products are added. Thus “Replenishment Parent Segment” is not part of Product List Consistency Report.

If you click on the small arrow at product line level you get the breakdown on clicked product only.

Supply User Manual ENG -> 5. Warehouse -> 5.12 LU-SU4205 Replenishment Rules -> J. HOW TO GENERATE AN ORDER CALCULATION

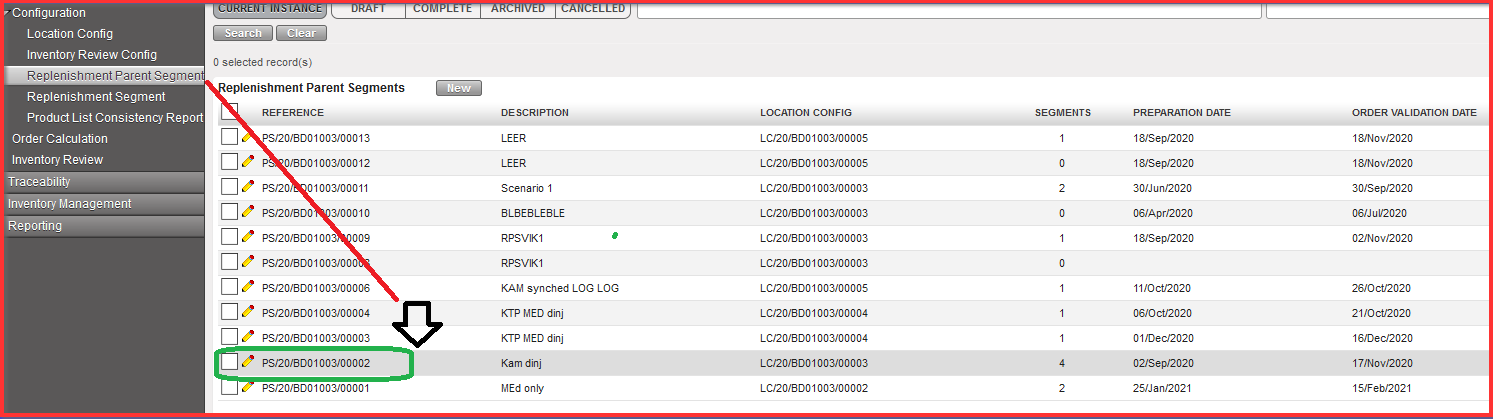

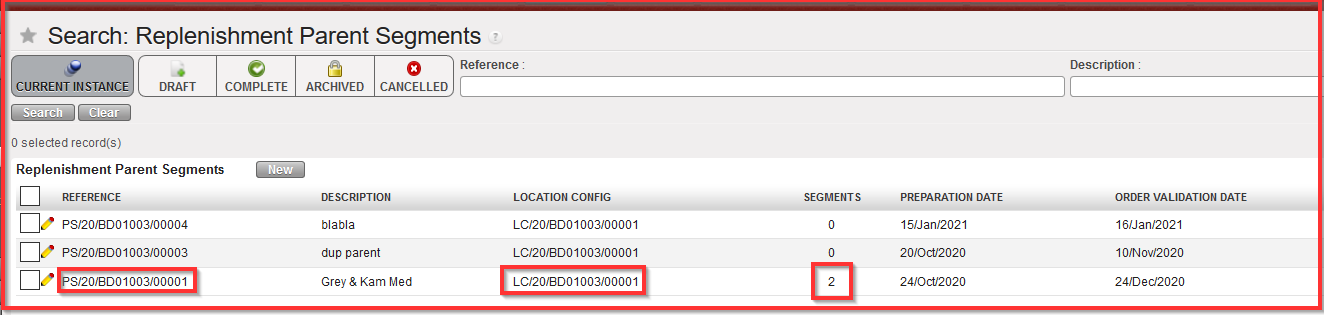

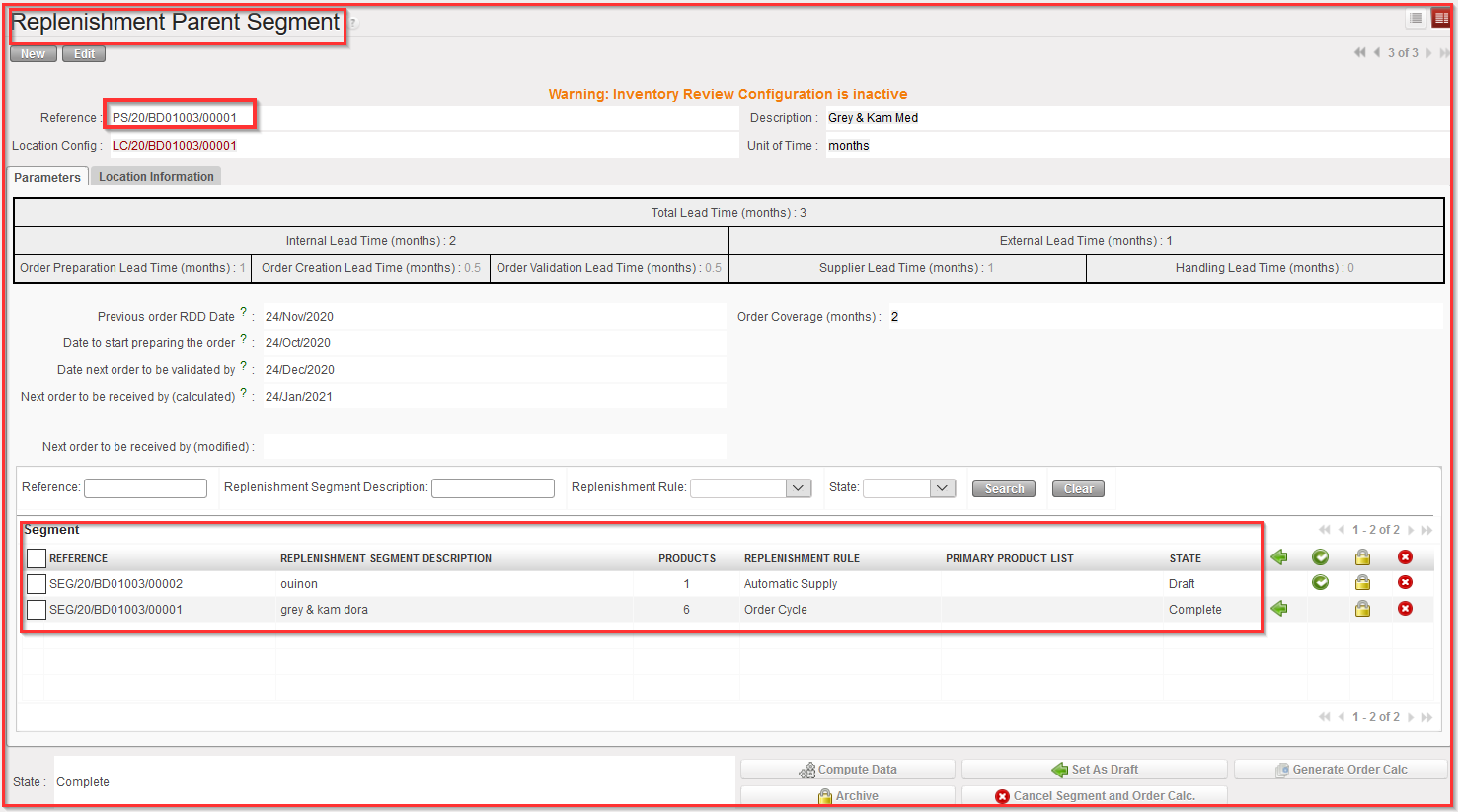

Order Calculation enables to export “IR” and “PO” based on configured “RR” steps before. In order to generate Order Calc go back to “Replenishment Parent Segment” and select Replenishment Parent Segments REFERENCE which exists there and which you need to process.

Go to: Warehouse / Replenishment Rules / Configuration / Replenishment Parent Segment

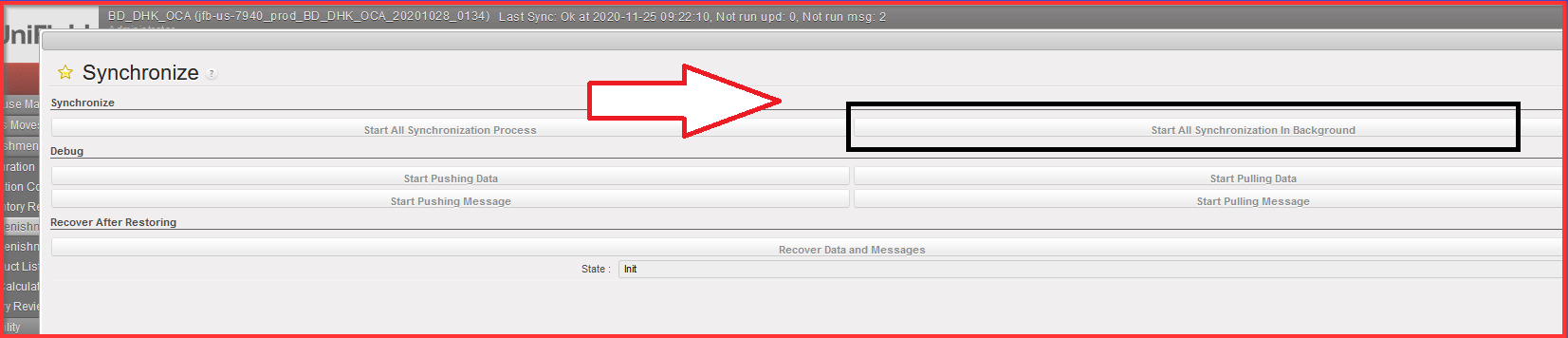

2. Synchronize the instances.

In case you cannot wait until the next automated synchronization, proceed to a manual synchronization (see UM Chapter 2 Configuration> LUSU1103 Synchronization> C.How to Synchronize manually).

Please note that manual synchronization is subject to specific User right; liaise with your IT officer if needed.

Once synched, go back to Replenishment Parent Segment screen.

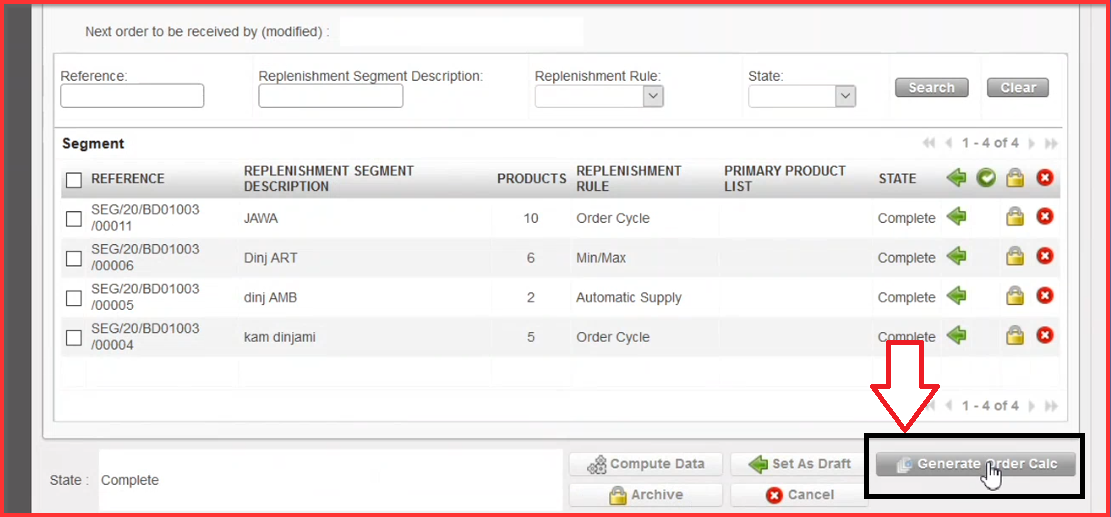

3. Click on “Generate Order Calc” button.

When button is clicked it will generate and Order calculation for all lines included in all “Complete” state (child segments) belonging to the Parent Segment. When Button is clicked there is a message indicating that Order Calc has been generated for XX YY and ZZ (child) Segments.

The export from the Order Calc will also contain all lines from segments belonging to the Parent Segment. Once attached to a parent segment a child segment cannot switch its parent. If a Child segment is Archived, it is not considered Active.

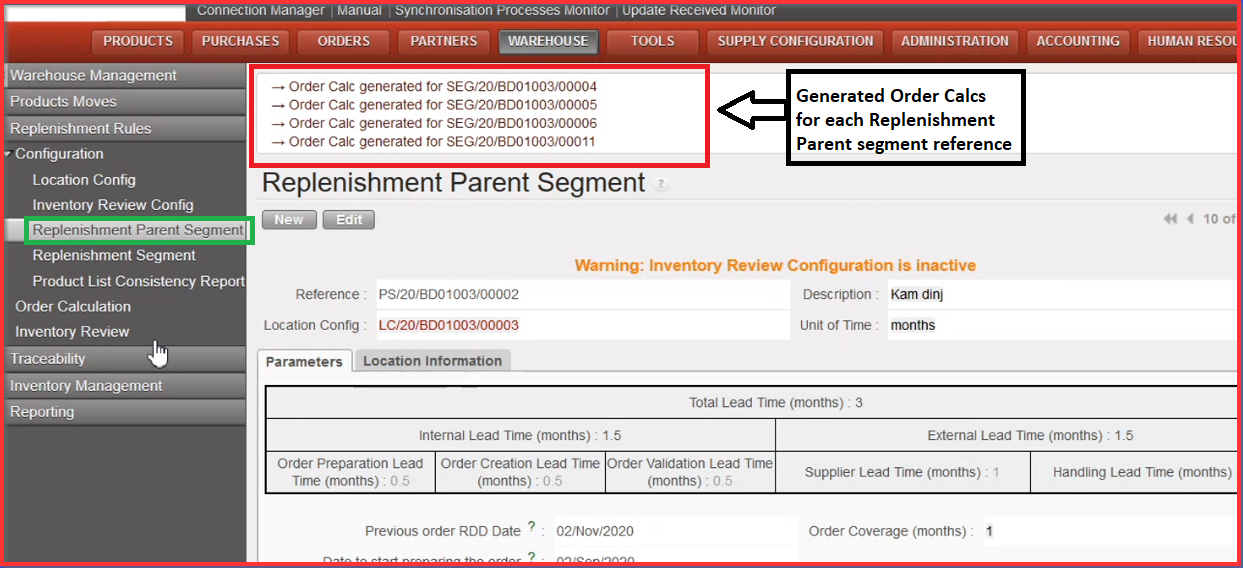

After the clicking on “Generate Order Calc” button you get the notification message on the top of the “Replenishment Parent Segment” screen informing about generated Order Calc. It automatically generates for all Replenishment Segment References (all lines).

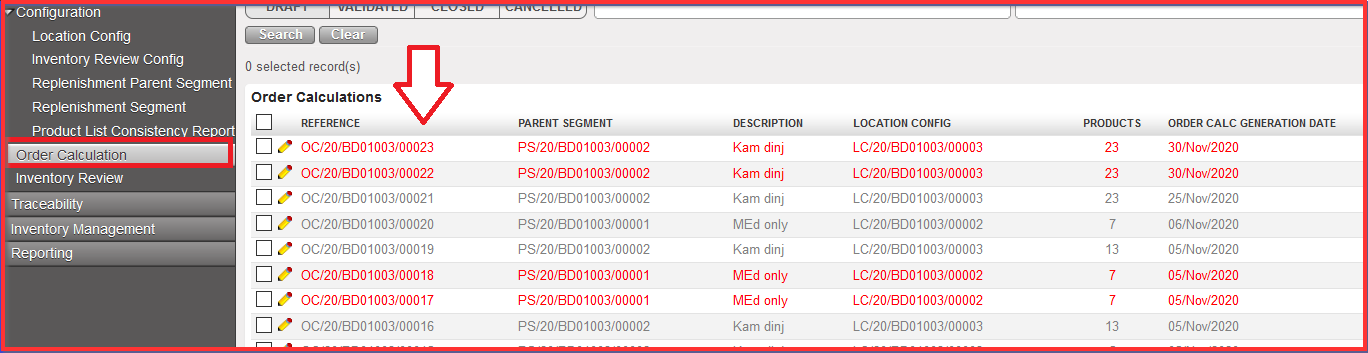

4. Click on “Order Calculation” submenu option. There are created generated Order Calcs on the top of the screen in “draft” status.

5. Click on the “OC” reference which you need to process

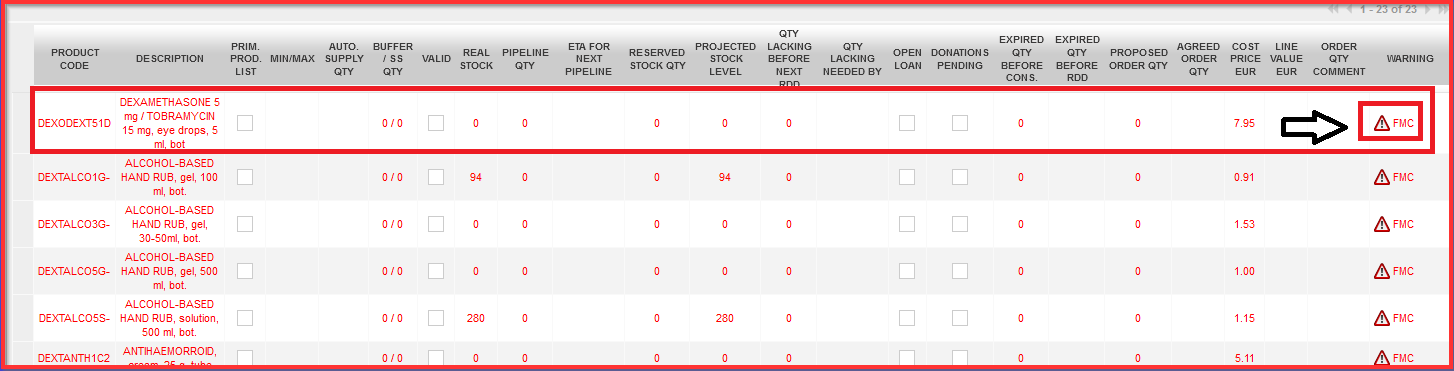

There are multiple product lines visible. If there is invalid “FMC” the product code line is in “red” and there is an exclamation mark depicted in “Warning” column. Invalid FMC goes with wrong data when FMC is not calculated correctly which is a huge blocker in terms of calculating and processing IR to PO. Order Calcs must be processed only with correct FMC.

6. Update the Order Calc (if necessary)

a) Fix FMC correctly by correcting input values in “Agreed Order Qty” column. Column cells for “Agreed Order Qty” must contain at least “zero” value. Blank cells are not allowed.

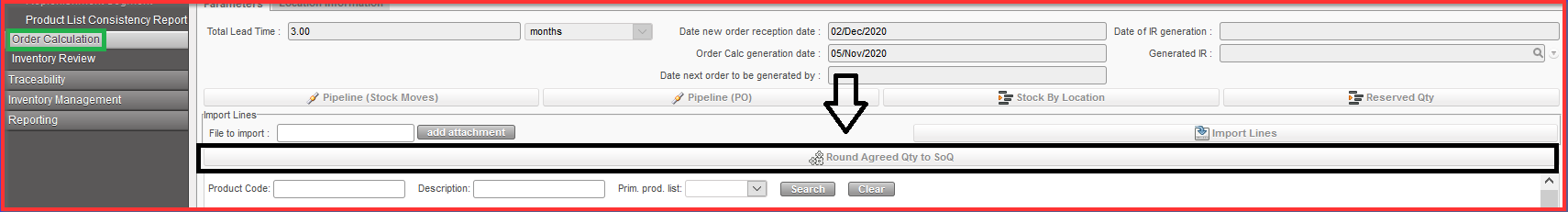

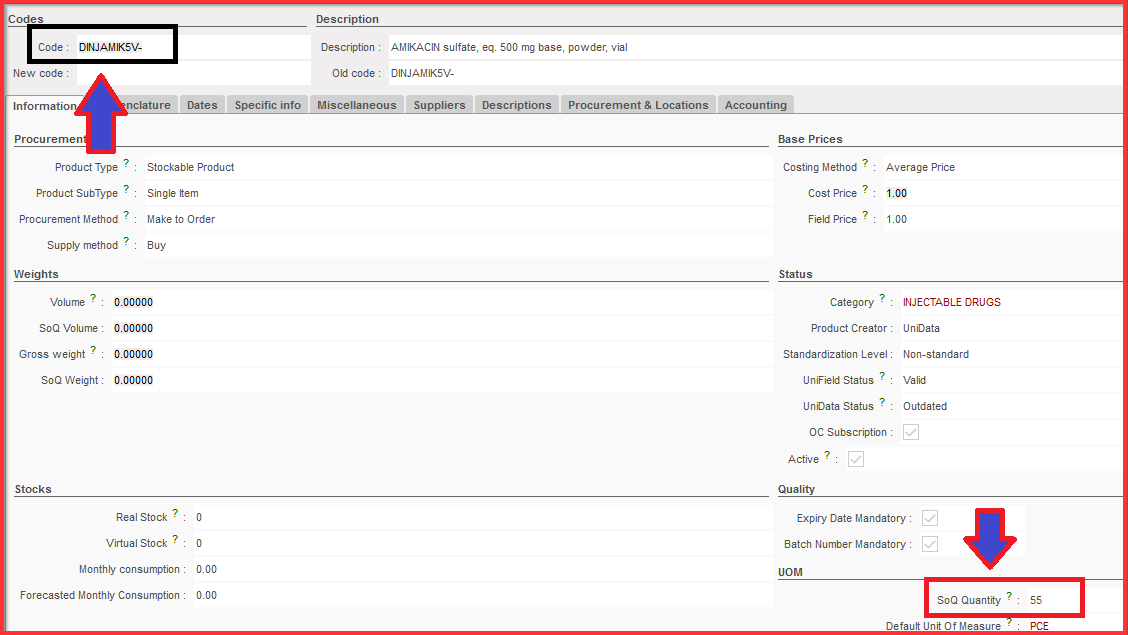

b) Click on “Round Qty to SoQ” which will round up the quantities in the “Agreed Order Qty” according to any SoQ value found in the Product PMD in main instance.

This “Agreed Order Qty” column is a main pillar for further validation process. The validation process needs to be done at this point which means that cost price is taken from the product PMD (data sheet) e.g. average Cost Price is not computed based on the supplier selection at this stage. Proposed Order Qty. can be changed due to the type of packaging. This is a manual action only. If Product PMD has SoQ of “1” then no rounding to be done. If proposed Qty is “0” then no rounding to be done. “Proposed Qty” value is not impacted by this button and should stay as per original value.

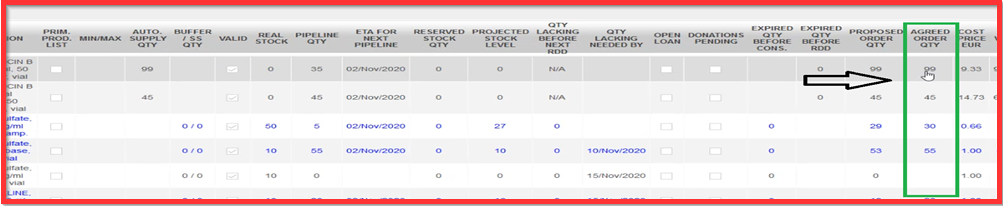

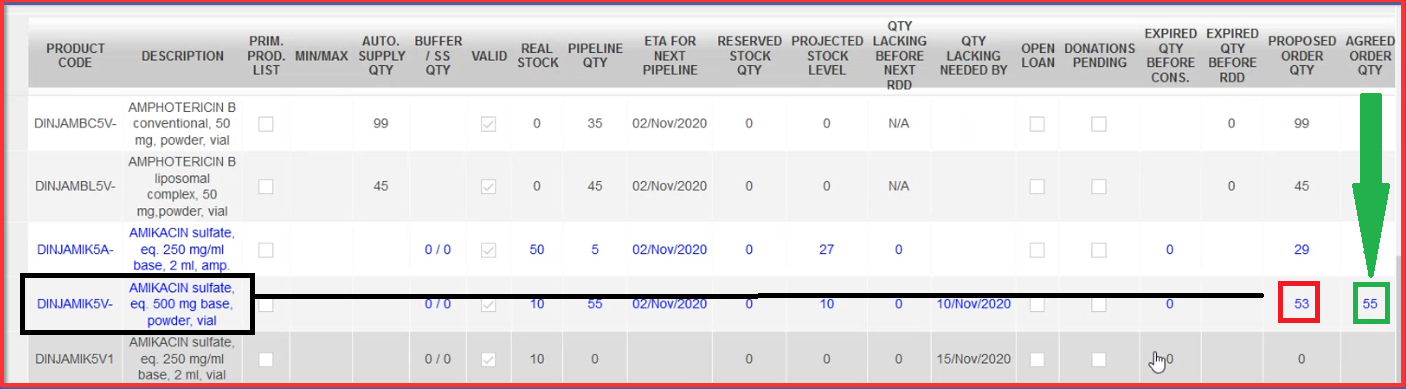

Where this button has been used and the qty has been changed (rounded up), the line should appear in a different color (blue) onscreen and in export report. The Cost price (X) is still based on this “Agreed order Qty” and so will take any rounded up qty into account. Below picture shows the quantity of products in “Proposed Order Qty” column which is rounded up for the quantity set out in “Agreed Order Qty” column.

You can go to Products > Products “Search: Products” section and check “SoQ Quantity” for the specific product code in related product data sheet under UOM (Unit of measurement) section.

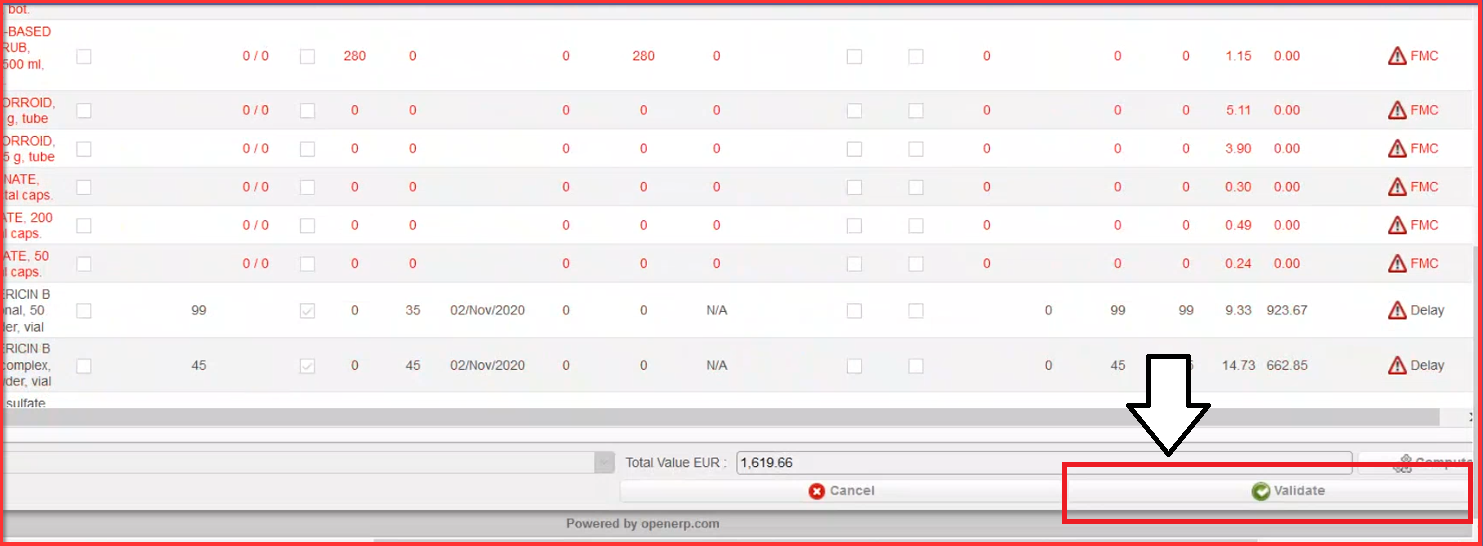

7. Back to the Order Calc screen, when values are fixed for each product line, click on button “Validate”.

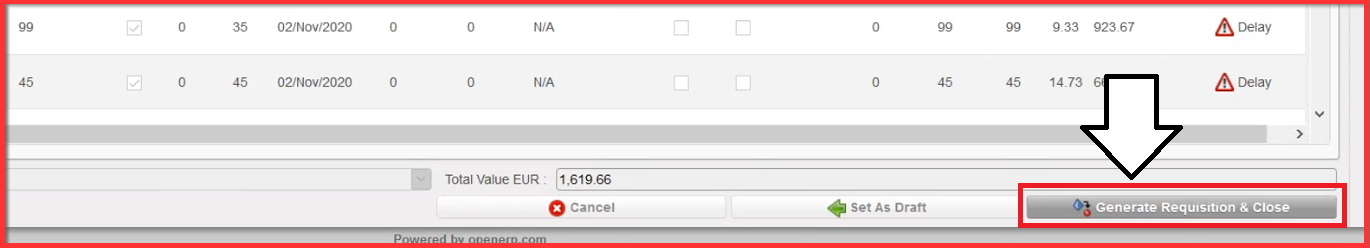

8. Click on button “Generate Requisition & Close”.

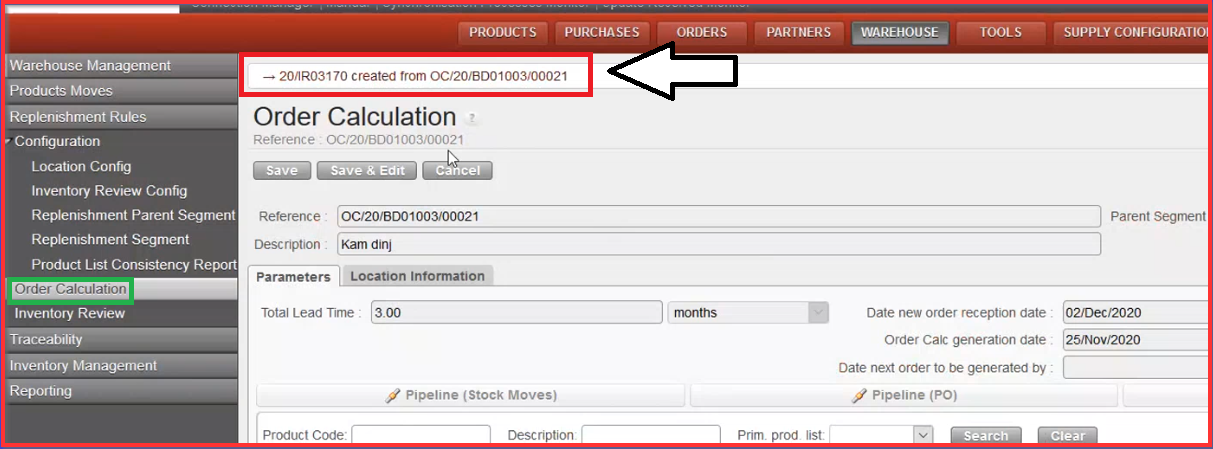

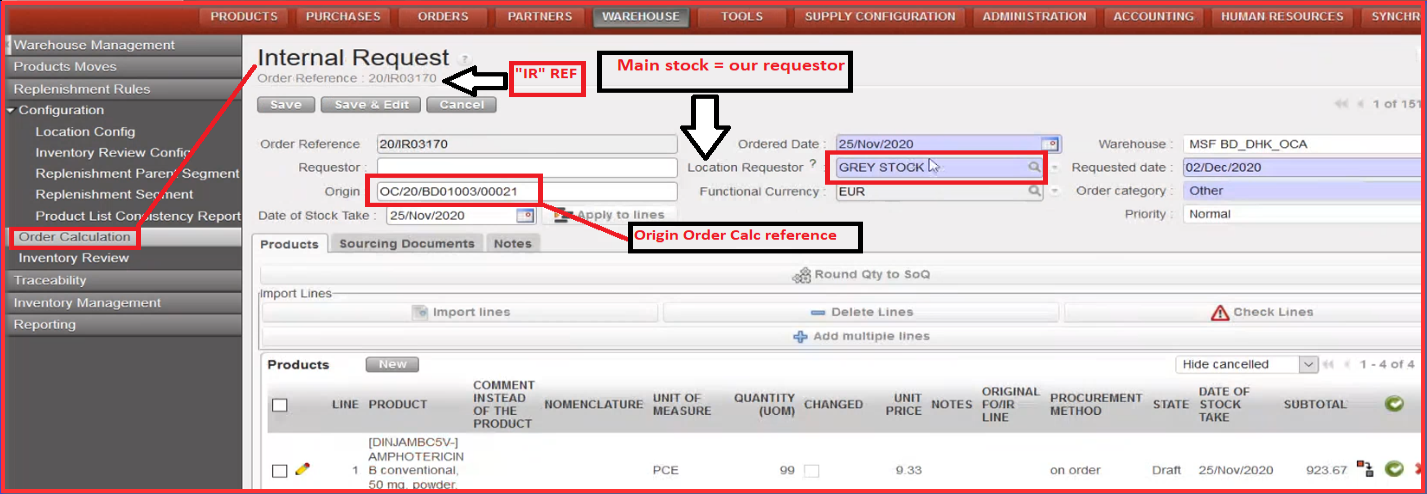

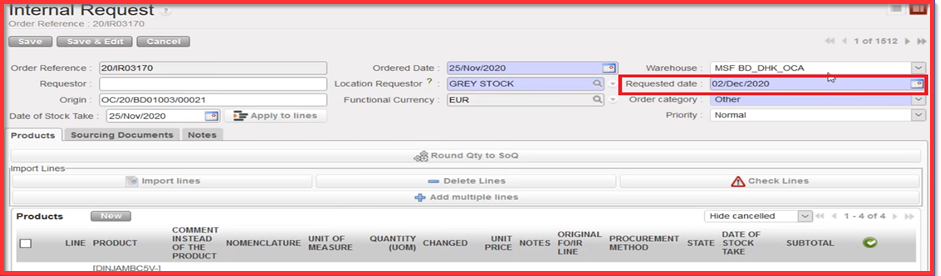

When you click on “Generate Requisition & Close”, the Order Calc is Closed. There is a new message on the top of the screen informing us about newly created IR (e.g. 20/IR xxx) reference from specific Order Calc reference (e.g. OC/20/BDO xxxxx) as depicted below on print screen example.

9. Click on created IR reference on the top of the screen to be redirected to the “Internal Request” screen

The “Replenishment Parent Segment” and “Replenishment Segment” are updated based on created “IR”, next order is due by e.g. “Date new order reception date” section depicted below.

See below the description of the sections in opened new Internal Request window.

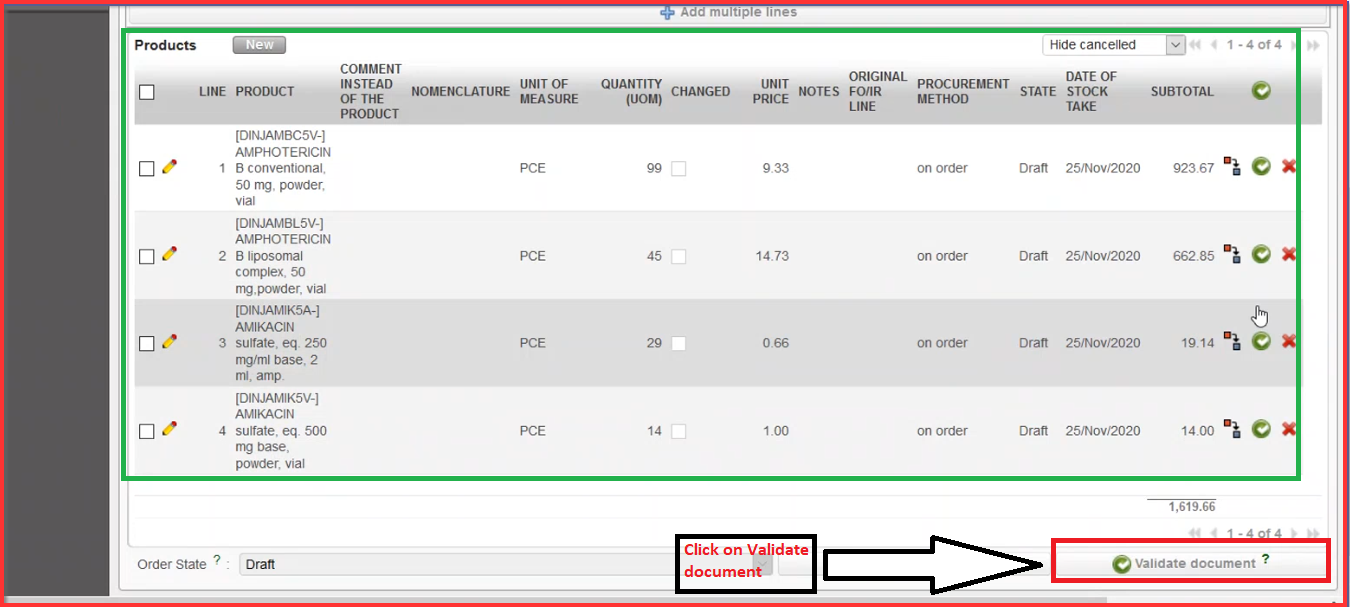

10. Click on “Validate document” on the IR screen.

After the validation process, there is still option to change “Requested date”. This date is used in PO phase in order to determine “RDD” date. There is no update backwards but only onwards feasible. When you get to PO stage as soon as you have validated lines, there will be considered as pipeline.

Supply User Manual ENG -> 5. Warehouse -> 5.12 LU-SU4205 Replenishment Rules -> I. HOW TO REVIEW A REPLENISHMENT PARENT SEGMENT

Go to: Warehouse / Replenishment Rules / Configuration / Replenishment Parent Segment

As you can see on the example below, the number “2” in Replenishment Parent Segment column shows how many Segments have been created (i.e.: related to this Parent Replenishment Segment).

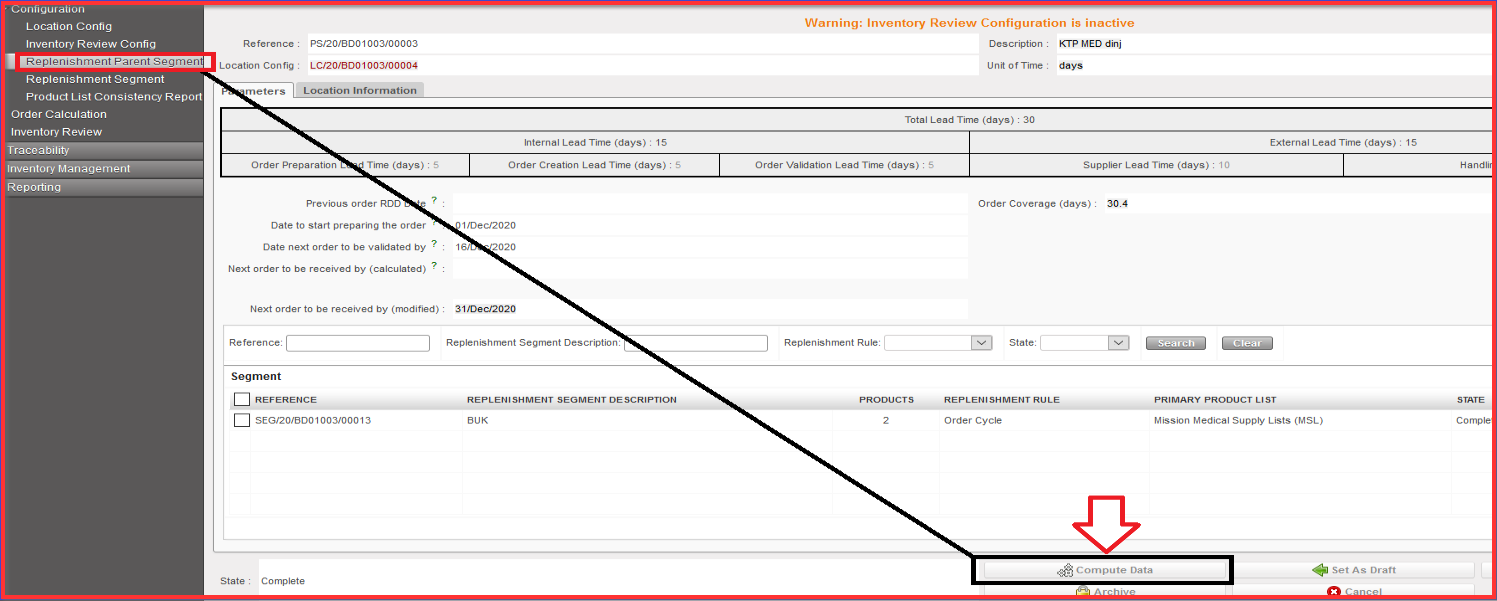

Parameters tab

If you click on Parameters tab, you get following screen (see picture below) where in addition to the information set at creation (see chapter D. How to create a Parent Replenishment Segment) you will be able to see the added “Replenishment Segment” created afterwards.

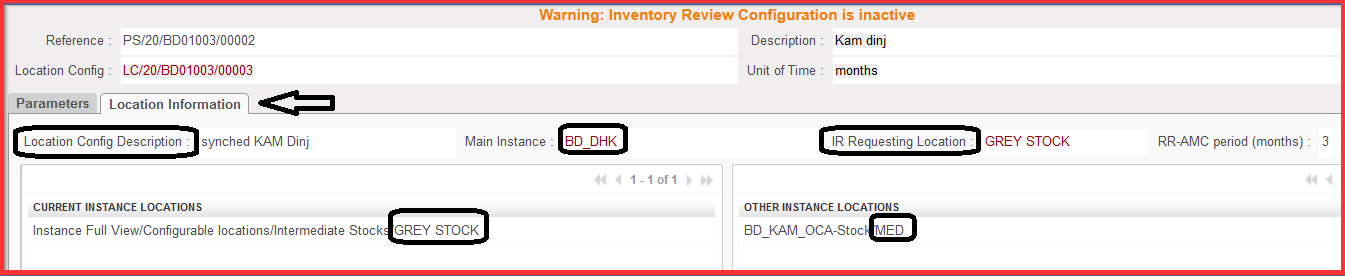

“Location information” tab

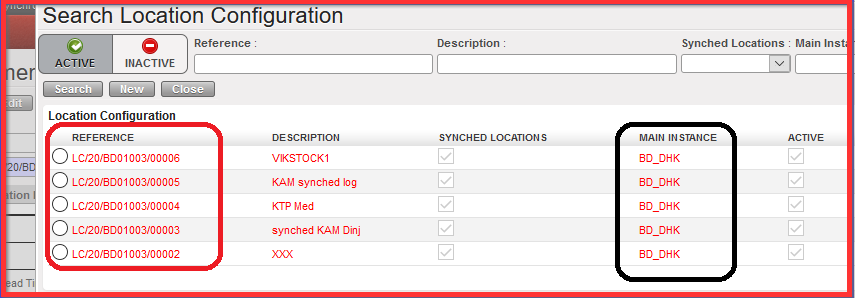

The Replenishment Parent Segment only looks at the same location config. Therefore, all the defined “child” SEGMENTS underneath this Parent Segment will use the same location config.

You can see in the “Location information tab”, as depicted below, that there is GREY STOCK under current instance locations and MED on the project level. We can see also Location Config Description which was setup in Location Config step before. There is also Main Instance BD_DHK and IR Requested Location (Grey Stock), which means that IR will be always generated with the requested location on parent level (i.e.: the goods will be delivered to the “Grey Stock” Location).

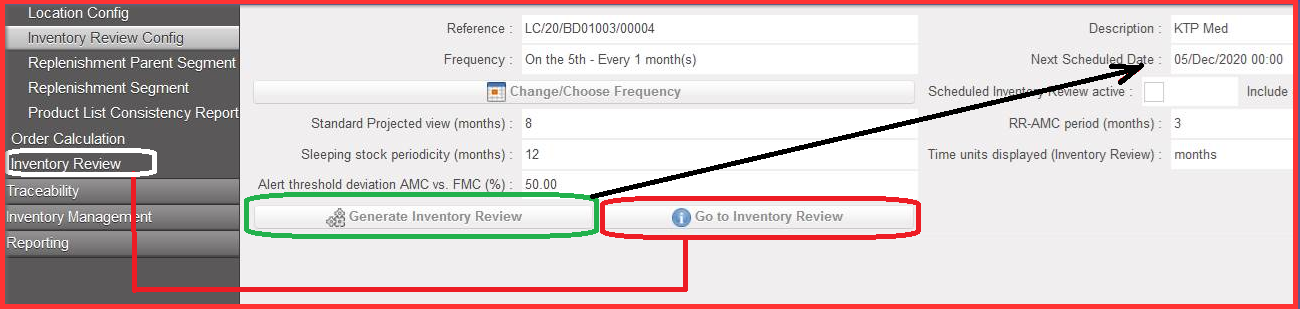

Supply User Manual ENG -> 5. Warehouse -> 5.12 LU-SU4205 Replenishment Rules -> G. HOW TO GENERATE THE INVENTORY REVIEW

Go to: Warehouse / Replenishment Rules / Configuration / Inventory Review Config

2. Click on “Generate Inventory Review”.

Please note that it is the manual version of generating the report but that you can actually wait for configured/ automated “Next Scheduled Date”.

3. Click on the button “Go to inventory Review” or click on Inventory Review in the sub menu on the left-hand side.

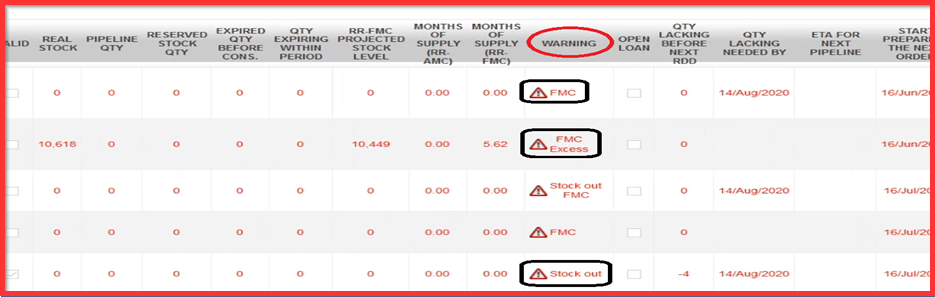

4. Check the value in column “WARNING”:

a) “Product is not in any related segment, only in stock / pipeline of location”

b) “FMC”: linked to Inventory Config review where you set up how many projected months cover the period. FMC alert here means that in the segment does not cover the period.

c) “Excess”: excess stock is linked to the order cycle which is put in. What is calculated beyond that period is considered as extra stock (excess). Excess stock calculation considers “Inventory on hand”, “pipeline arriving” and “expiries arriving before the end of upcoming (next) OC period”, i.e. Projected Available Stock.

d) “Stock Out”: considered before next RDD (Requested Delivery Date) which is the issue. Basically, there are no items available to fill the expected stock need.

e) “Pipeline in the Past“: where a pipeline delivery has its confirmed delivery date in the past

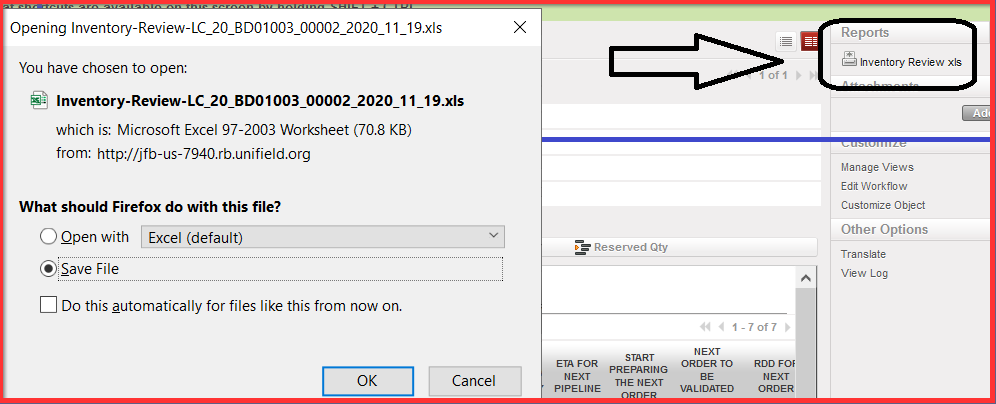

Please note that the Inventory Review can be exported via Excel by clicking on the icon “Inventory Review xls” on the right side of the panel menu.

Note: in this export the values in the months of supply (RR-AMC), months of supply (RR-FMC) & Projected MX (month) are rounded to 2 decimals.

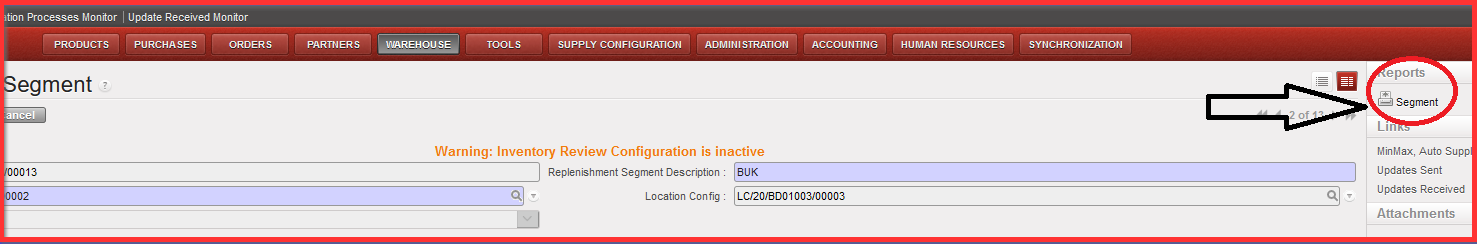

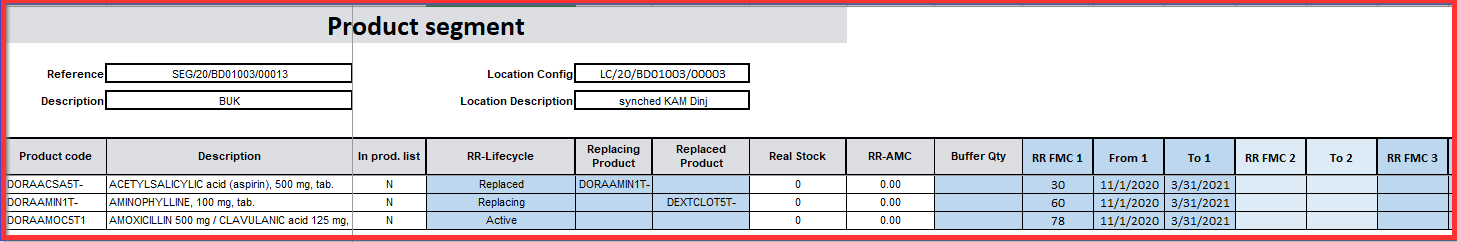

Supply User Manual ENG -> 5. Warehouse -> 5.12 LU-SU4205 Replenishment Rules -> F. HOW TO EXPORT/IMPORT PRODUCT SEGMENT EXCEL SPREADSHEET

A Product Segment Excel file can be exported also to be re-imported and fill in the data (when Replenishment Segment is in Draft).

Go to: Warehouse / Replenishment Rules / Configuration / Replenishment Parent Segment

Excel spreadsheet Product segment report.

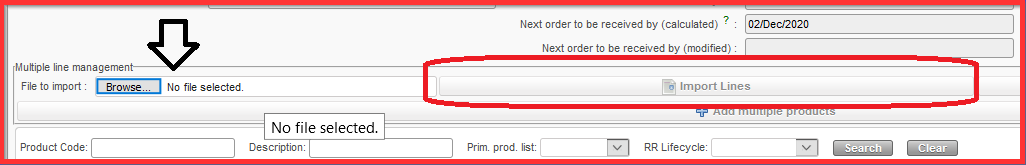

2. You can adjust the excel spreadsheet file, adding inputs and expected updates and import it back through “File to Import” / “Add attachment” button as depicted below.

Supply User Manual ENG -> 5. Warehouse -> 5.12 LU-SU4205 Replenishment Rules -> D. HOW TO CREATE A NEW REPLENISHMENT PARENT SEGMENT

Replenishment Parent Segment section provides an overview of relevant Replenishment segments and products below it, which have defined parameters columns. It is a prerequisite to be processed before the next step which is Replenishment Segment.

New “Parent” segment permits and allows to have an overview of Segments with similar characteristics / conditions. Replenishment Parent Segment is the third step in UF after Inventory Review Config and must be completed before the next step (Replenishment Segment)

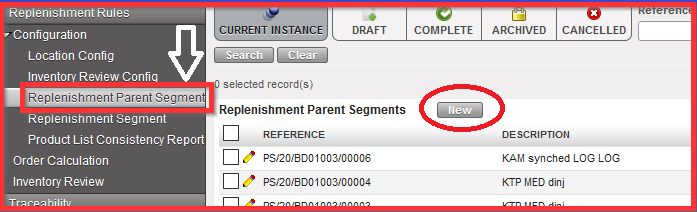

Go to: Warehouse / Replenishment Rules / Configuration / Replenishment Parent Segment

1.Click on “New” and open the window

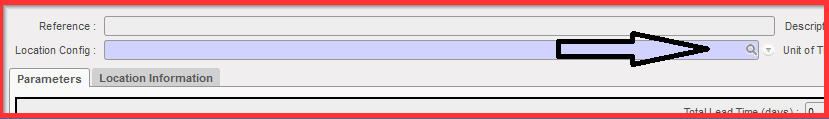

2. Select the “Location Config” reference which was created in the first step (Location Config)

3. Fill in your Description

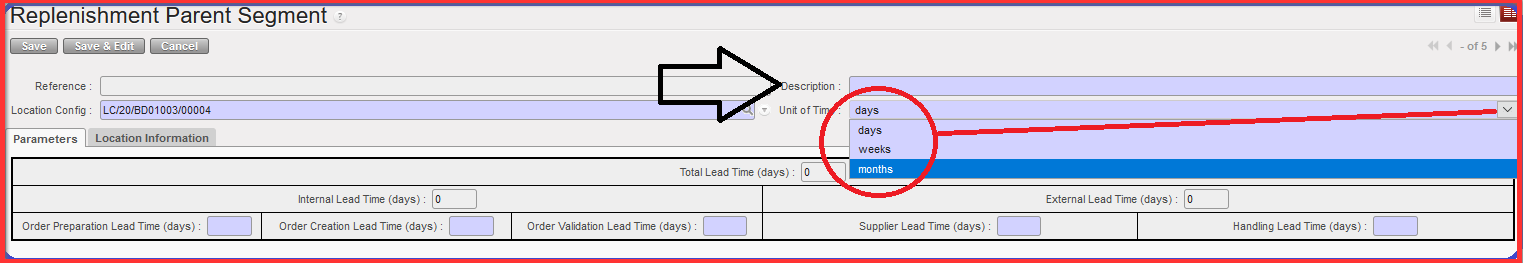

4. Define Unit of Time in days, weeks or months:

It will be automatically projected to all Parameters listed below, i.e. selected option “months” automatically defines “months” value in all following sub categories Lead Time, Internal Lead Time, External Lead Time) and is visible in the brackets (months) as depicted on the screen below.

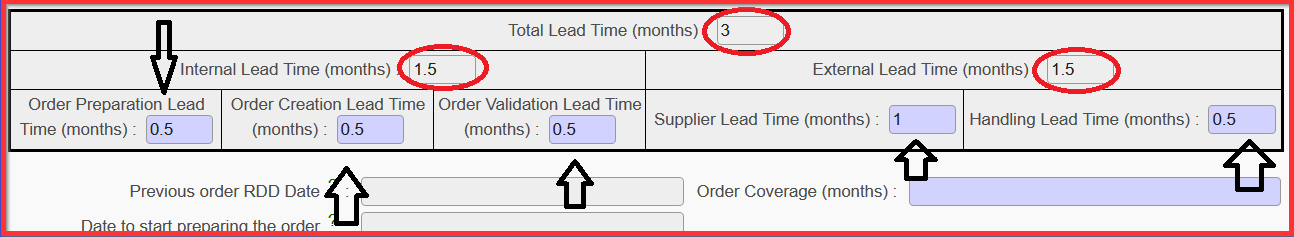

5. Add your Lead time values (predefined in months in the example below and decimals are accepted):

a) Internal Lead Time:

i) Order Preparation Lead Time: covers the time of pre-work to be done by people in charge of: checking the system to have correct values; physical inventory; possible check or adjustment of FMC…

ii) Order Creation Lead Time: It is the time when order calculation has been generated to when the IR has been created. It starts when the user click on that button in a segment and it is the time they need to look what order calculation has proposed in terms of quantities. Basically, the time when IR is created is the same time when it is validated.

iii) Order Validation Lead Time: time from IR creation until PO validation

b) External Lead Time:

i) Supplier Lead Time: time from validated PO until reception at requested location.

ii ) Handling Lead Time: time for the handling (customs brokerage) e.g. from reception at port/airstrip to reception at Instance Warehouse. Can be zero e.g. for internal suppliers.

After filling these fields, Total Lead Time, Internal Lead Time and External Lead Time will be automatically computed/ populated.

Total Lead Time = Internal Lead Time + External Lead Time

Internal Lead Time = Order Preparation Lead Times + Order Creation Lead Time + Order Validation Lead Time

External Lead Time = Supplier Lead Time + Handling Lead Time

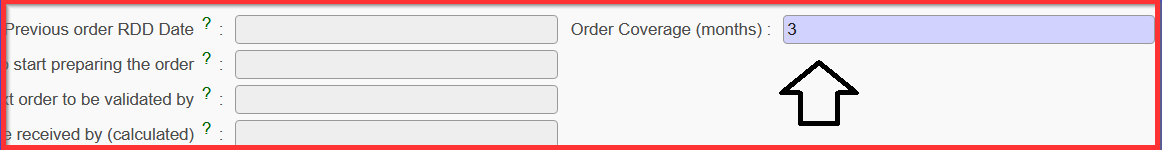

6. Fill out “Order Coverage”: how long we want the ordered products to last for (here preconfigured in months)

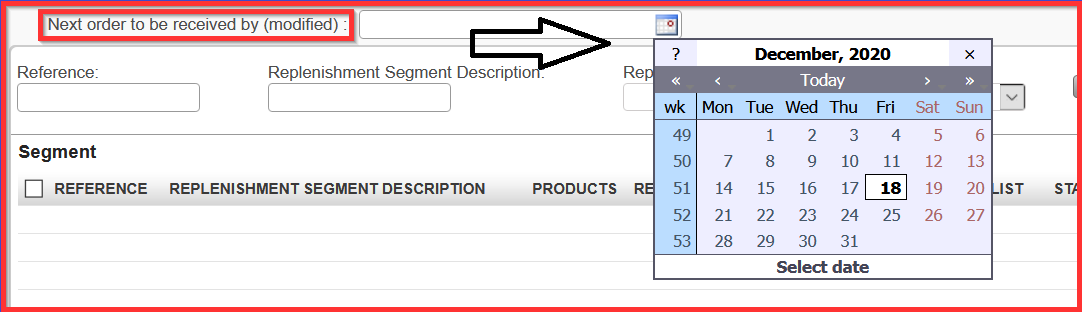

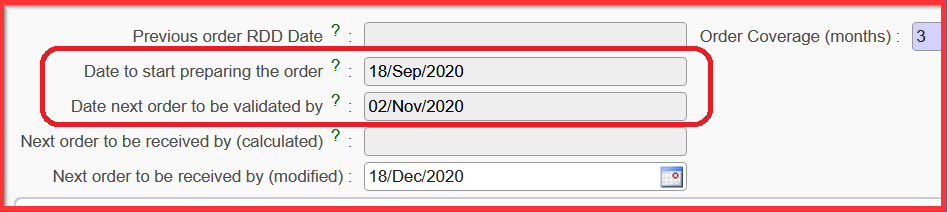

7. Select the date for “Next order to be received by (modified)”. When you select the date, you get automatically computed dates for “Date to start preparing the order” and “Next order to be validated by” e.g. second red highlighted print screen

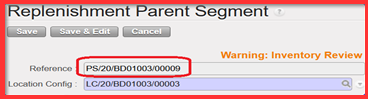

8. Click on “Completed” and you get created Parent Segment Reference, see print screen below

When Replenishment Segments are created (see next Chapter for Replenishment Segment creation) and are linked to specific Replenishment Parent Segment you can come back to the specific Replenishment Parent Segment reference and click on the button “Generate Order Calc” ( see section J. How to generate an Order Calculation).

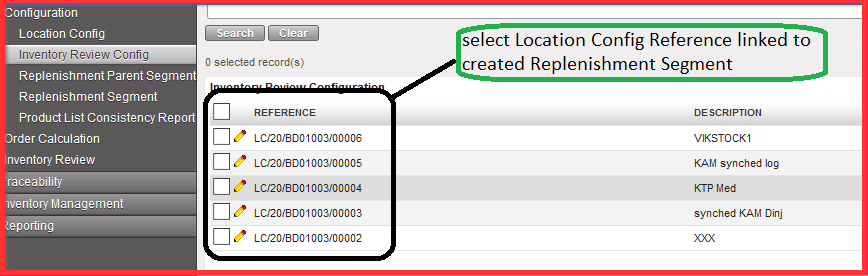

Supply User Manual ENG -> 5. Warehouse -> 5.12 LU-SU4205 Replenishment Rules -> C. HOW TO PARAMETER THE INVENTORY REVIEW CONFIGURATION

Go to: Warehouse / Replenishment Rules / Configuration / Inventory Review Config

It is a configuration of the parameters needed to be shown in a whole inventory review. It is the screen in UF where the parameters are configured which we want to have displayed in the inventory review report after that step.

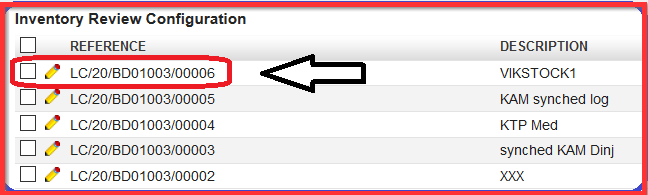

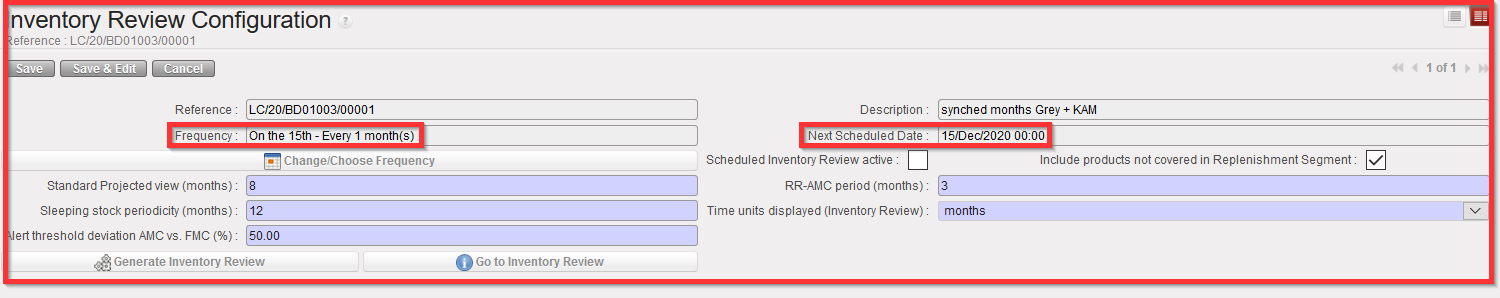

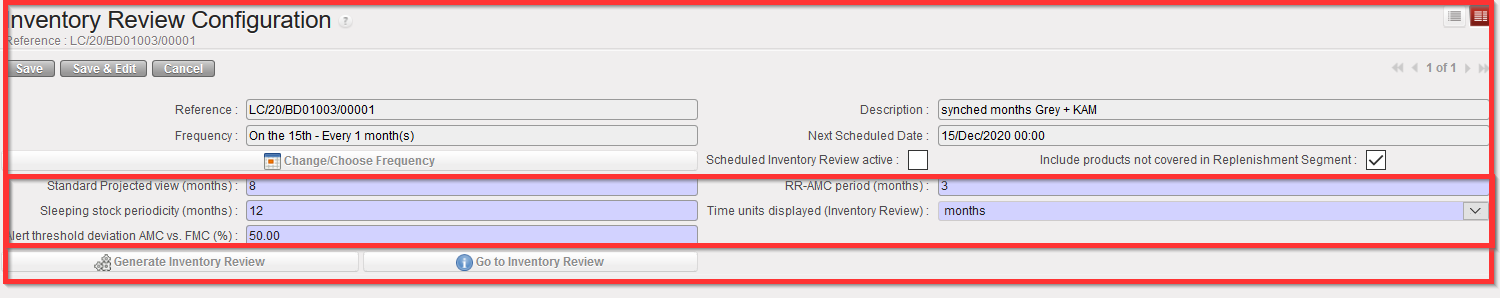

1.Choose the specific Location Configuration reference (created above)) and click on the desired line with relevant reference which is visible in specific format as follows (LC/XXX):

Or you click directly on the pencil ![]() (edit the line) of the needed “REFERENCE” number created the step before in order to get Inventory Review Configuration screen. Here we can decide what we can see in our Inventory Review which is the submenu section of Configuration. Basically, we must set up our needs and configuration in order to get desired output for our RR configuration.

(edit the line) of the needed “REFERENCE” number created the step before in order to get Inventory Review Configuration screen. Here we can decide what we can see in our Inventory Review which is the submenu section of Configuration. Basically, we must set up our needs and configuration in order to get desired output for our RR configuration.

|

|

|

Inventory Review Configuration screen |

2. Click on “Change/Choose Frequency configuration” (see print screen above) in order to determine the choice of the frequency; how often the inventory review report is generated.

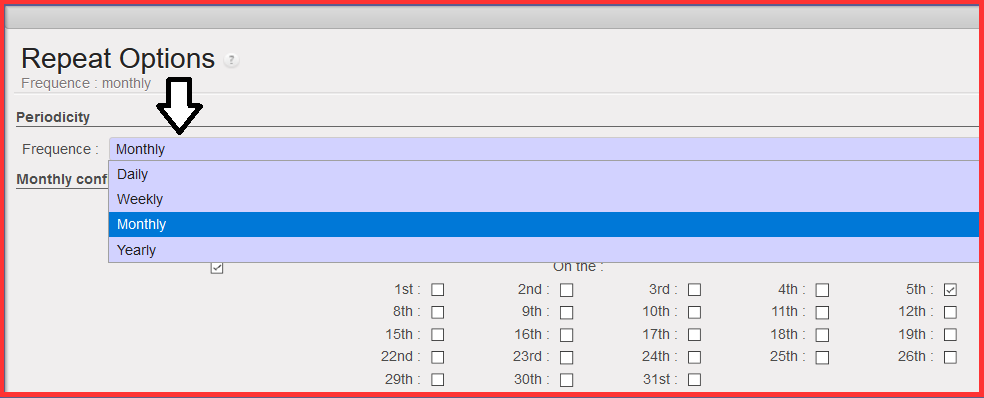

3. Chose “Periodicity” from the drop down list from the popup screen “Repeat Options” (see below): Daily, Weekly, Monthly or Yearly

4. Chose the “Daily/ Weekly/ Monthly or Yearly configuration” (depending on the Frequency you selected above).

a) First select how often you need to generate the report: “Every” 1/2/3…Days/Weeks/ Months or Year.You will have different fine-tuning options depending on the Frequency you chose.

b) You can chose to run the Inventory every Monday/ Tuesday…of a week; or every first/second.. Monday/ Tuesday… of a month; or every 1st, 2d, 3rd…day of a month…

In the example below with the 2d checkbox ticked for a monthly Periodicity and the 15th of each month. The Inventory review will be run every 15th of a month.

|

|

|

Monthly Configuration – every 15th of the month (example) |

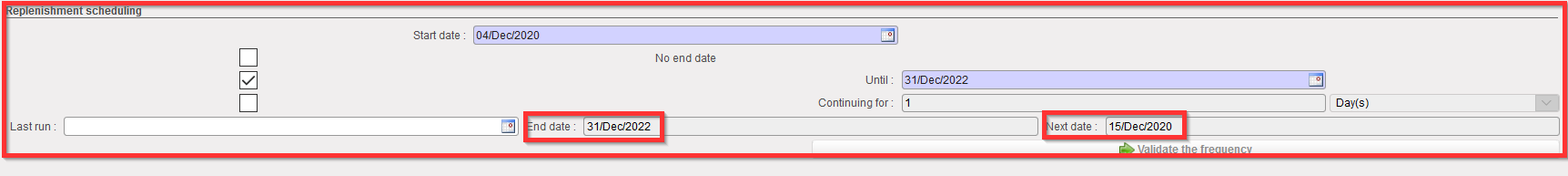

5. Set the “Replenishment scheduling” dates:

a) “Start date” is by default set to the date of the day but can be edited

b) Defines the date range between which the Inventory Review is generated.

i) Set “No end date” (if 1st check box is ticked)

ii) Set “Until” a specific date or (if 2d checkbox ticked) (example taken below)

iii) Set for a defined period of time (i.e.: for 1/2/3…days/Weeks/ Months or Years) by filling the “Continuing for” fields (if 3rd checkbox is filled)

The next ordering date will be updated at the bottom of the screen when it is validated in the “Next Date” field. Selected date is the start of the repeat options cycle.

|

|

|

Replenishment scheduling – from 04/Dec/2020 till 31/Dec/2022 (example) |

6. Click on “Validate the frequency”. You will be directed back to the “Inventory Review Configuration” screen. Note that the “Frequency” and “Next Scheduled Date” have been updated.

NB: if you click again on “Change/ Choose frequency” and go back to the “Repeat option” pop up, you will see that the “End date” and the “Next Date” have been updated as well.

7. Back to the “Inventory Review Configuration” screen, the fields below all have a default value that you can/should review/update to customize your needs (see print screen below):

a) Standard Projected view (months): how far in the future the report will show us

b) Sleeping stock periodicity (months): if the products have no consumption for last (xxx months). Usual default sleeping stock periodicity configuration is 12 months.

c) Alert threshold deviation AMC vs. FMC (%): defines the difference of what we projected in our forecast and what is the actual committed status of the consumption based on the operations of relevant unit. It is configured based on the supply unit needs and alignment among the field stakeholders. Default ratio used for the scenario is value of 50.00.

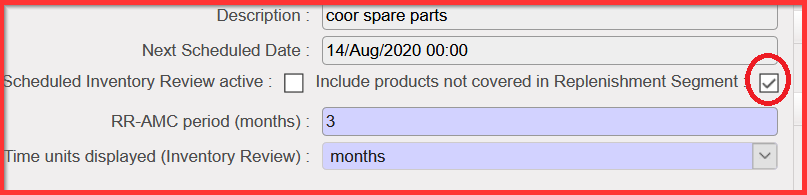

d) RR-AMC period (months): number of months taken into account for the RR-Average Monthly Consumption calculation (please note that the RR-AMC is different from the AMC in the rest of the system since it is specific to the configured location)

e) Time Units displayed (Inventory Review): filter option to get displayed in months, weeks or days

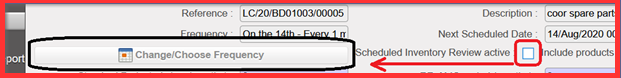

f) Scheduled Inventory Review active (checkbox): if ticked it means that inventory Review Configuration will be generated according to “Change/Choose Frequency” option chosen.

If you untick it will be generated manually by user.

g) “Include products not covered in Replenishment Segment” (checkbox): if ticked (default) it includes every product in Location selected.

If unticked, it only includes the products in Replenishment Segment (to be explained in chapter below).

If the user unticks it means that all products (no matter what the user selects in created Replenishment Segment) in location which the user selected be also in the report. It means e.g. if you select particularly something like category “MED” it means the generation of all linked products to that category and it makes the report much larger. It might be useful to get entire overview of the products within that specific location, which is very good for planning purposes.

Supply User Manual ENG -> 5. Warehouse -> 5.12 LU-SU4205 Replenishment Rules -> B. HOW TO CONFIGURE A LOCATION

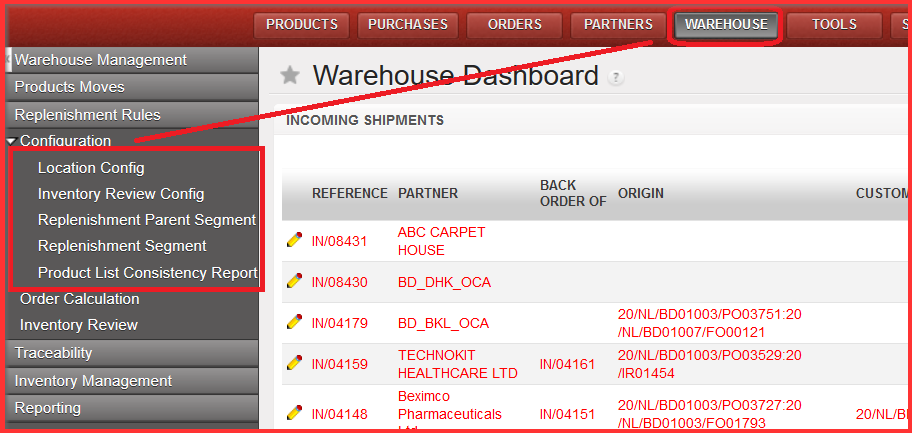

Go to: Warehouse /Replenishment Rules/ Configuration

Configuration sub menu options: Location Config, Inventory Review Config, Replenishment Parent Segment, Replenishment Segment, Product List Consistency Report

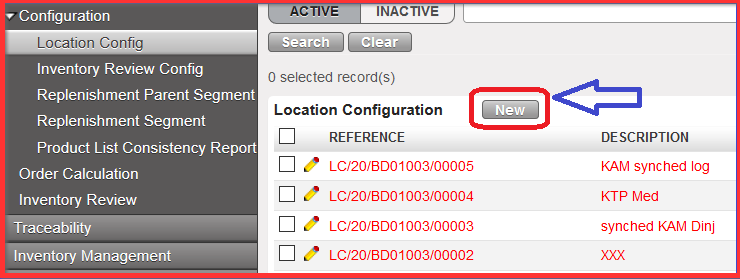

Go to: Warehouse / Replenishment Rules / Configuration / Location Config

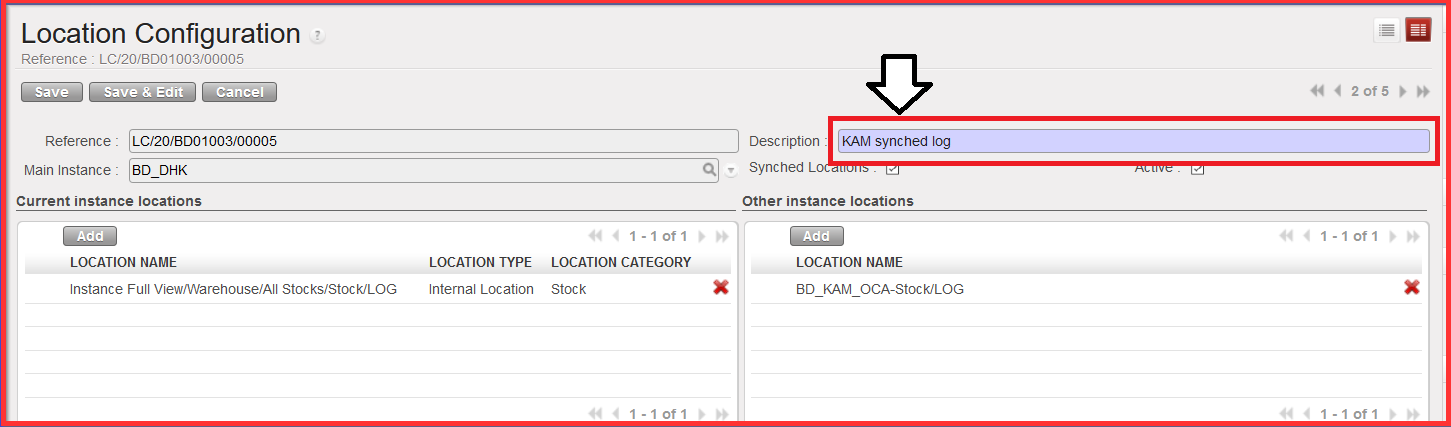

1.Click on button “NEW” to create a new record.

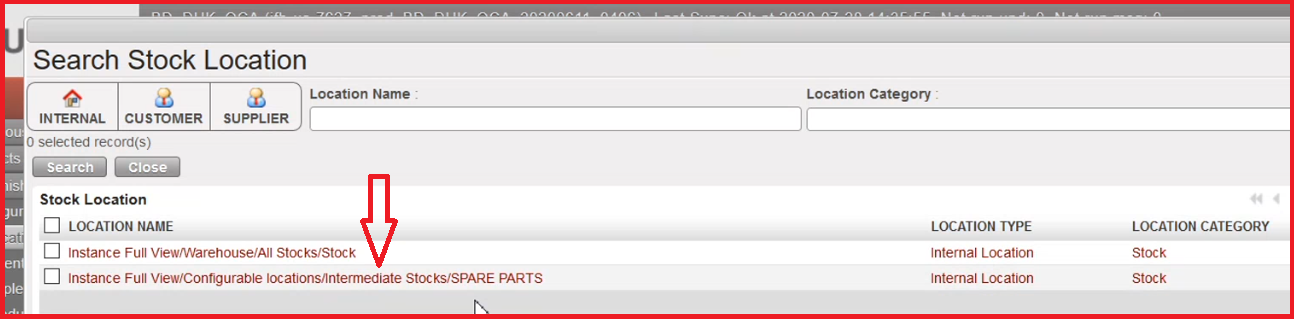

2. Click on “Add” under the “Current Instance location” part to choose a Stock location from your main instance.

This is the location which belongs to “Main Instance” (automatically populated at creation of Location Configuration) where the RR is created. This location must exist in the system and be a real instance.

|

|

|

Main Configuration Location – Current instance locations |

3. Select the Stock Location

4. Fill the “Description” field with a meaningful name

5. Click on “Add” on the “Other instance locations” section in case you need to configure location form another instance as well (OPTIONAL).

Indeed this action will be available only if the “Synched Locations” checkbox is ticked (automatically by default). Synched Locations are linked to “Other Instance locations” which are subordinated to Current Instance Locations (i.e.: project instances linked to COO). This means that this option is only available at COO level.

|

|

|

Main Configuration Location – Other instance locations -Synched locations ticked |

NB: If you untick “Synched Locations” checkbox, “Other Instance locations” won’t be available anymore.

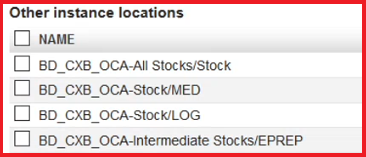

6. Choose the other sub-instance locations (you can choose from the predefined list of locations – see a picture example below) or create new one. (OPTIONAL).

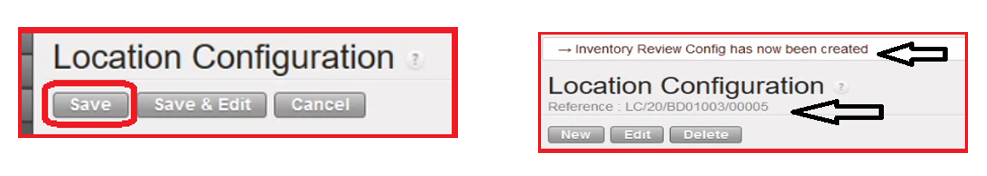

7. Click on “Save” and see the message “Inventory Review Config has now been created” which is the next configuration step