Supply User Manual ENG -> 5. Warehouse -> 5.3 LU-SU4102: Picking -> I. HOW TO CANCEL A PICKING

I. HOW TO CANCEL A PICKING

Sometimes picking documents have to be cancelled. This may happen if you decide to not ship the back-orders or if the requesting project does not need the goods anymore. Cancellation may be done on a main PICK or a sub PICK. Cancellation on main PICK can be done at header or line level while cancellation on sub PICK can only be done at header level.

A cancellation on a main PICK will directly impact the related FO ( and Cancel/Close it/ or its lines) while a cancellation on a sub PICK will simply cancel the sub PICK and resend line items from the sub PICK to the main PICK.

In case of cancellation on a PICK related to a Loan FO, the related counterpart Loan PO document/line will also be Cancelled (see Procurement chapter on FO and PO Loan).

Pick Cancellation often results on products being sent to “Cross Docking” location when products have been sourced to a PO from an FO. In order to avoid this, at Cancellation user now have the option to send the goods either to Cross Docking or to proceed to an INTernal Move (automatically created).

1) Cancellation on main PICK at header level (with FO sourced on order)

Go to: Warehouse / Warehouse Management / Deliveries / Picking

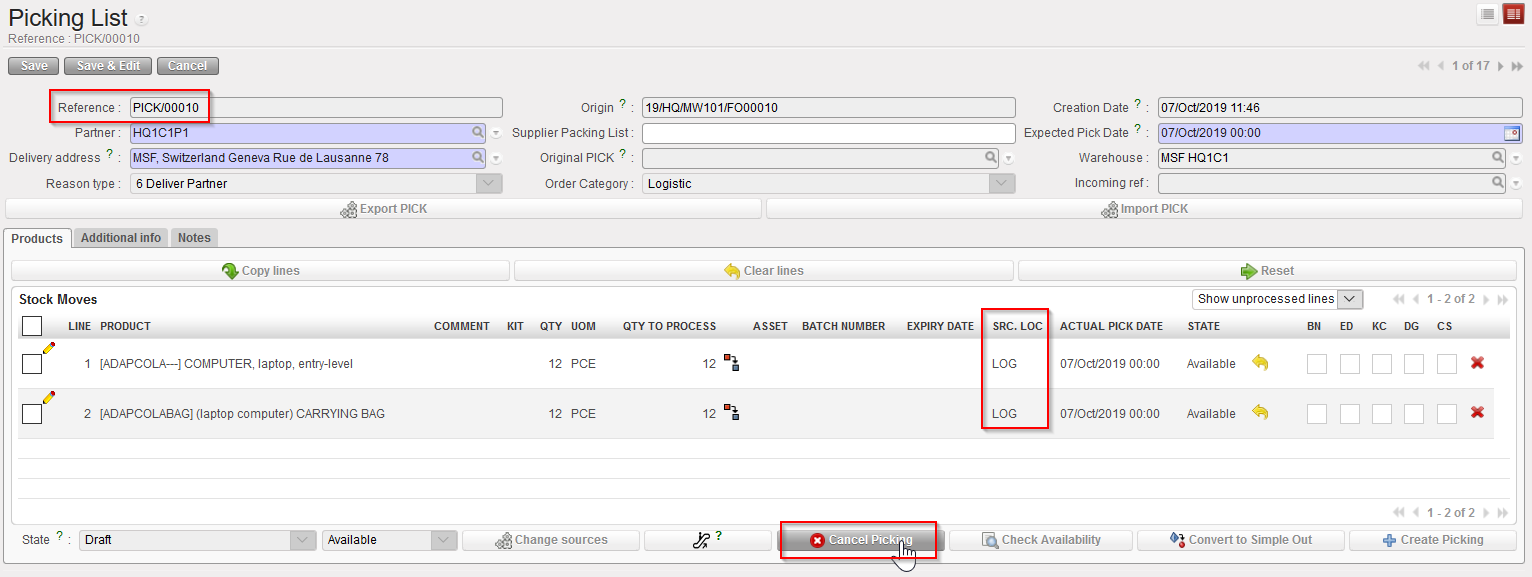

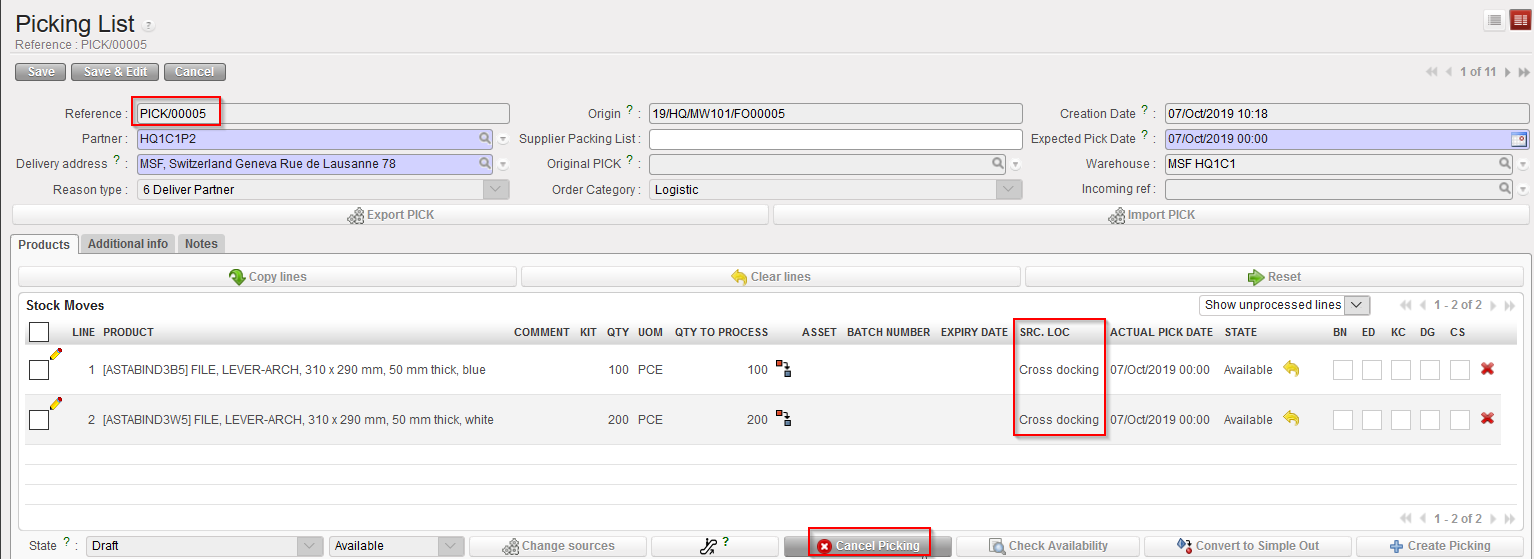

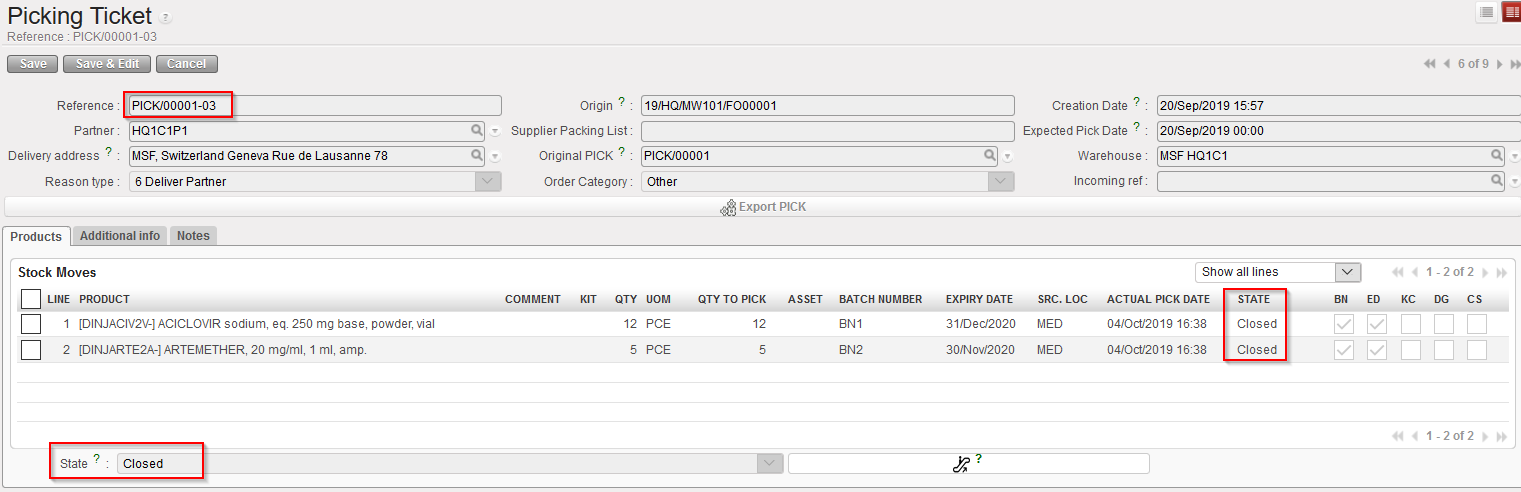

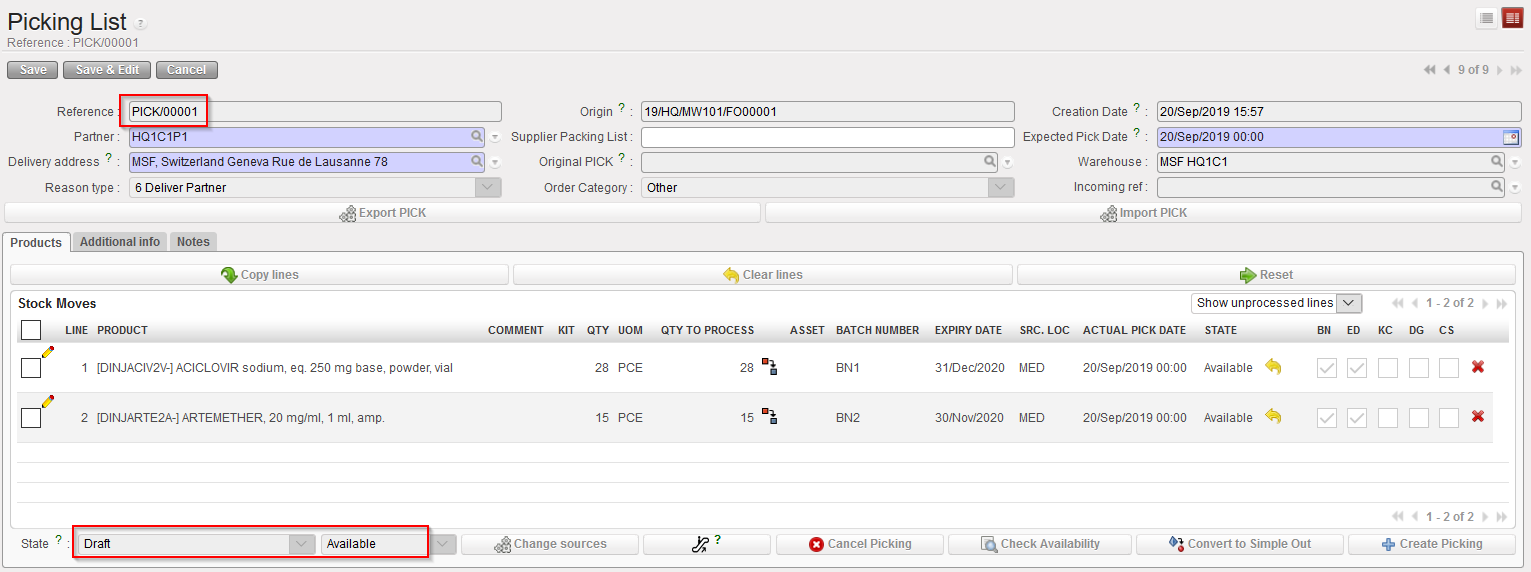

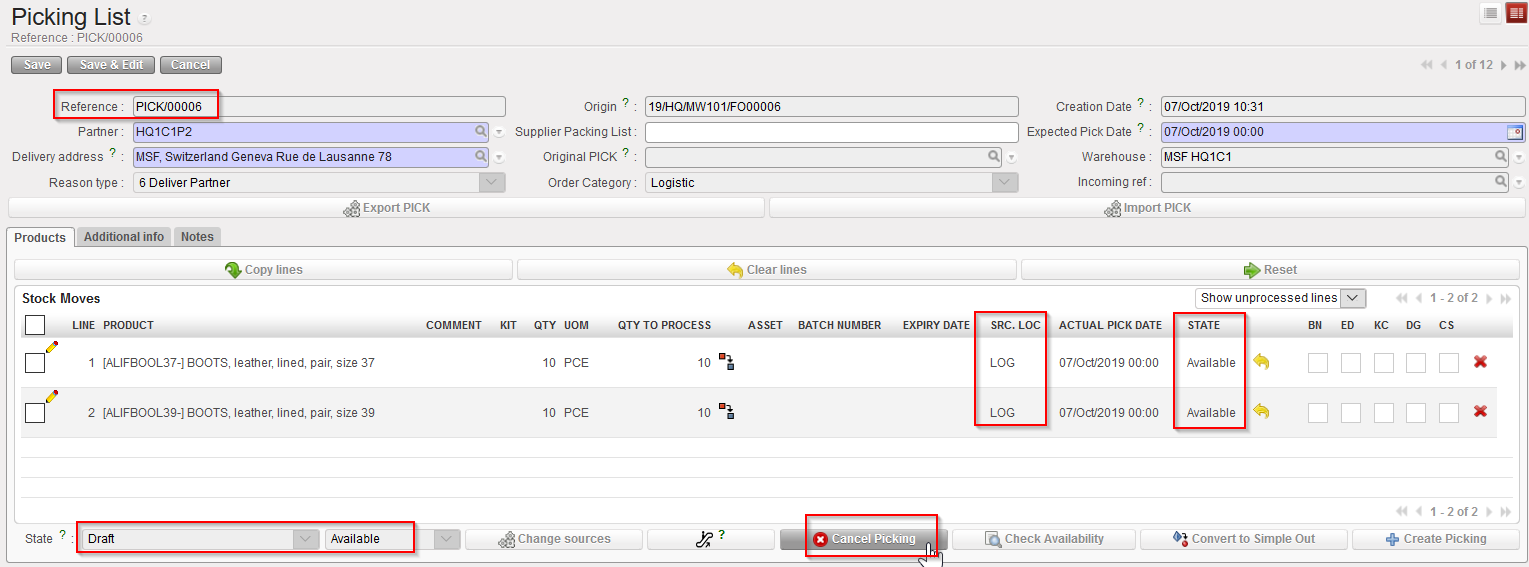

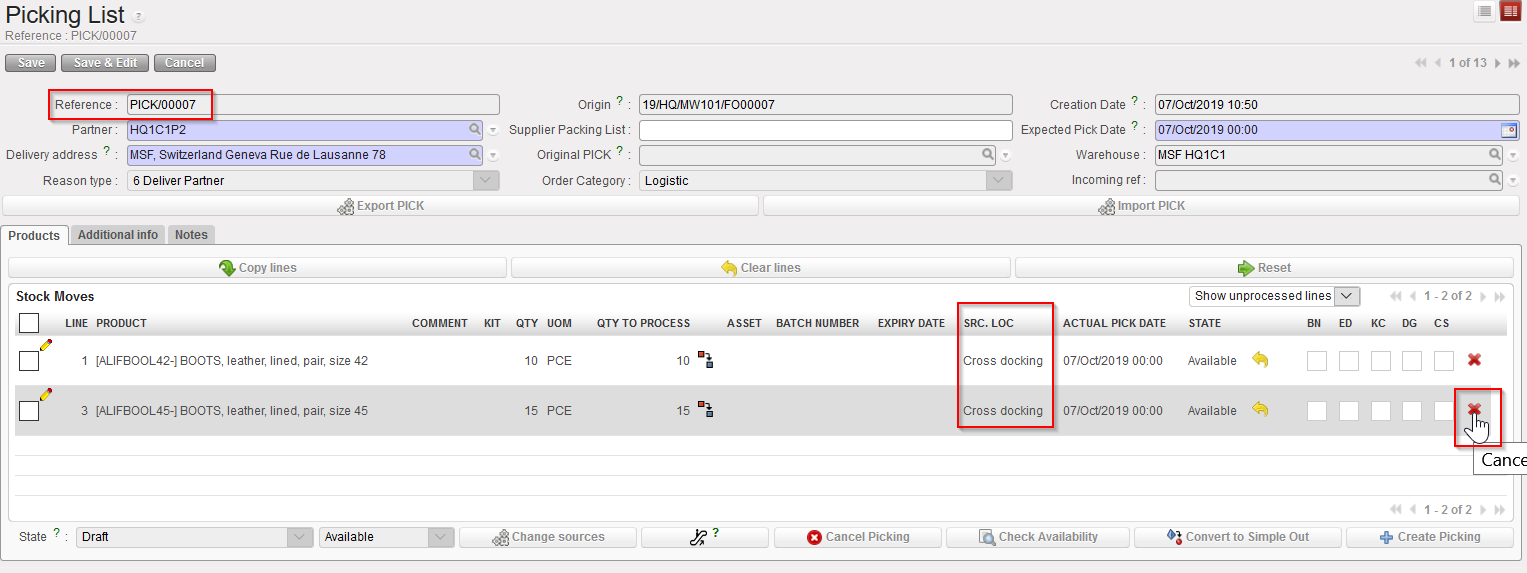

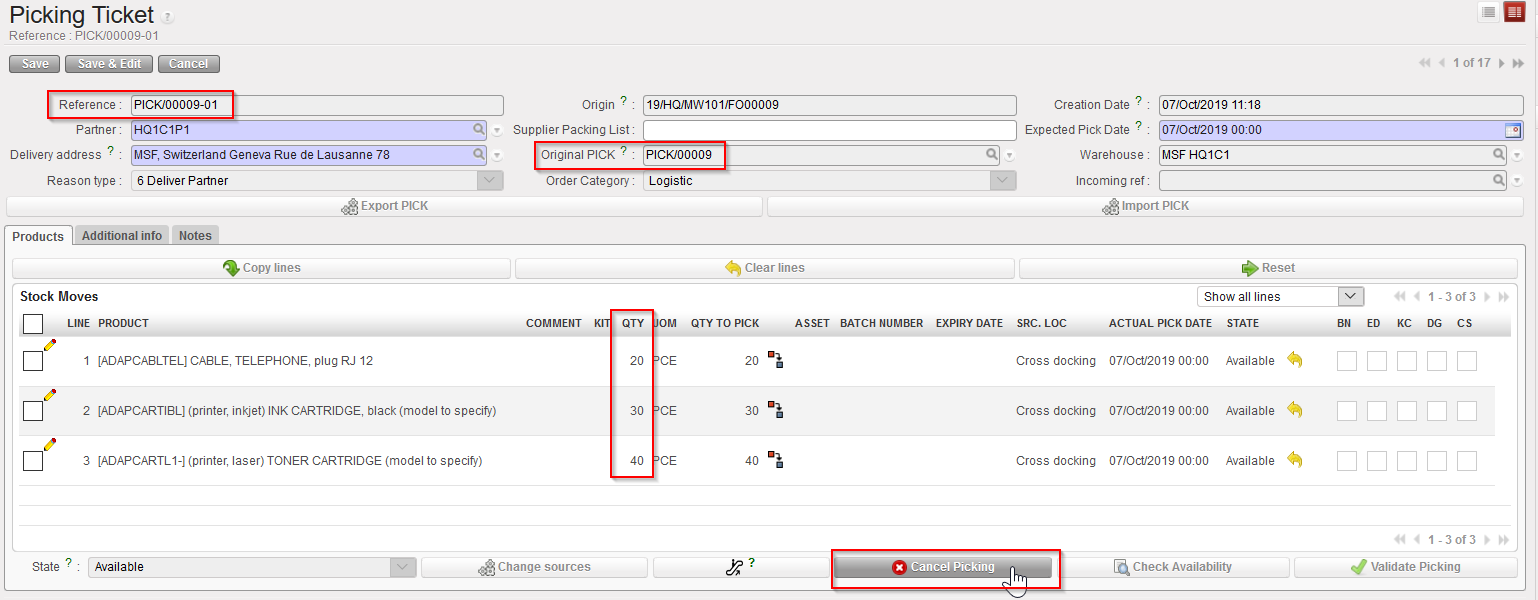

- Open the Picking Ticket you wish to cancel (main PICK in this case)

- Click on the “Cancel Picking” button located at the bottom of the screen.

|

|

|

Cancelling a main PICK at header level

|

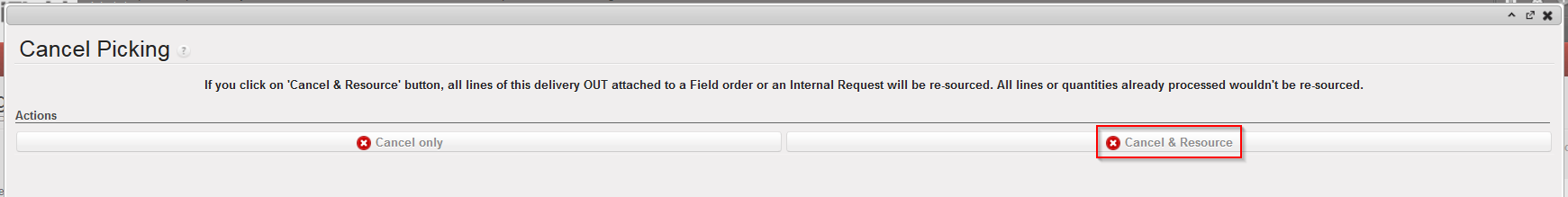

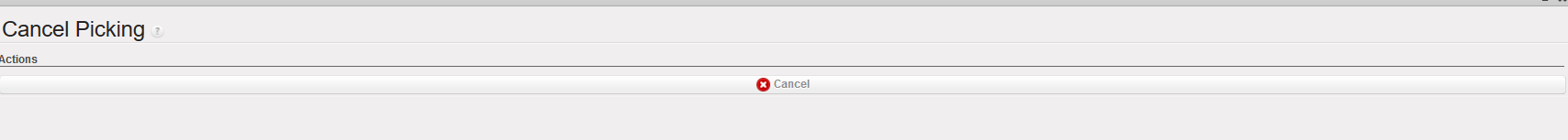

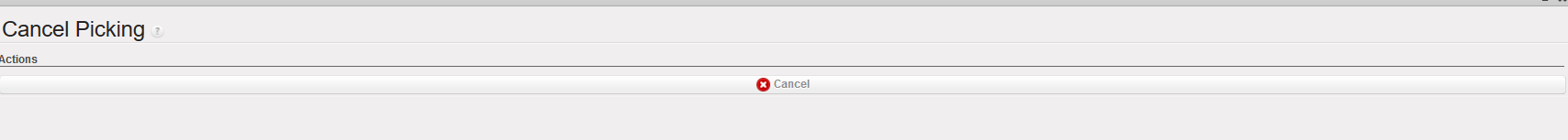

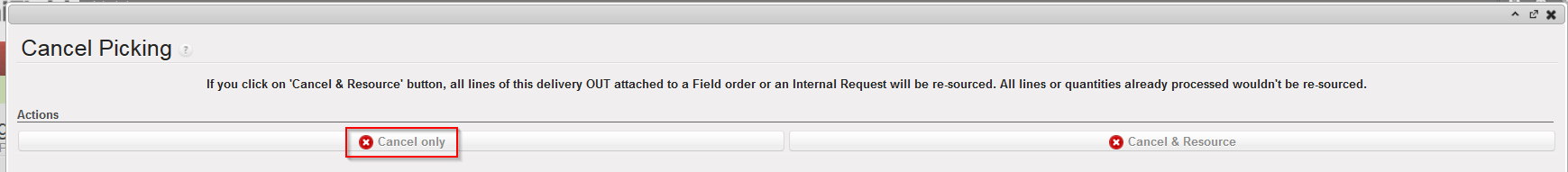

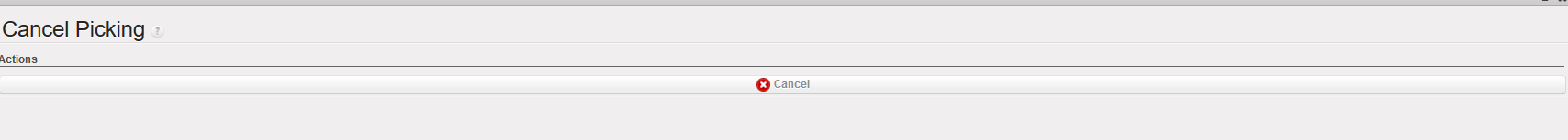

3. Confirm the cancellation in the “Cancel Picking” window by clicking on the “Cancel” button.

|

|

|

Confirming cancellation of a main PICK at header level

|

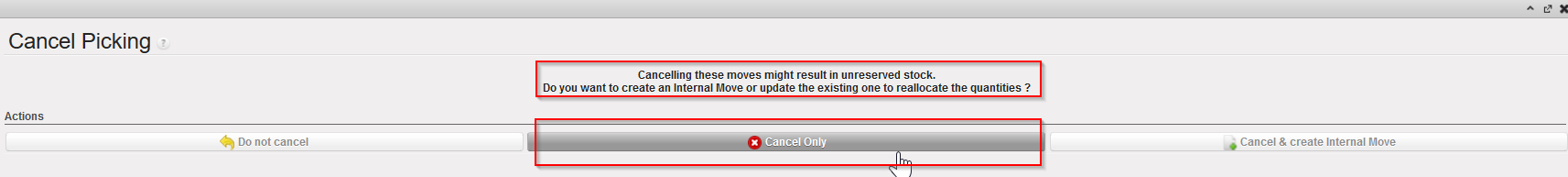

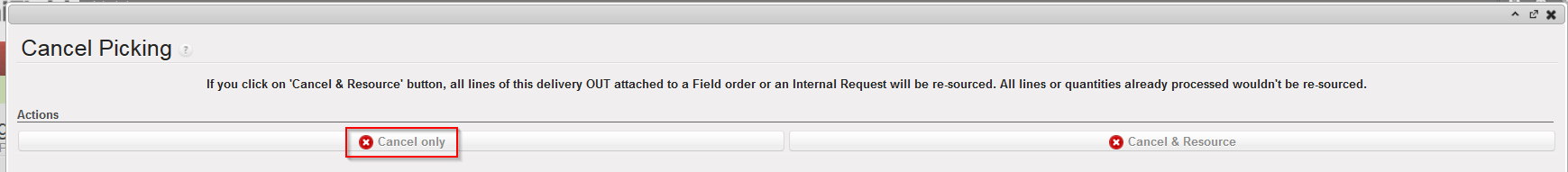

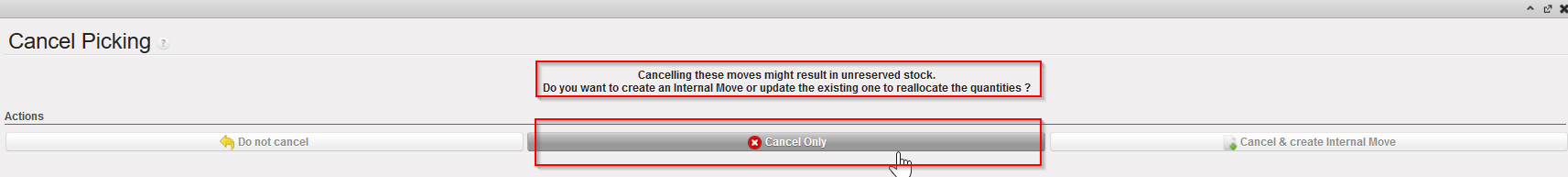

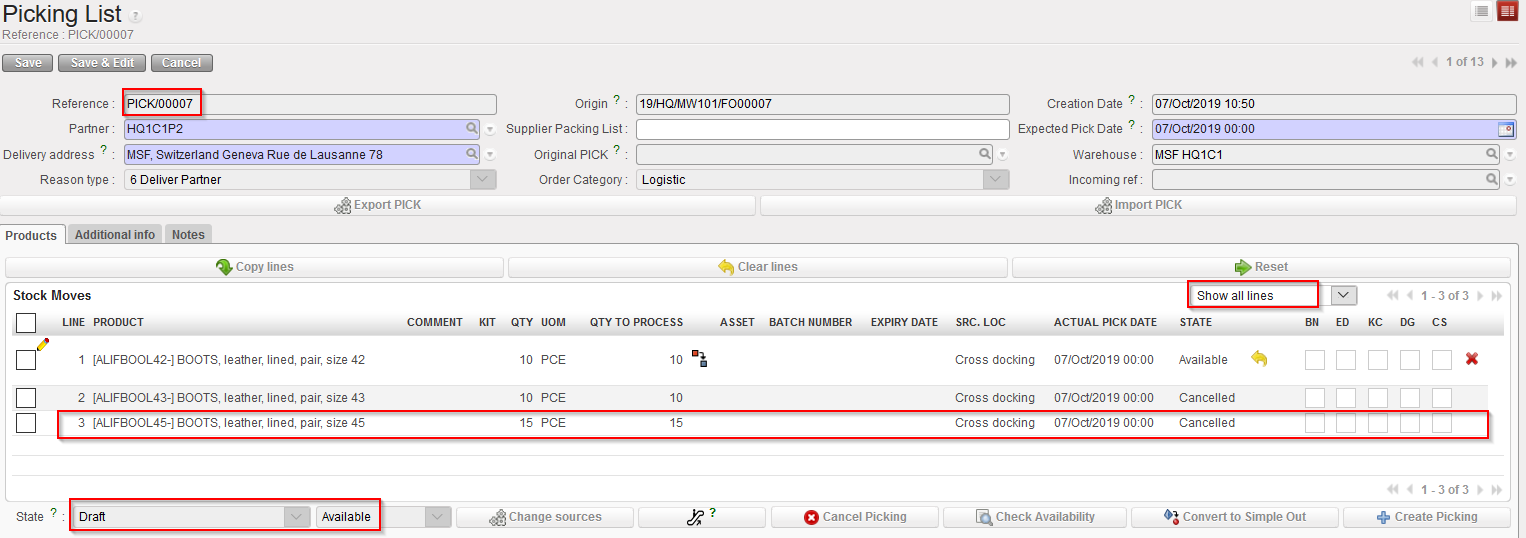

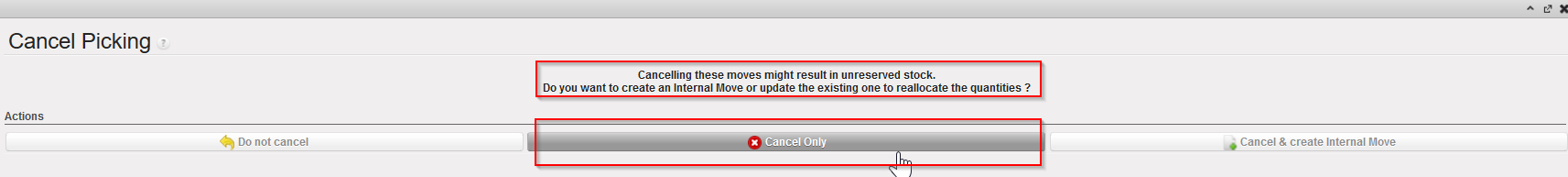

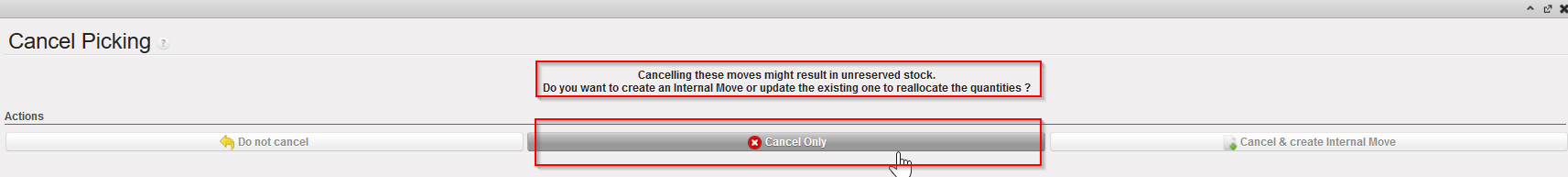

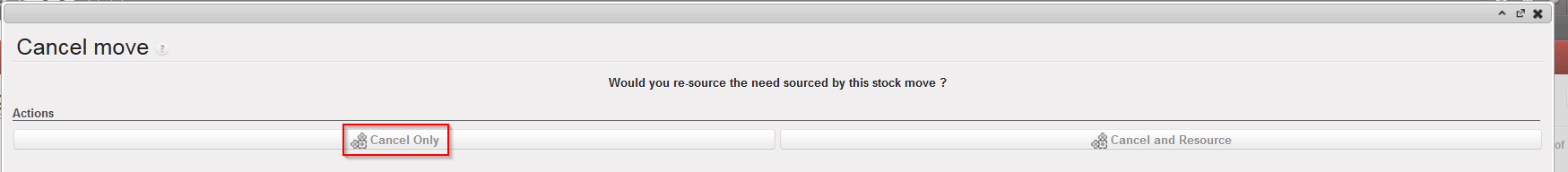

4. Select what needs to be done with the Cancelled products

a) Click on “Cancel Only” to send the goods to cross docking anyway (will be unreserved products)

|

|

|

Click on “Cancel only” to proceed anyway to product sent to Cross Docking

|

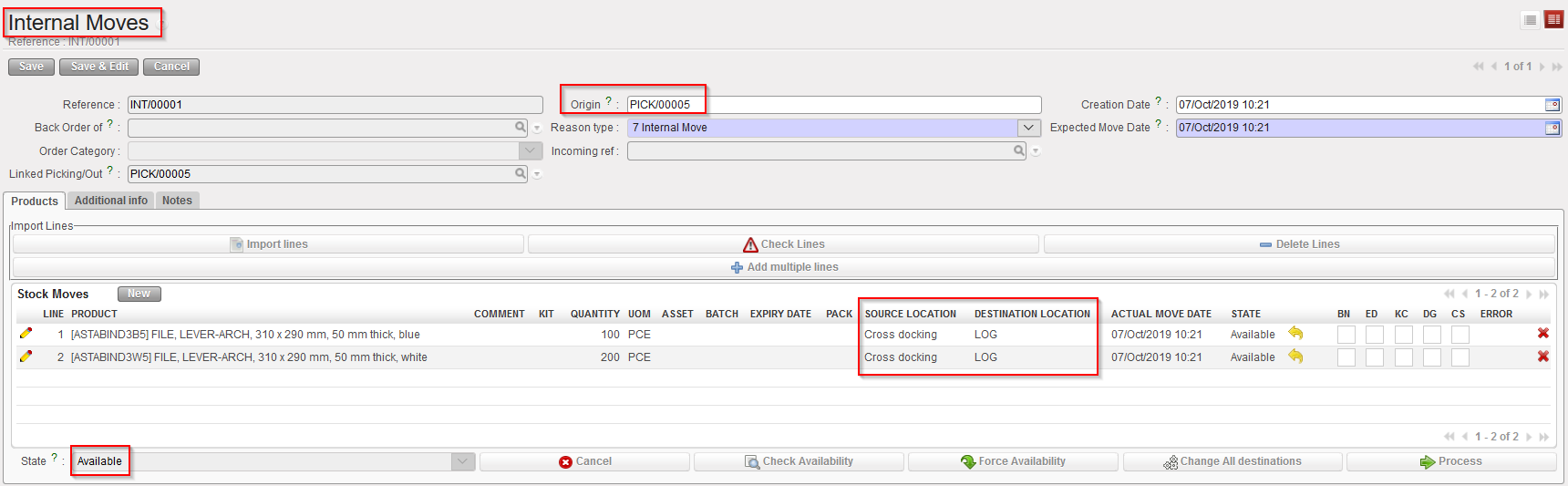

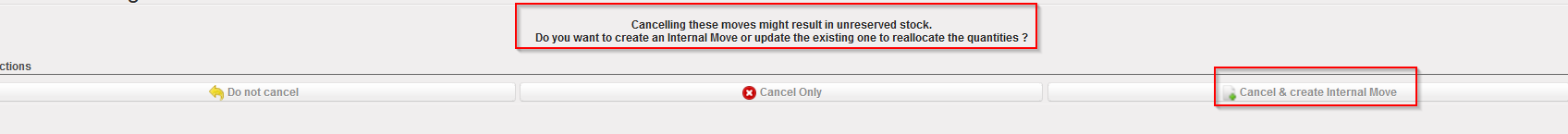

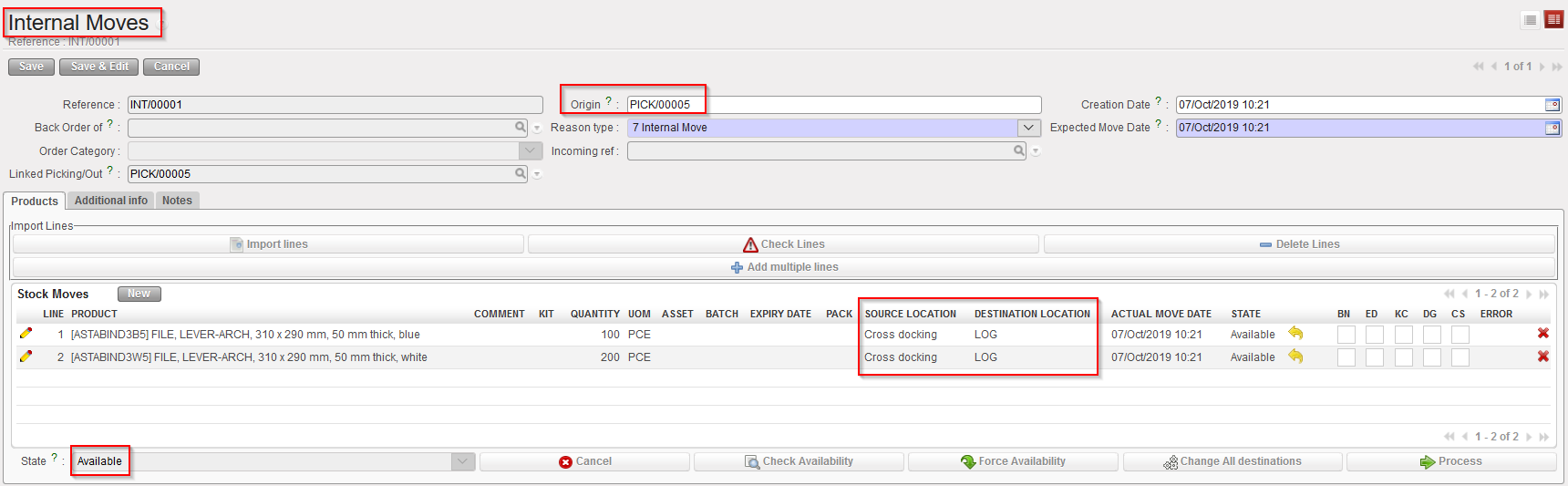

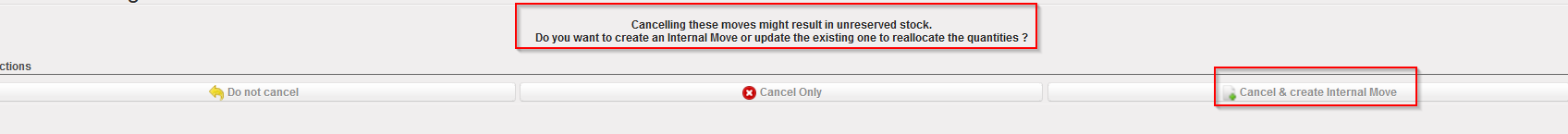

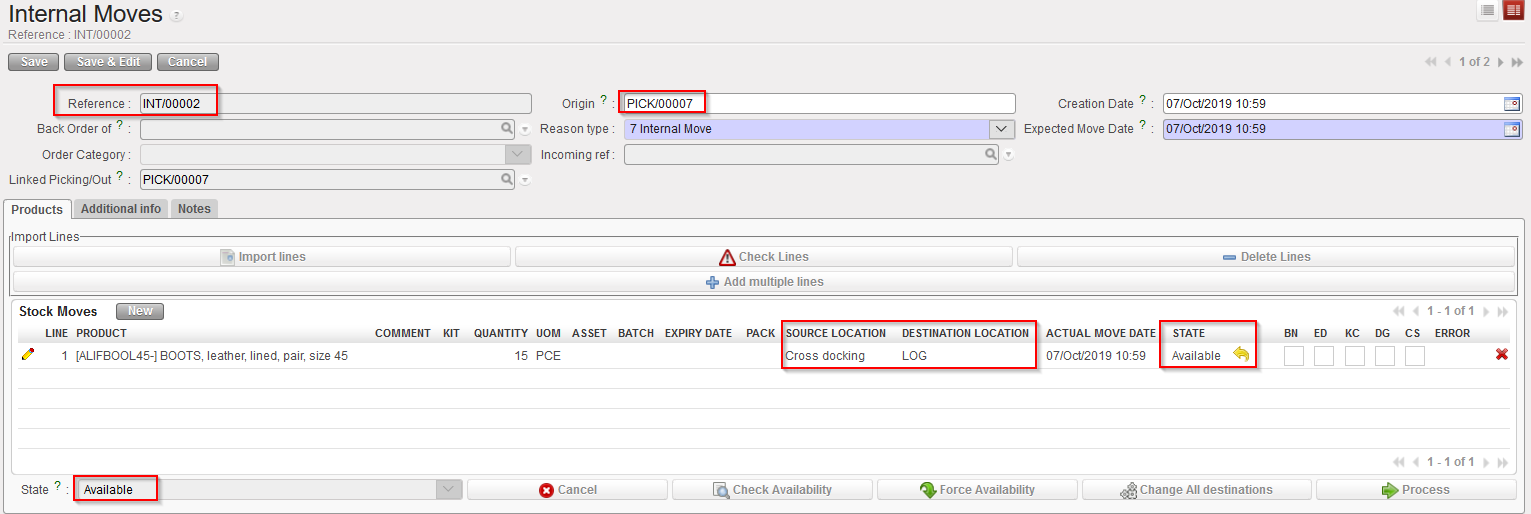

b) Click on “Cancel & create Internal Move” to generate the creation of a new “Available” INT with “Source location” = Cross Docking and “Destination location” = MED/LOG depending on type of products

|

|

|

New INT created following main PICK Cancellation

|

Please refer to the chapter “LU-SU4201 INTERNAL MOVES” to proceed forward with this INT.

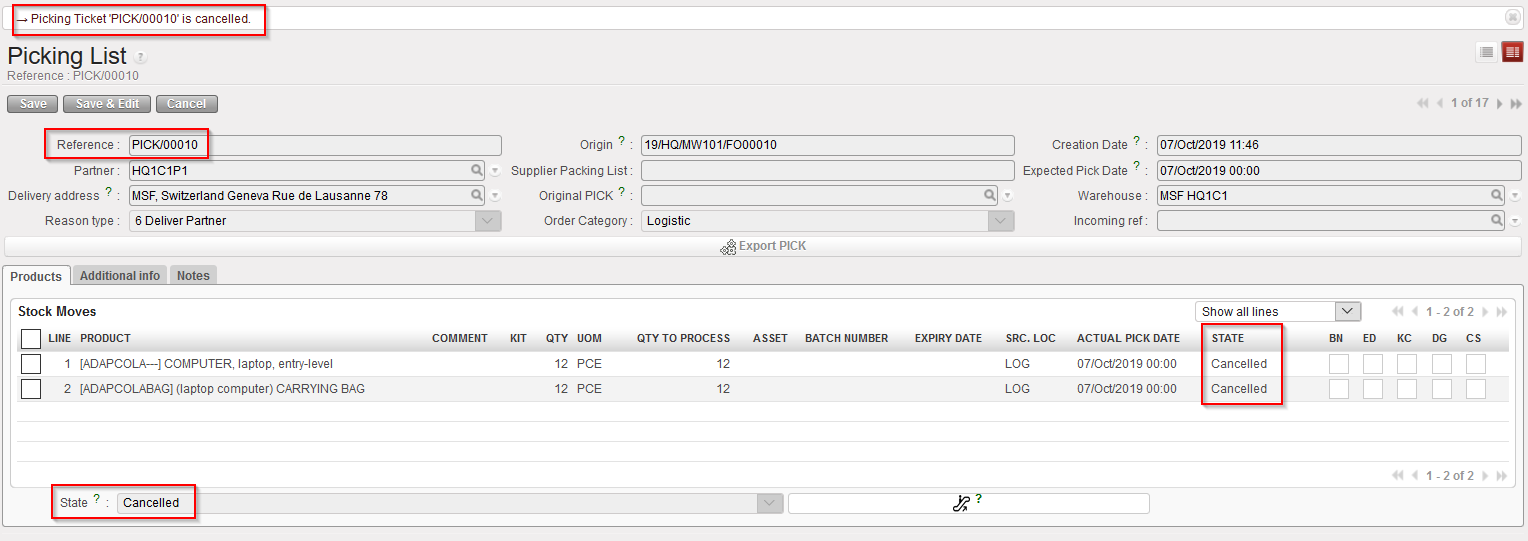

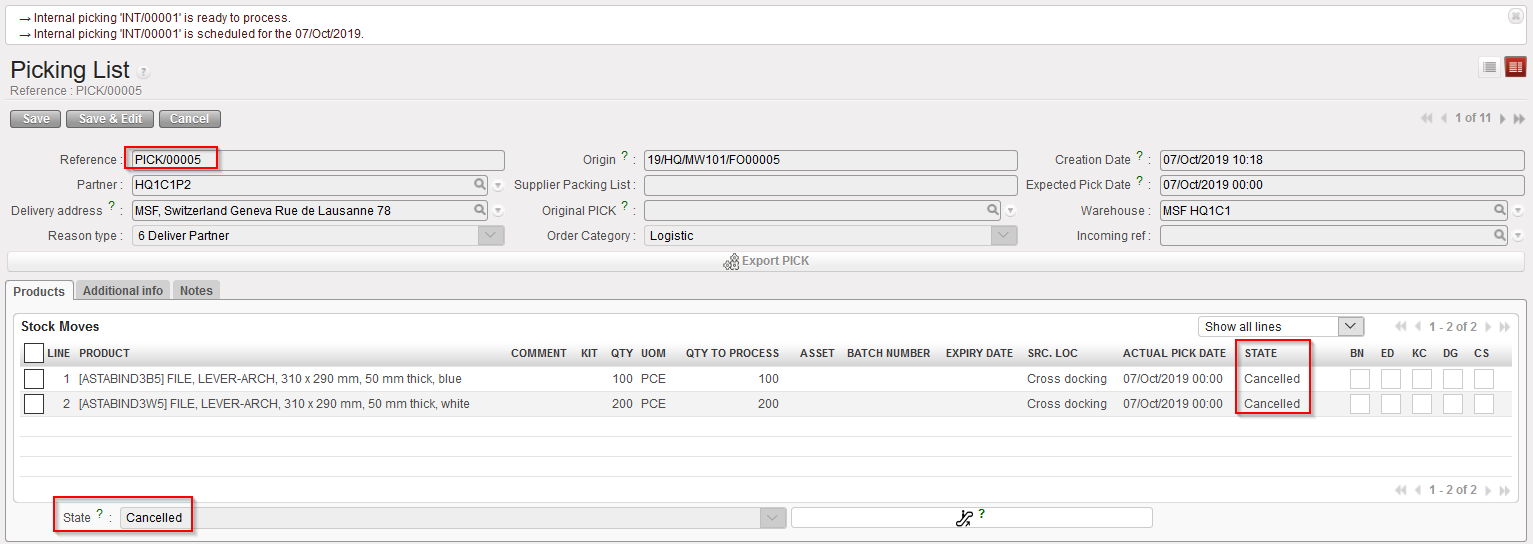

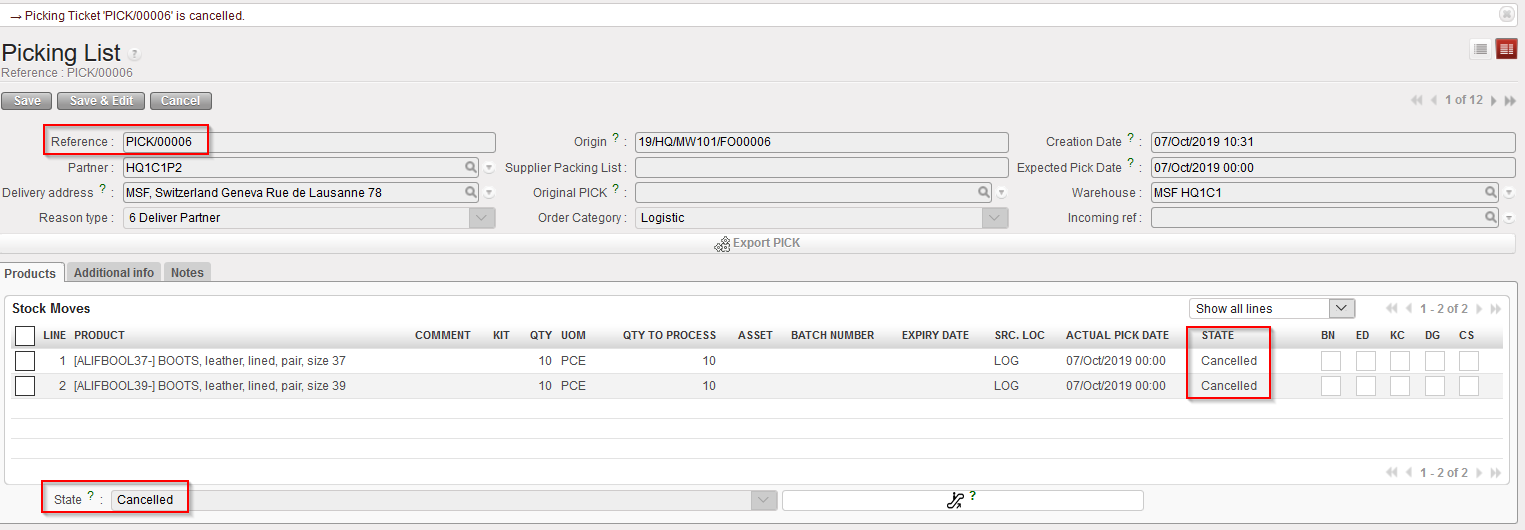

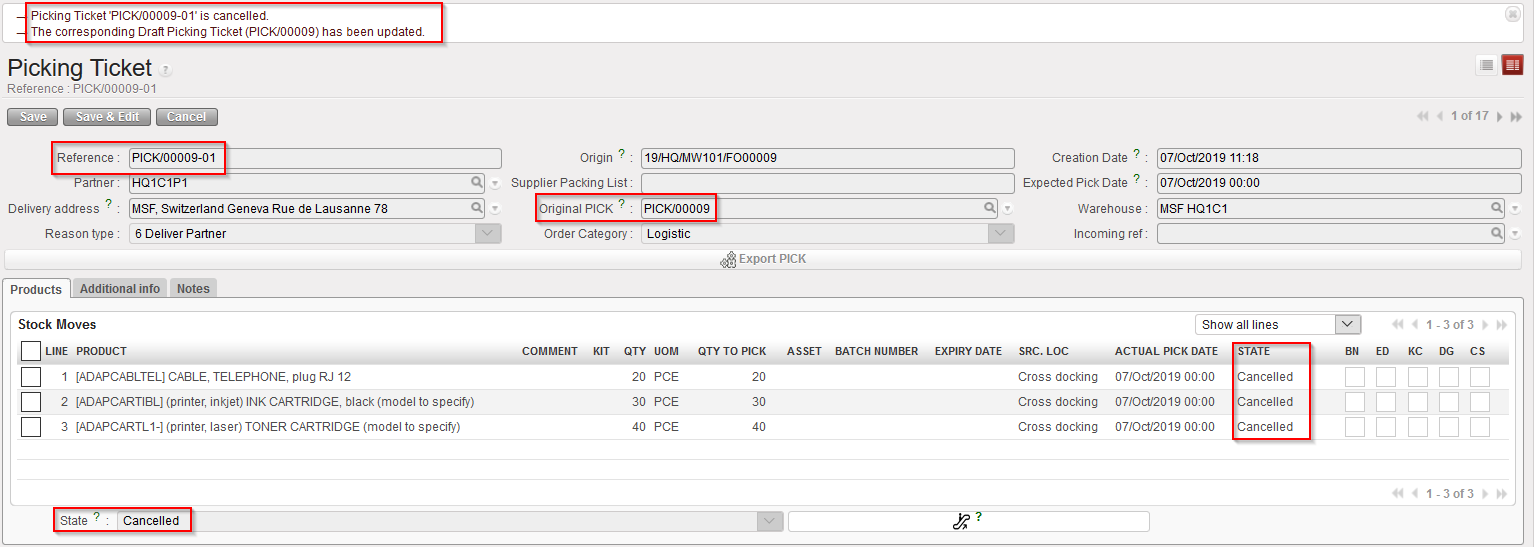

In both cases, the PICK will display the same result: it will be Cancelled

|

|

|

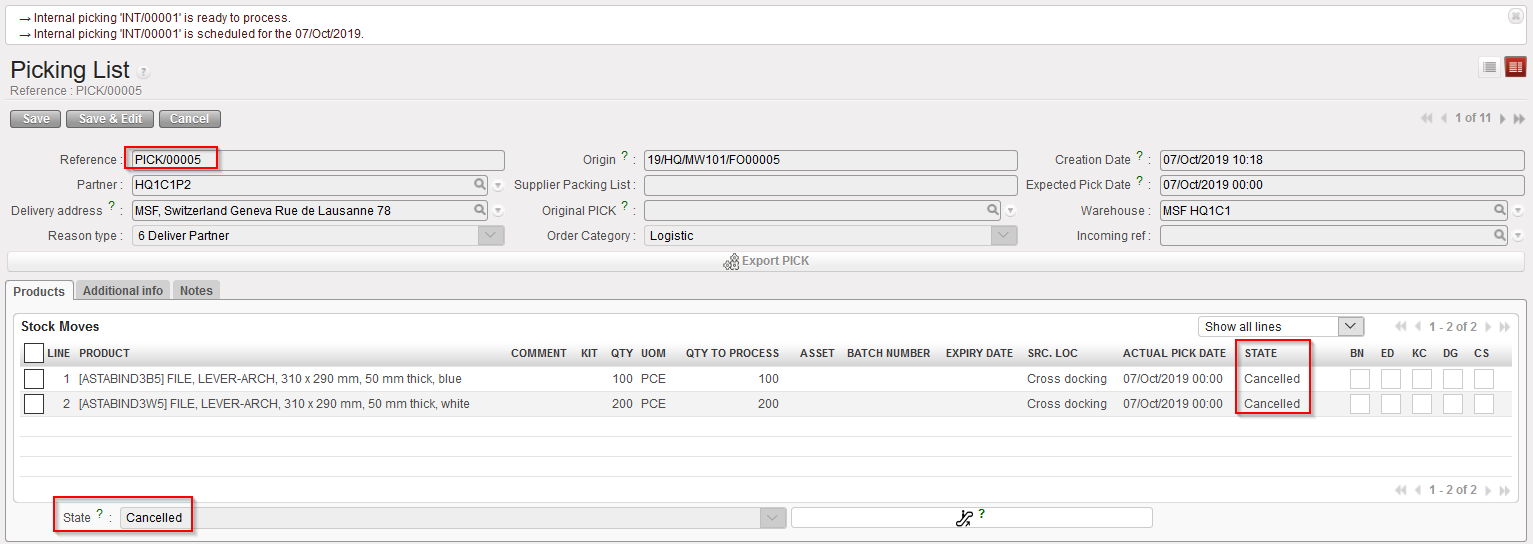

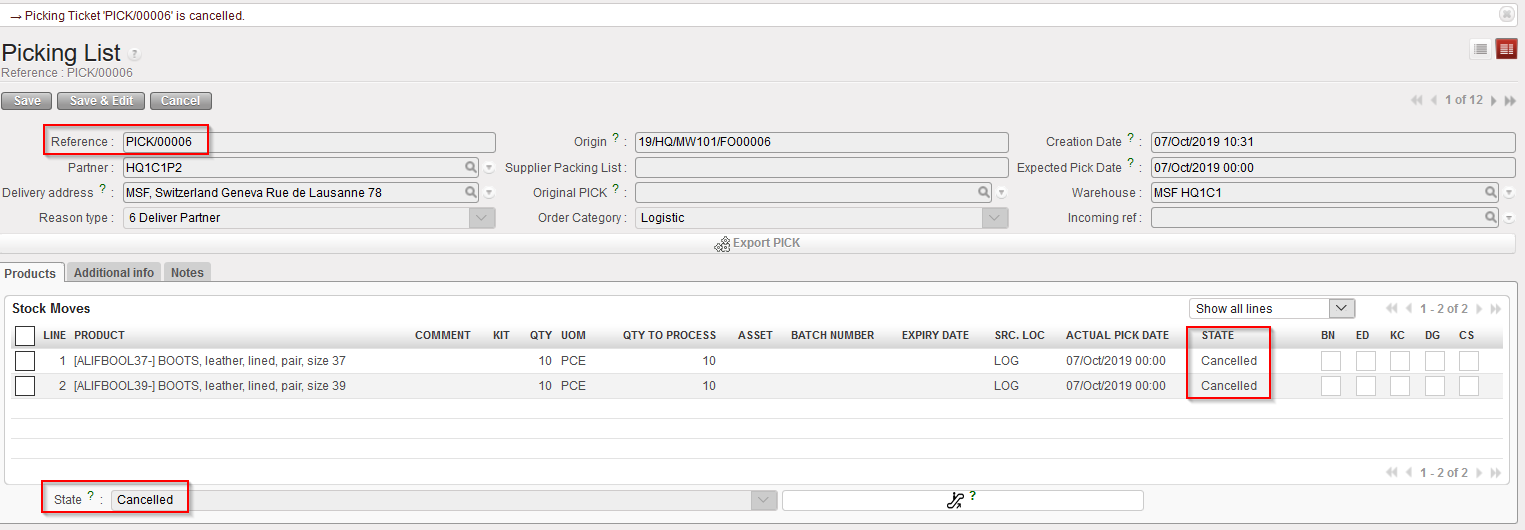

Main PICK cancelled at header level

|

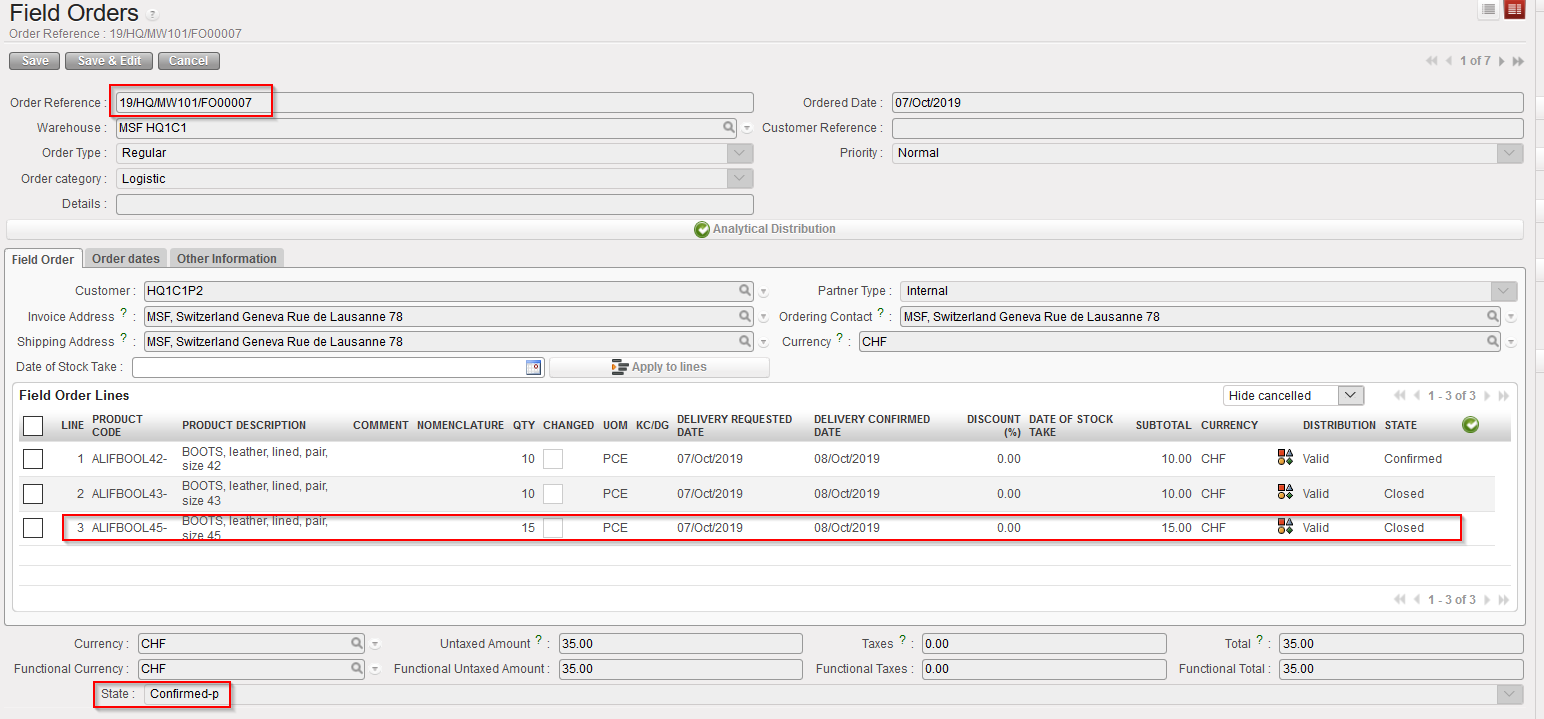

The state of the Picking Ticket (and of all its lines) switches to “Cancelled“.

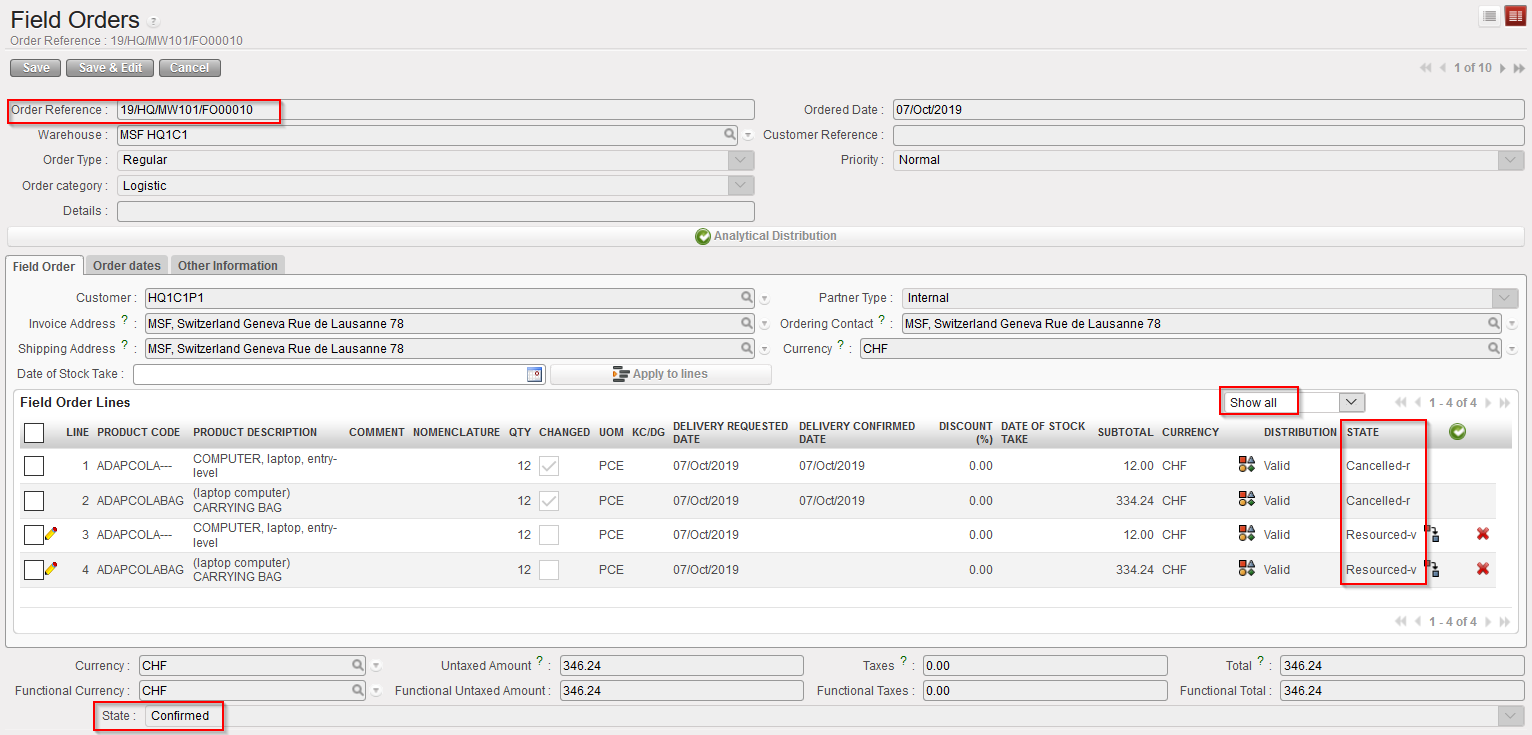

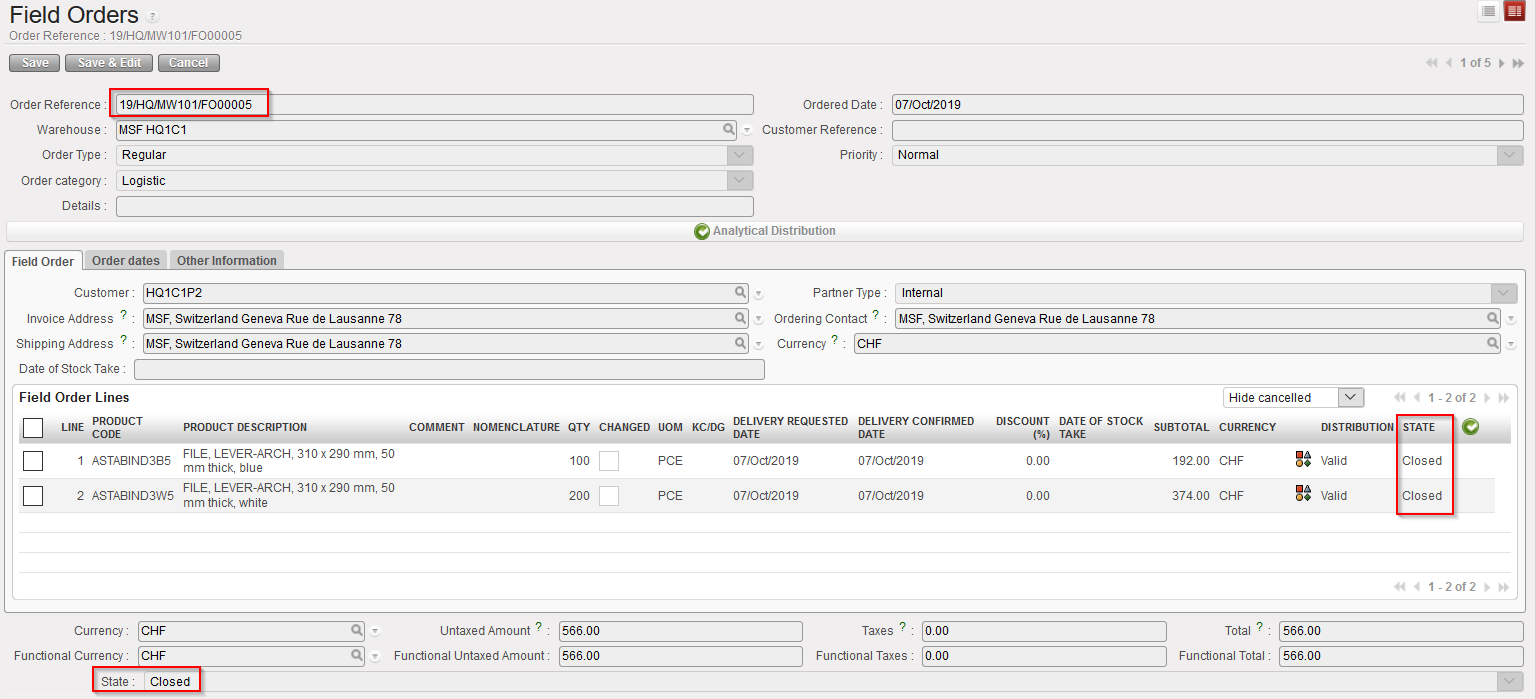

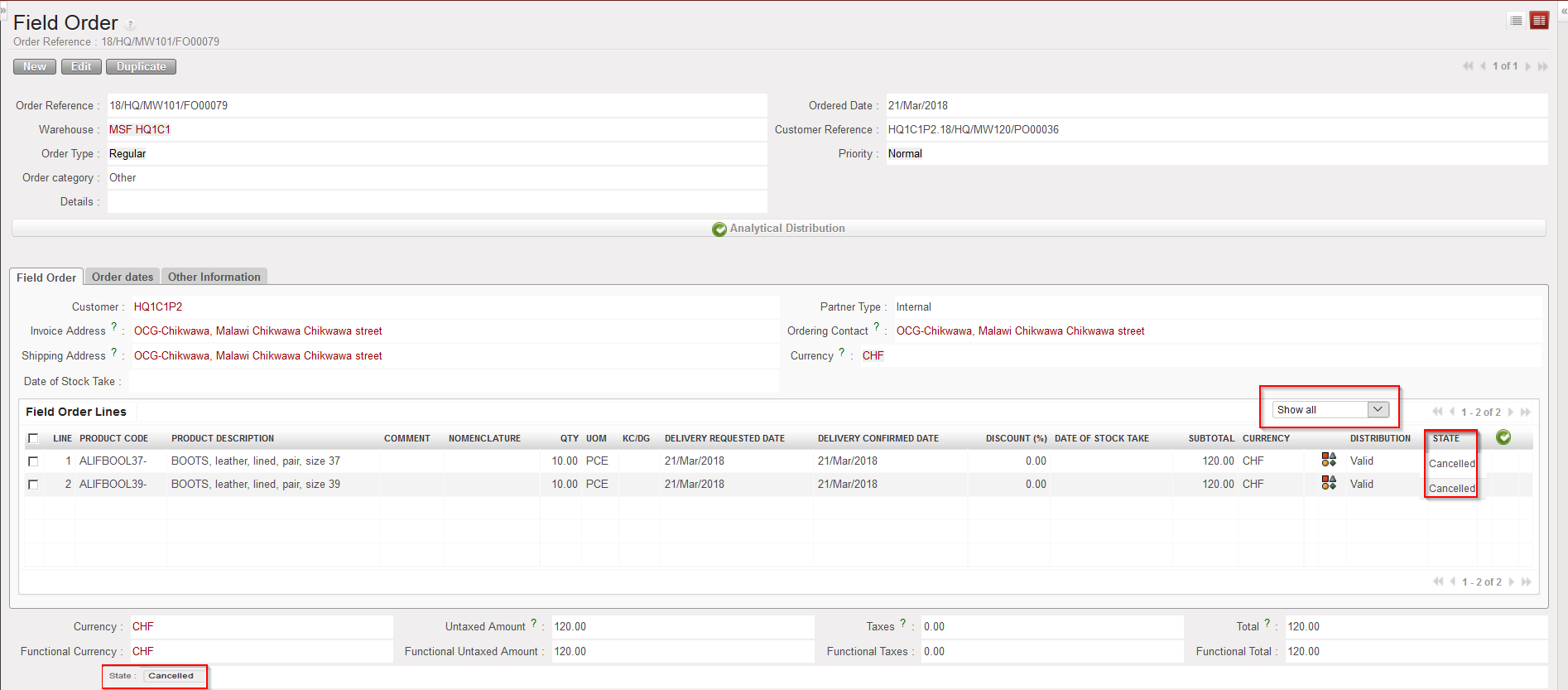

Note that this will also trigger the Closing of the related FO with all FO-lines “Closed” (see below – please note that lines are closed because sourcing was done from PO; had it been done from Stock, lines would have been Cancelled).

|

|

|

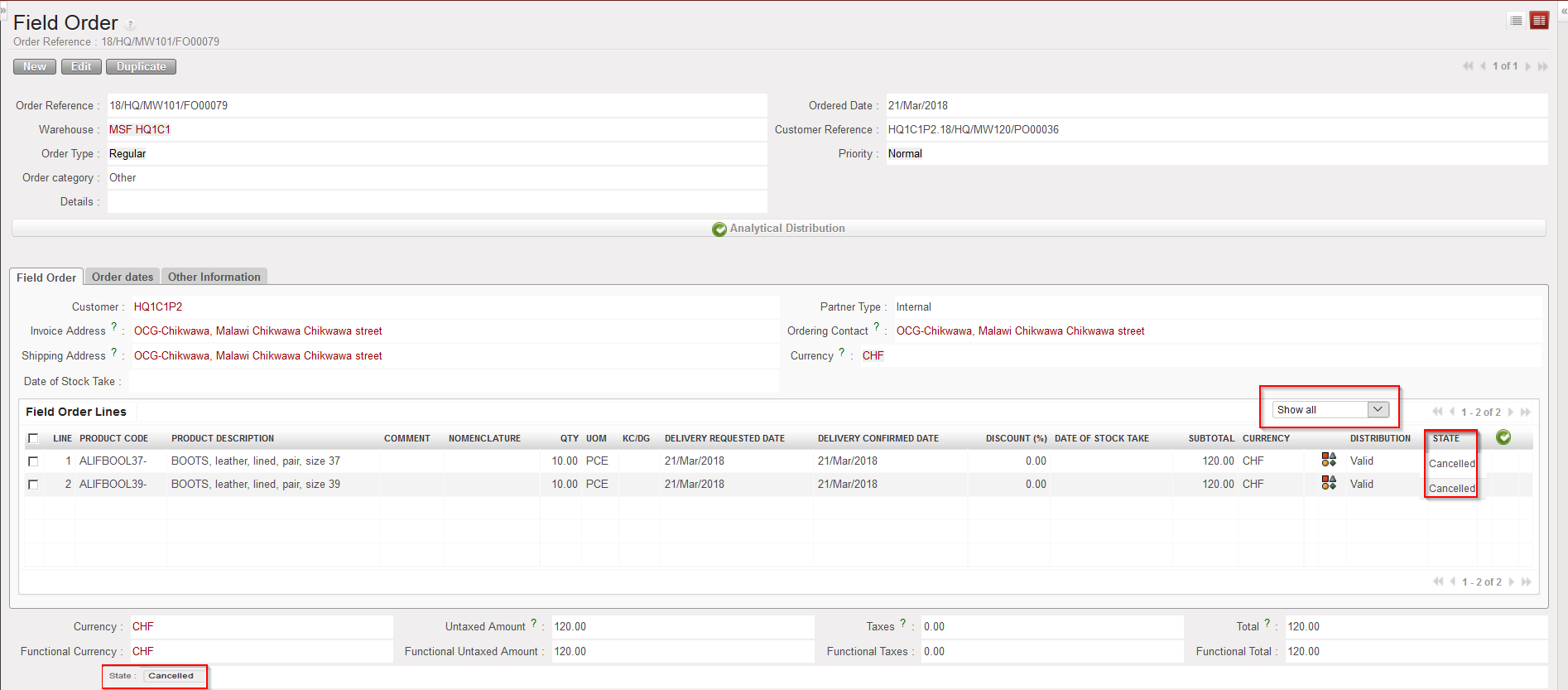

FO Closed following cancellation of a main PICK at header level

|

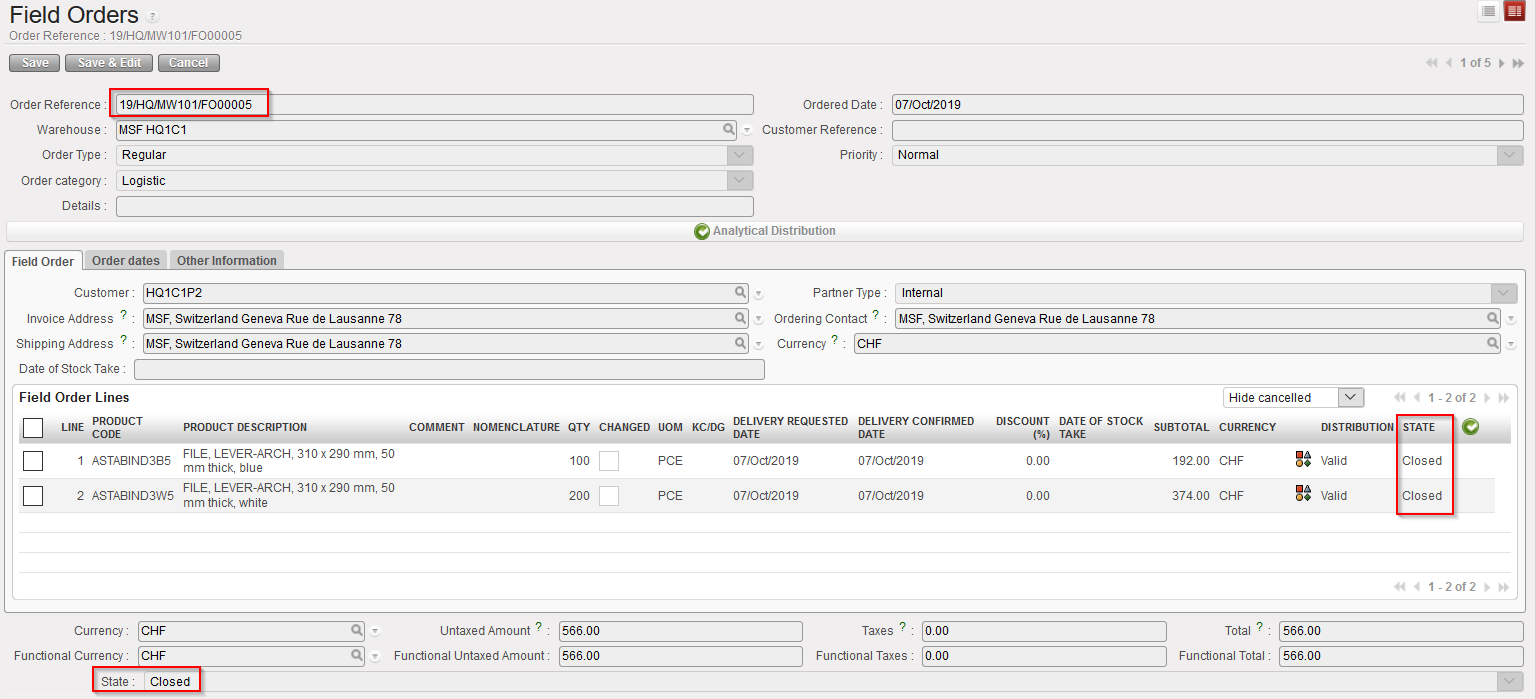

2) Cancellation on main PICK at header level (with FO sourced from stock)

Go to: Warehouse / Warehouse Management / Deliveries / Picking

- Open the Picking Ticket you wish to cancel (main PICK in this case)

- Click on the “Cancel Picking” button located at the bottom of the screen.

|

|

|

Cancelling a main PICK at header level

|

3. Confirm the cancellation in the “Cancel Picking” window by clicking on the “Cancel only” button.

|

|

|

Confirming cancellation of a main PICK at header level

|

|

|

|

Main PICK cancelled at header level

|

The state of the Picking Ticket (and of all its lines) switches to “Cancelled“.

As a consequence, the corresponding FO (and all its lines) switches to the state “Cancelled” (see below – please note that lines are Cancelled (not Closed) because sourcing has been done from Stock).

|

|

|

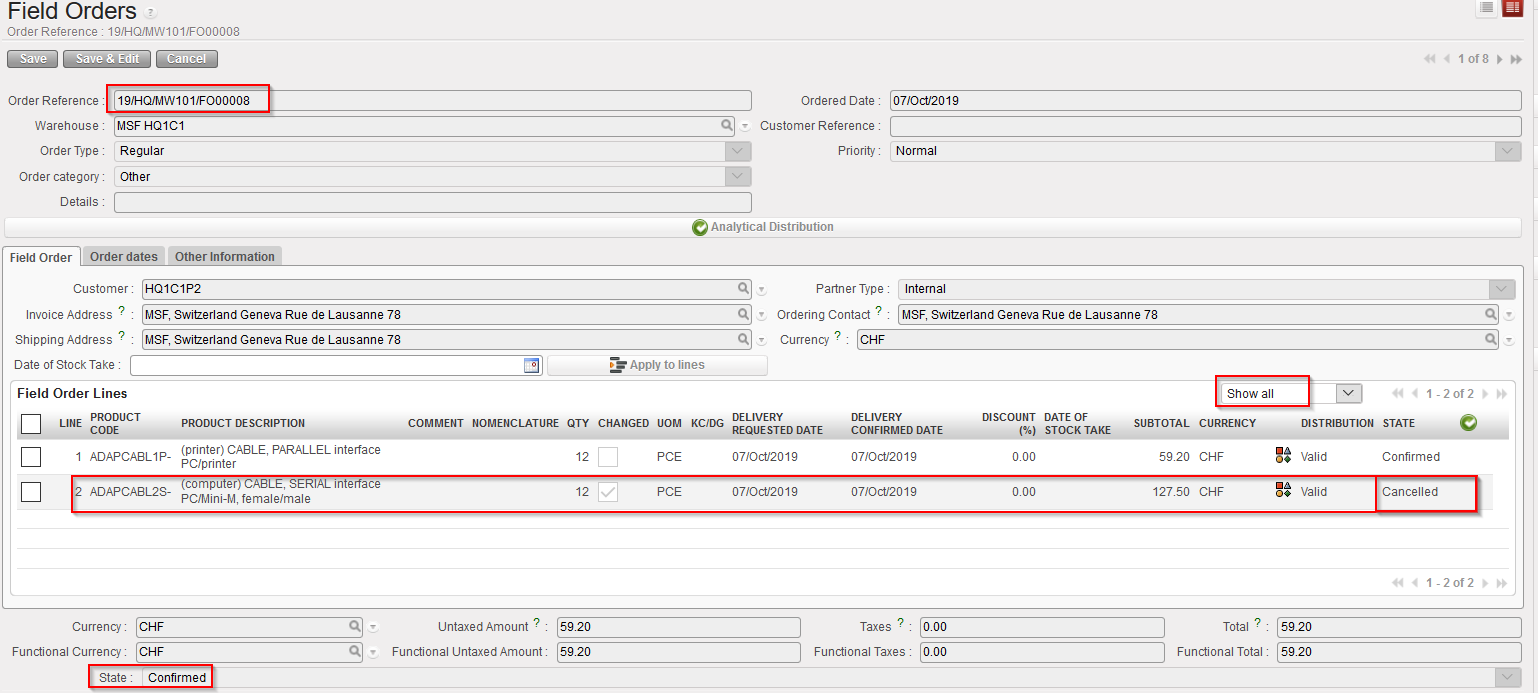

FO Cancelled following cancellation of a main PICK at header level (note that “Show all filter” is on)

|

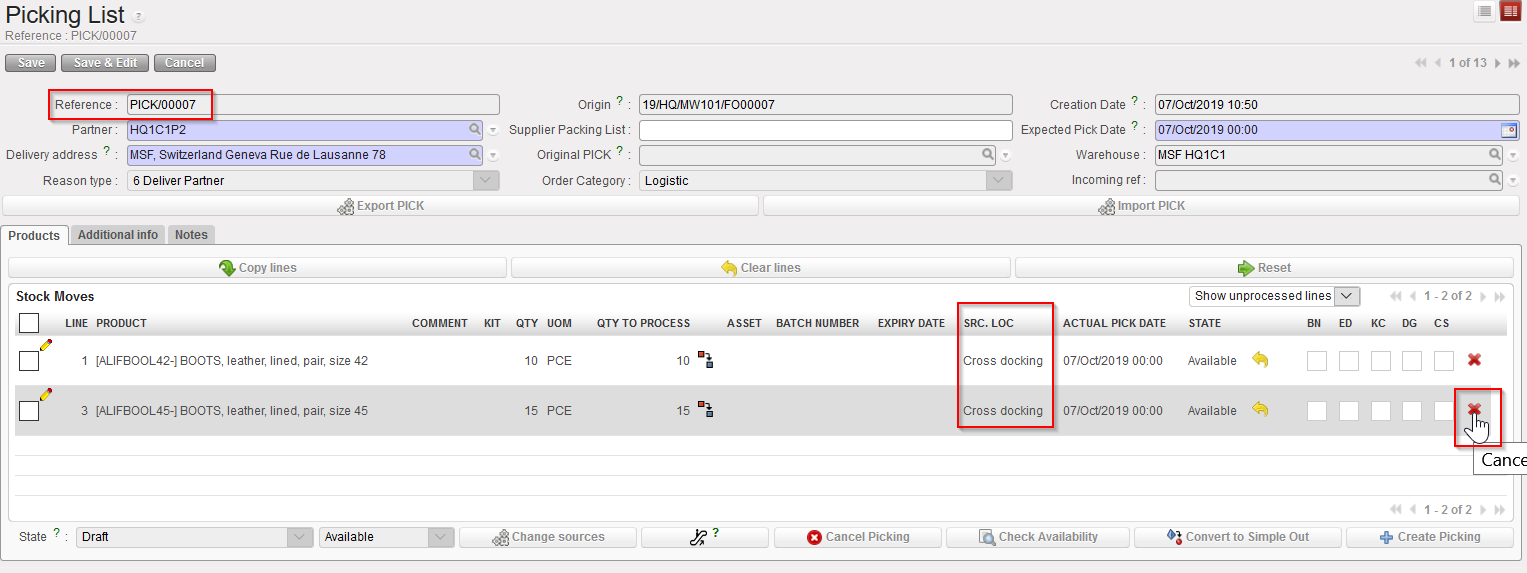

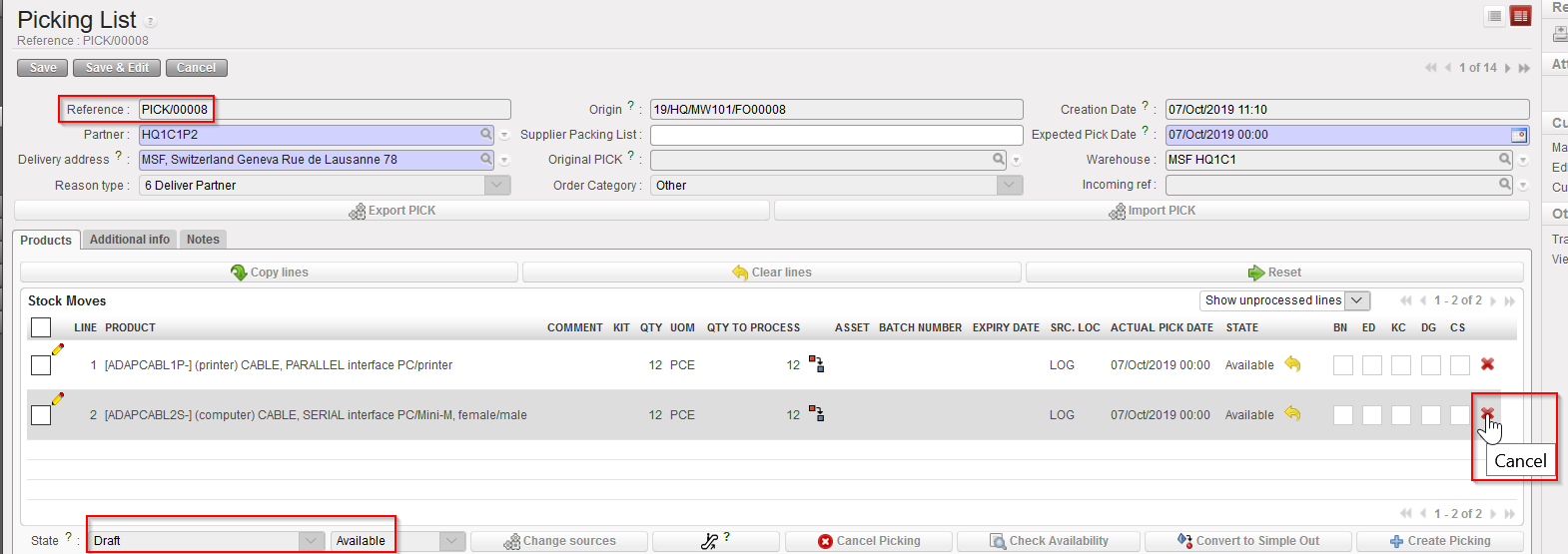

3) Cancellation on main PICK at line level (with FO sourced on order)

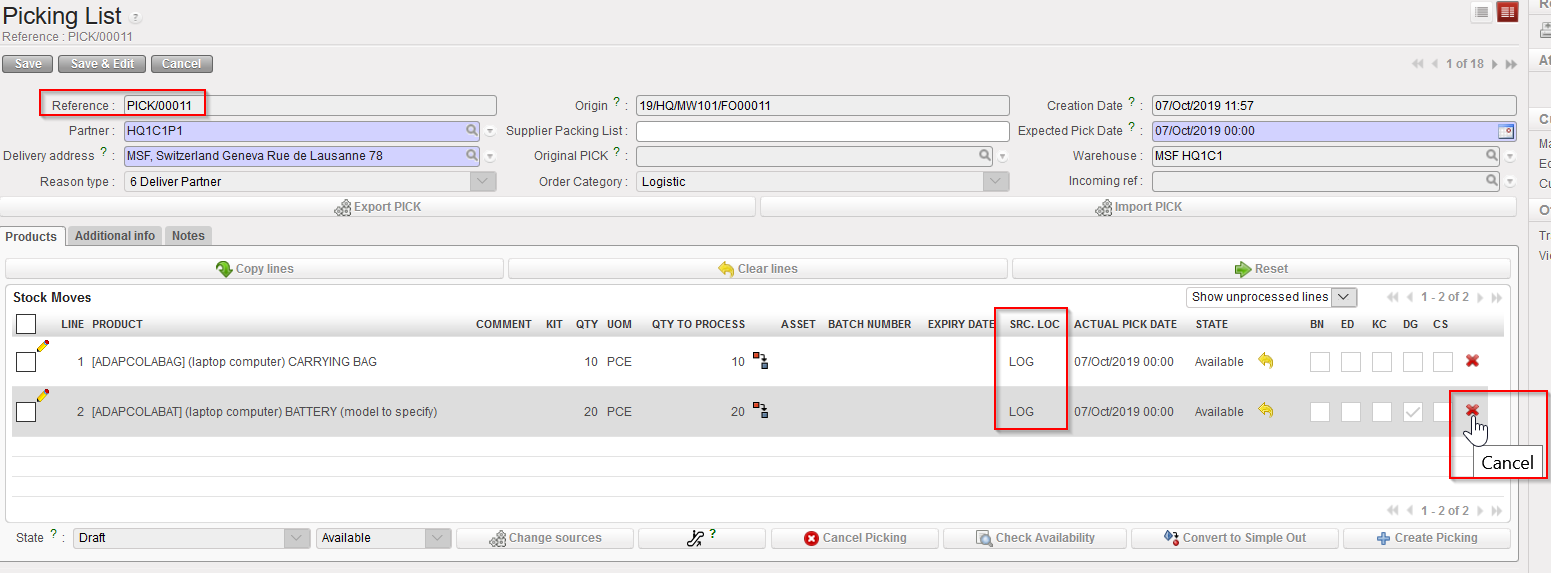

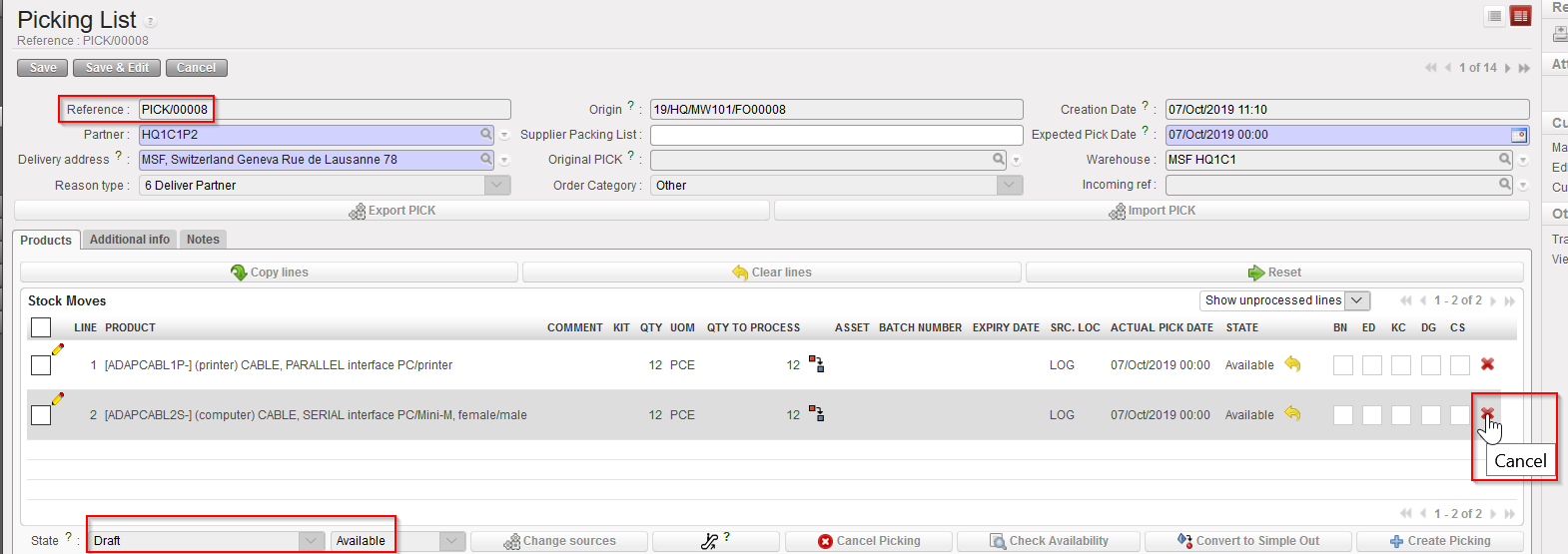

Go to: Warehouse / Warehouse Management / Deliveries / Picking

- Open the Picking Ticket on which you wish to cancel a line (main PICK in this case)

- Click on the red cross located at the right of the line you wish to cancel

|

|

|

Cancelling a line of a main PICK

|

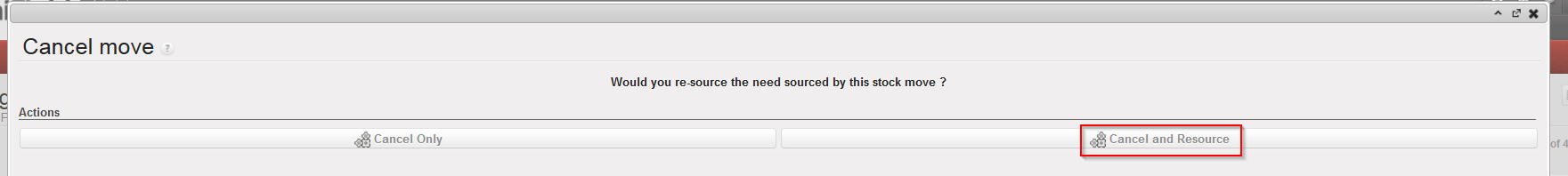

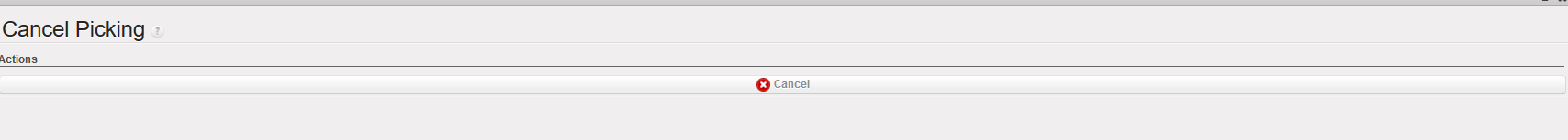

3. Confirm the cancellation in the “Cancel Picking” window by clicking on the “Cancel” button.

|

|

|

Confirming cancellation of a PICK at line level

|

4. Select what needs to be done with the Cancelled products

a) Click on “Cancel Only” to send the goods to cross docking anyway (will be unreserved products)

|

|

|

Click on “Cancel only” to proceed anyway to product sent to Cross Docking

|

b) Click on “Cancel & create Internal Move” to generate the creation of a new “Available” INT with “Source location” = Cross Docking and “Destination location” = MED/LOG depending on type of products

|

|

|

Click on “Cancel & create Internal Move” to move the goods via an INT move

|

|

|

New INT created following PICK line Cancellation

|

Please refer to the chapter “LU-SU4201 INTERNAL MOVES” to proceed forward with this INT.

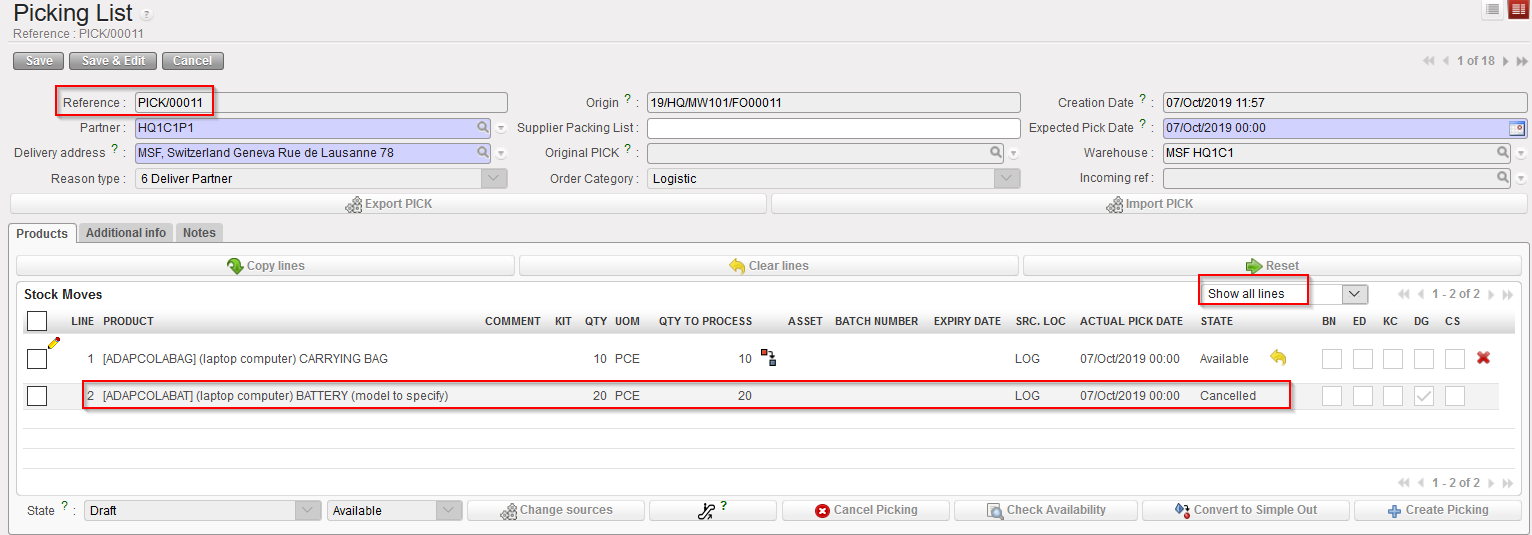

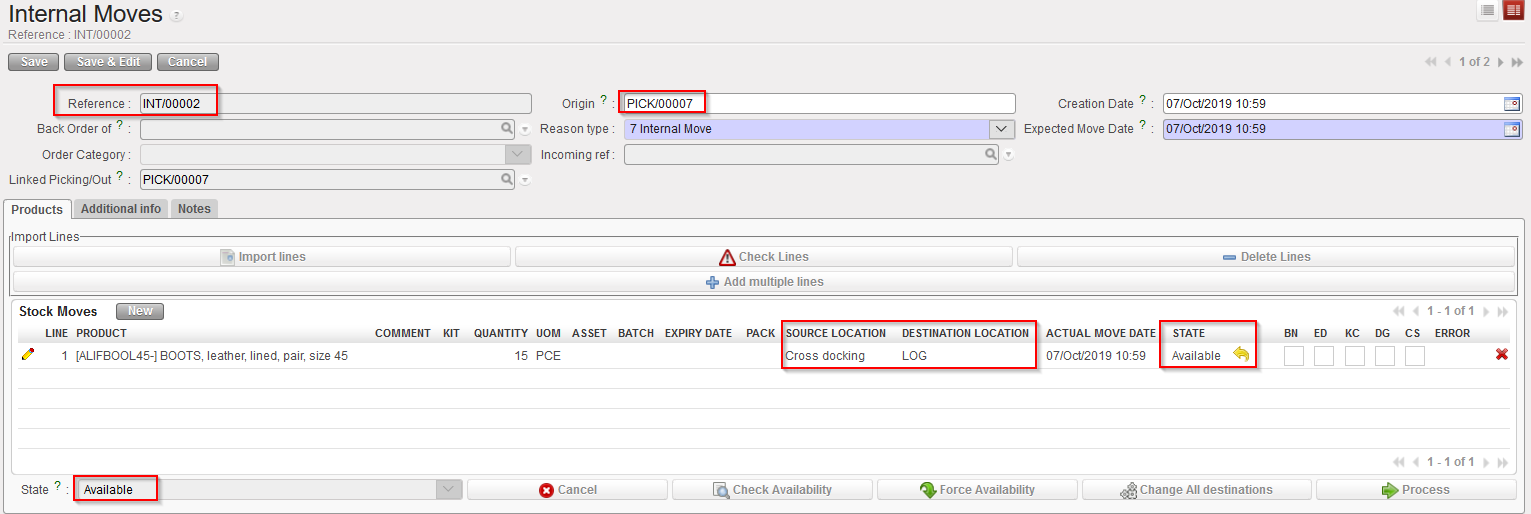

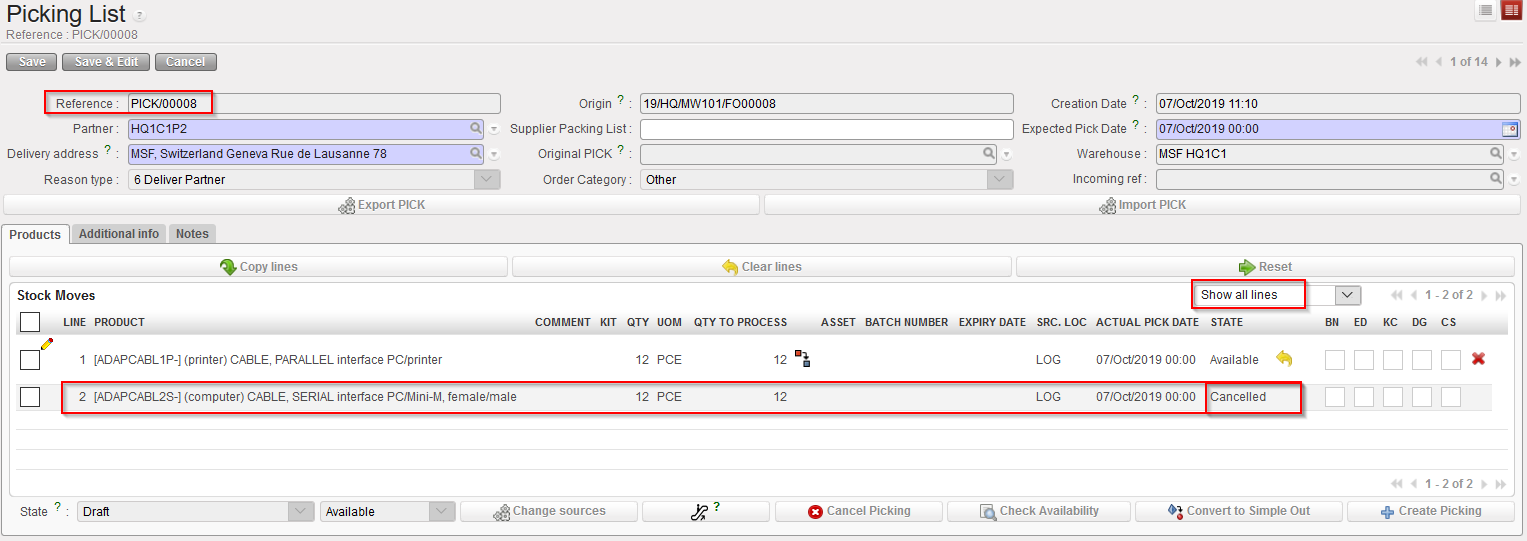

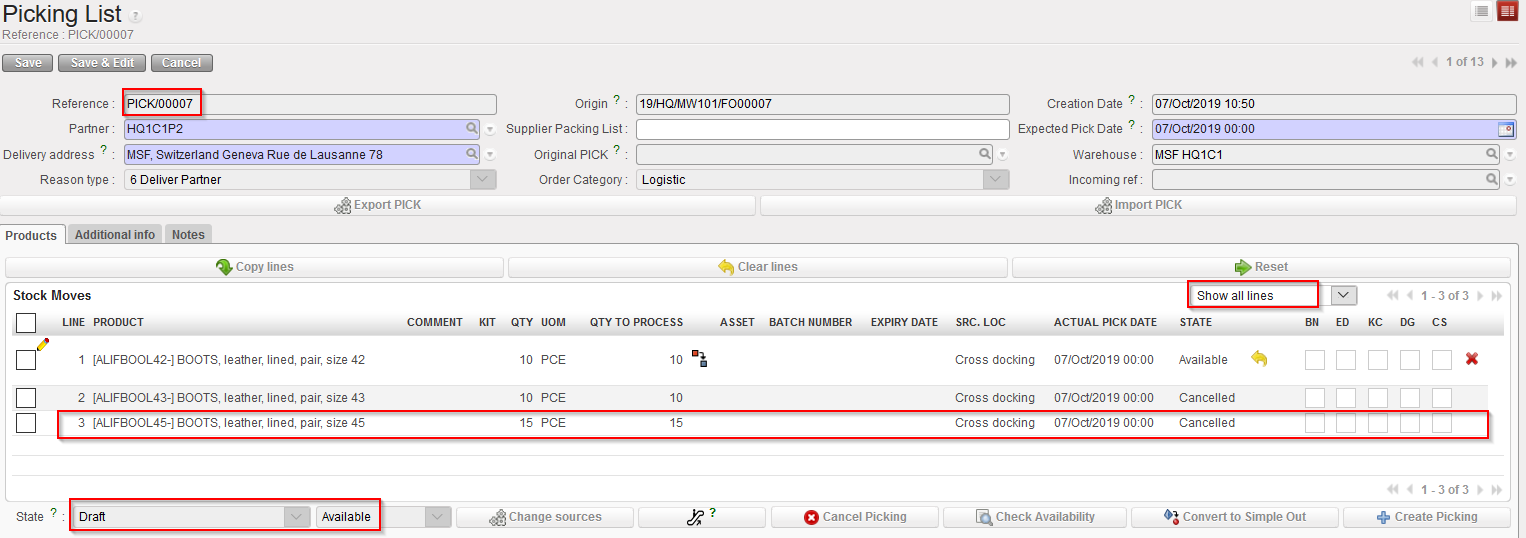

Results on the main PICK are the same in both cases.

|

|

|

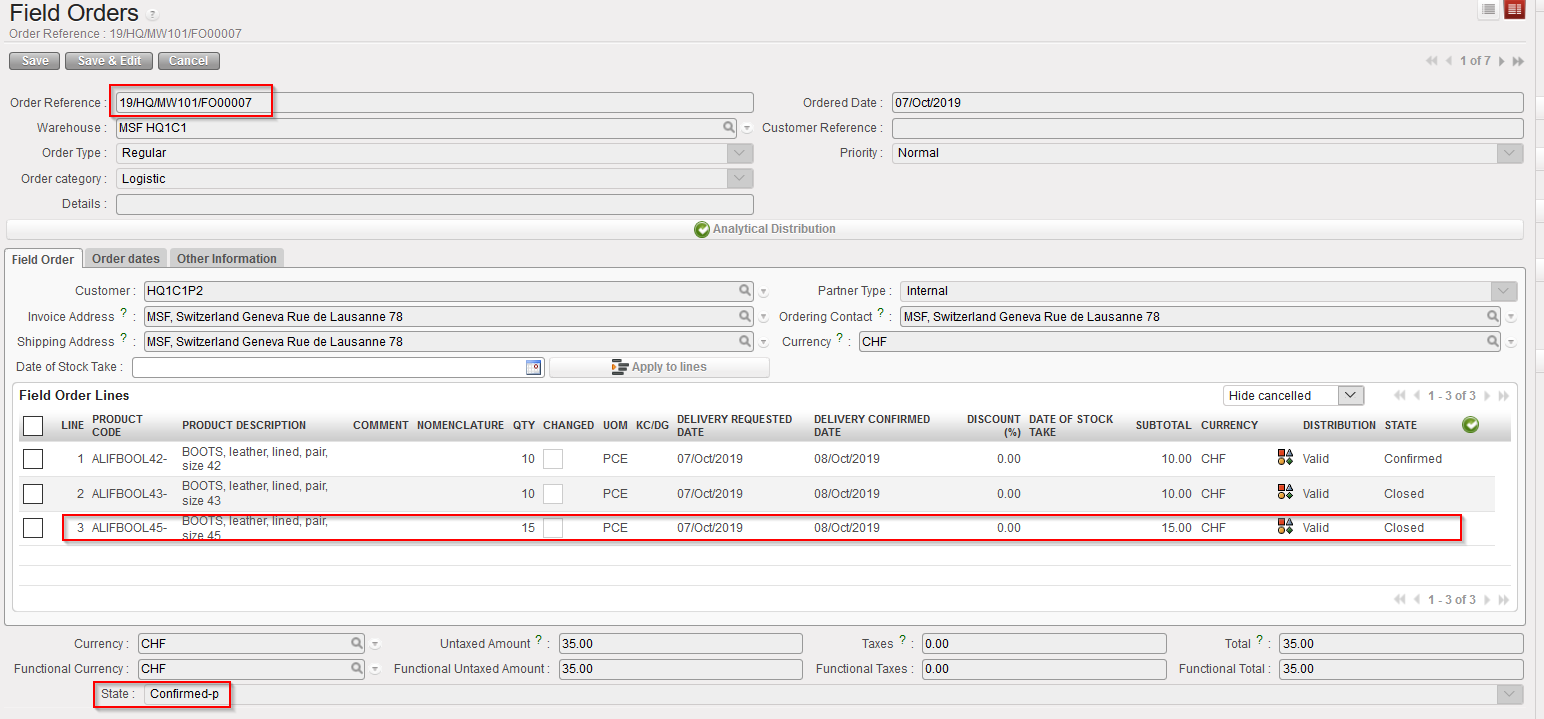

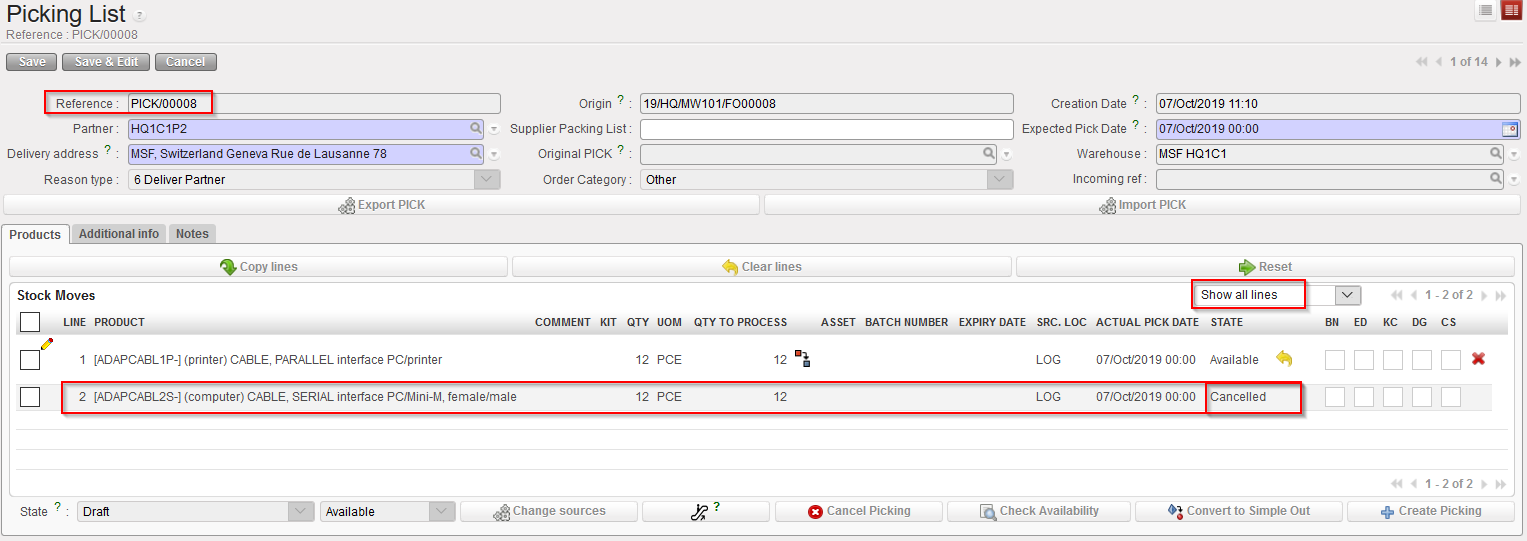

Cancelled line on a main PICK – please note that filter has been set to “Show all lines” in order to see the Cancelled lines

|

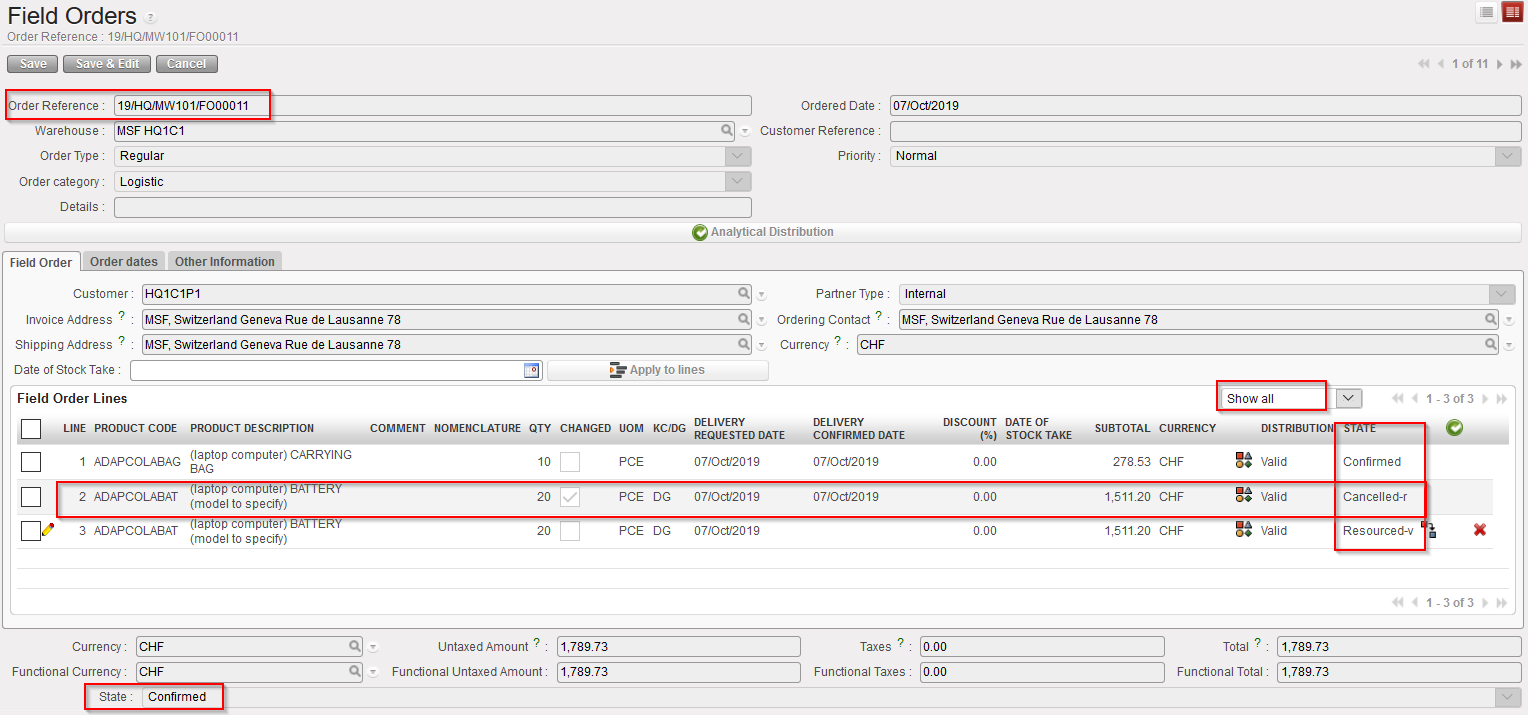

|

|

|

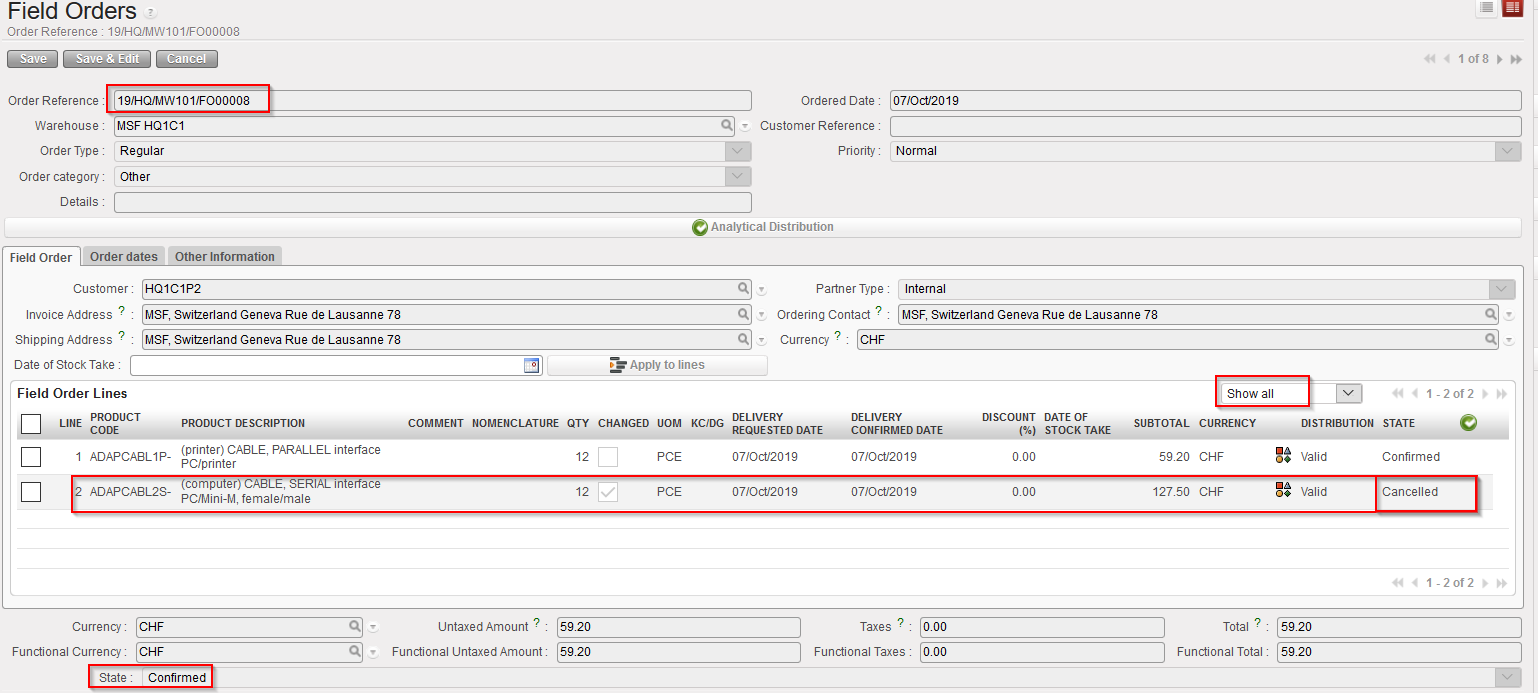

Closed line on the corresponding FO

|

On the main PICK, the cancelled line is now in state “Cancelled“.

On the corresponding FO, the line is now in state “Closed” (since FO since sourcing done from PO).

If the related IN has already been processed, goods are in the “Cross docking” location and the user must handle them manually.

4) Cancellation on main PICK at line level (with FO sourced from stock)

Go to: Warehouse / Warehouse Management / Deliveries / Picking

- Open the Picking Ticket on which you want to cancel a line (main PICK in this case)

- Click on the red cross located at the right of the line you wish to cancel

|

|

|

Cancelling a line of a main PICK

|

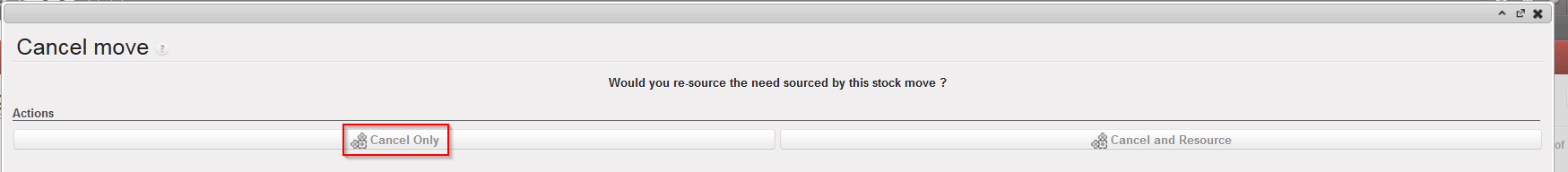

3. On the “Cancel move” window, select “Cancel Only“.

|

|

|

Cancelling a line of a main PICK

|

|

|

|

Cancelled line on a main PICK

|

|

|

|

Cancelled line on the corresponding FO

|

On the main PICK, the cancelled line is now in state “Cancelled“.

On the corresponding FO, the line is now in state “Cancelled“.

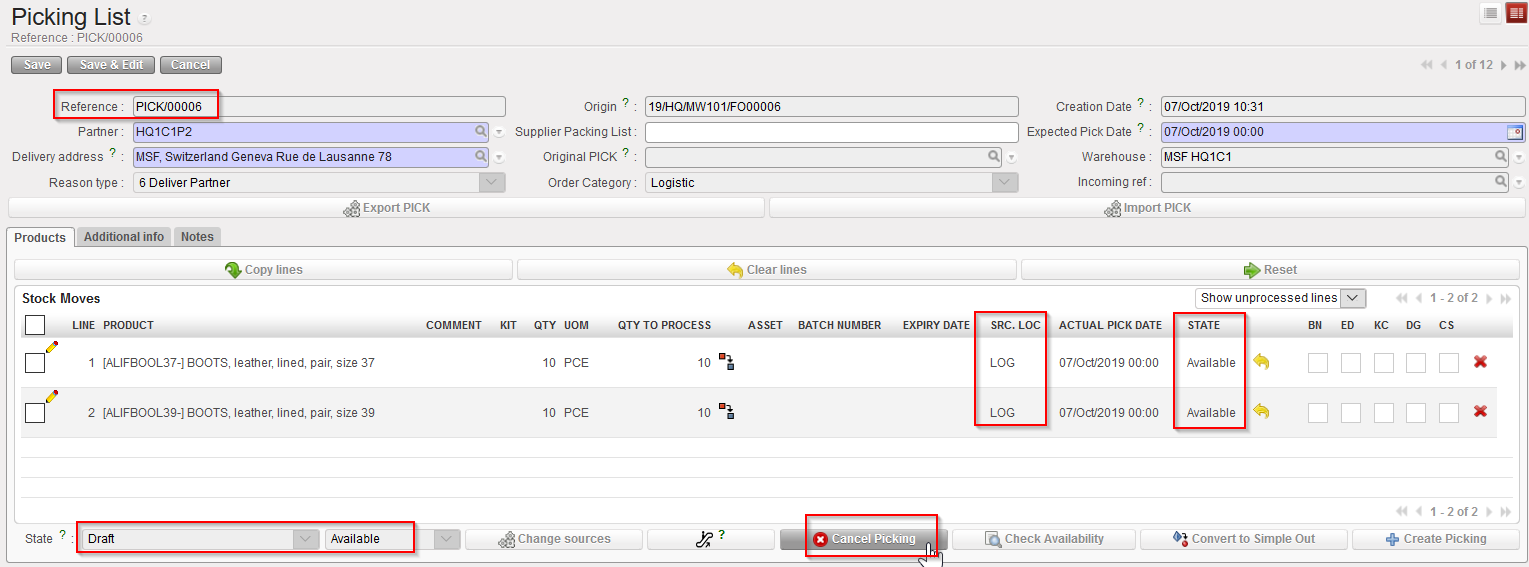

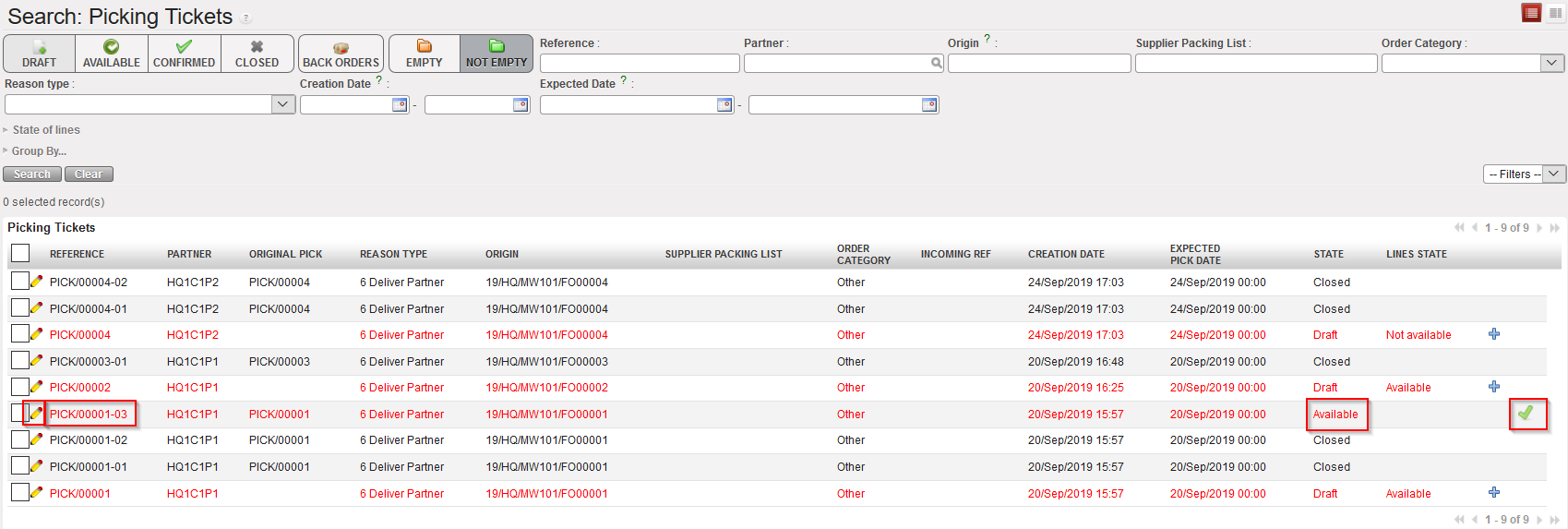

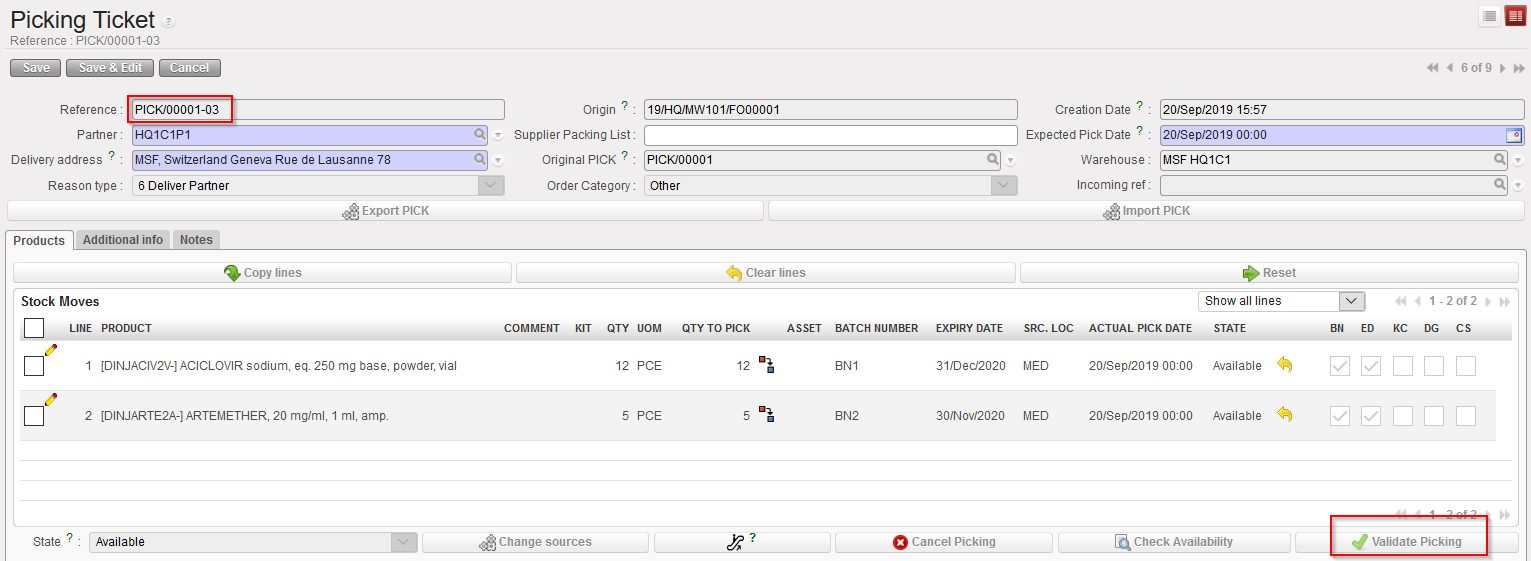

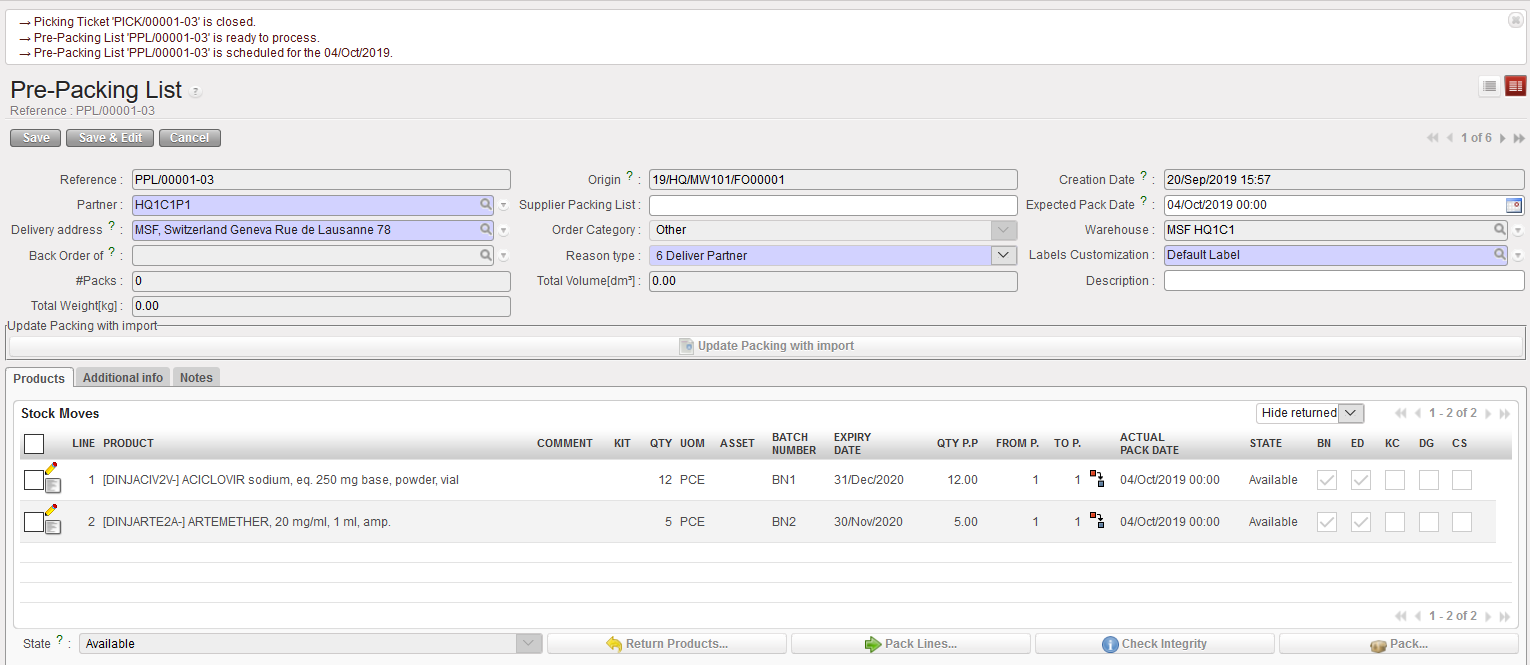

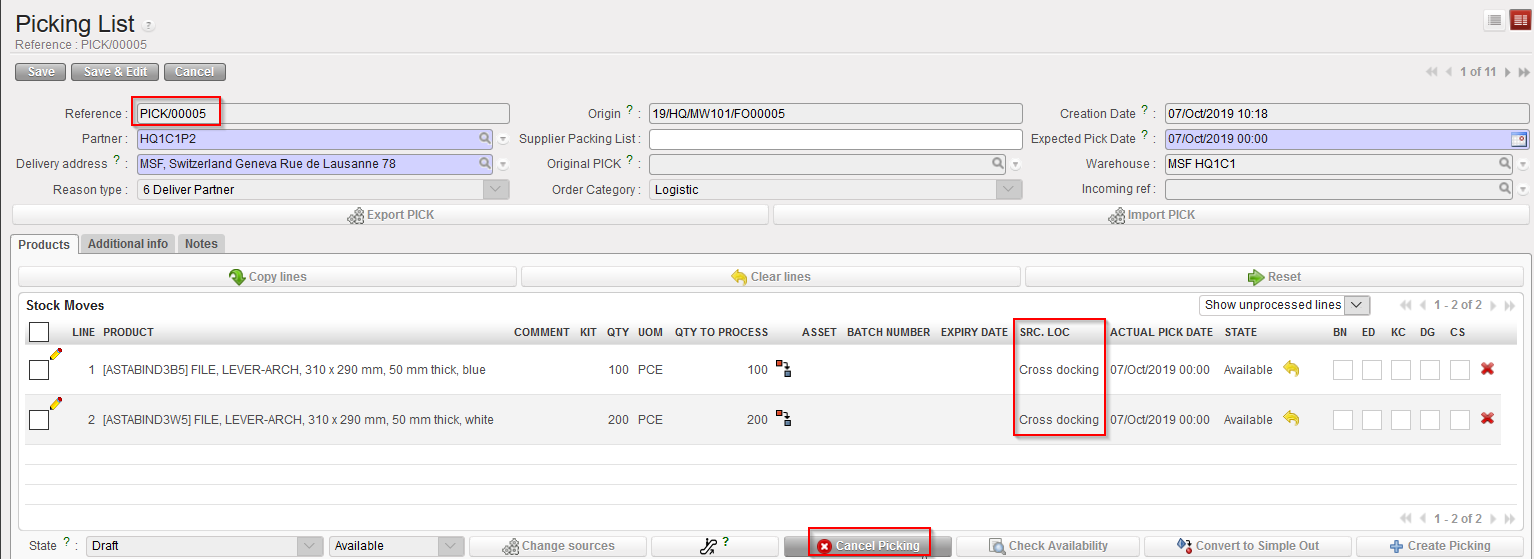

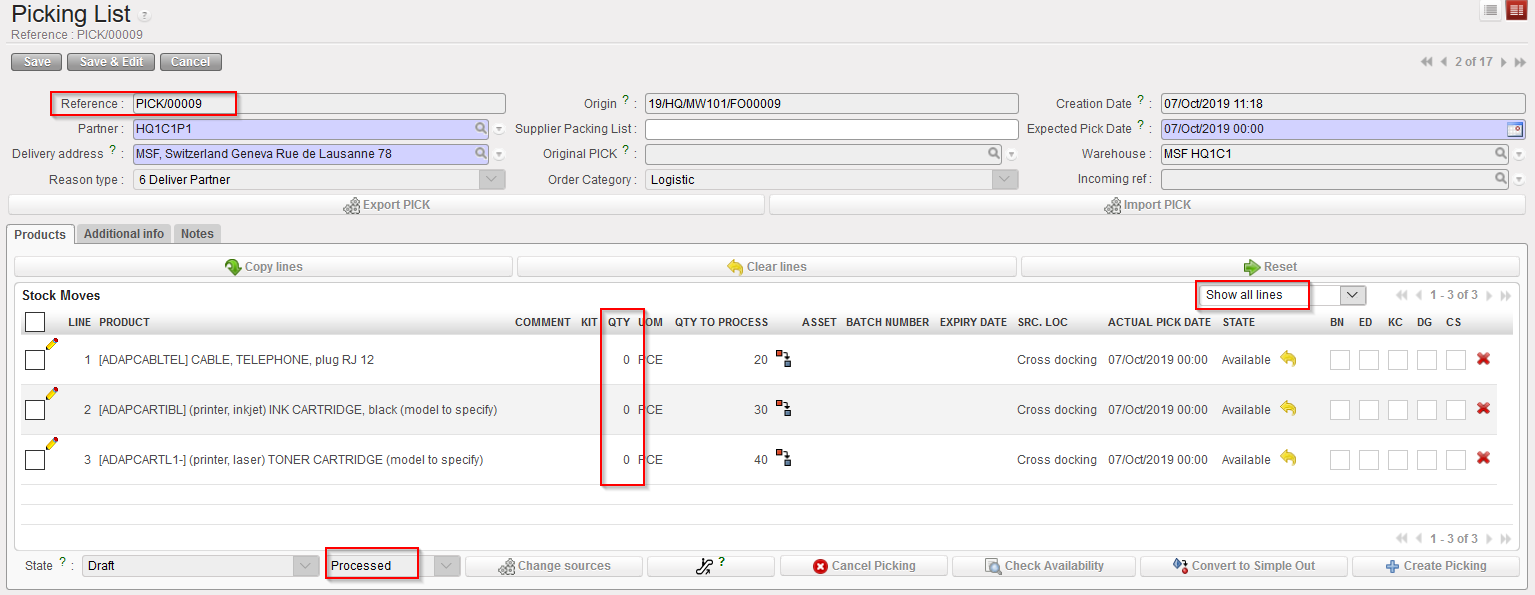

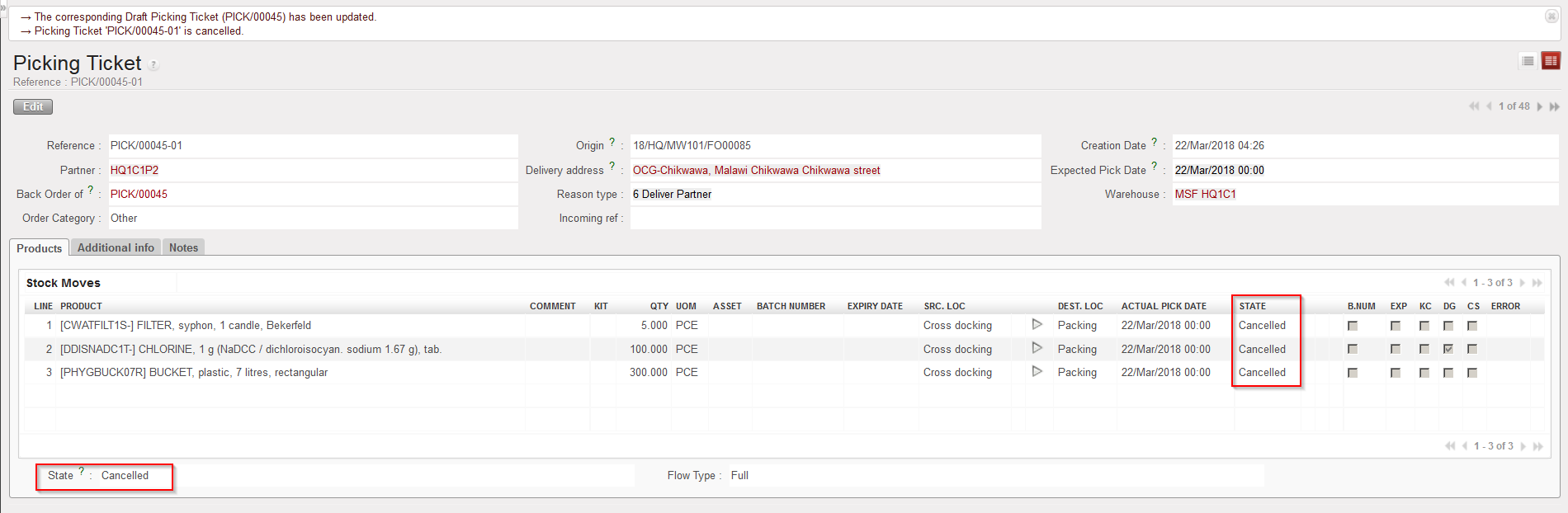

5) Cancellation on sub PICK

Cancellation on a sub PICK can only be done at header level. This cancellation will simply resend all the cancelled lines to the main PICK

Go to: Warehouse / Warehouse Management / Deliveries / Picking

- Open the Picking Ticket you wish to cancel.

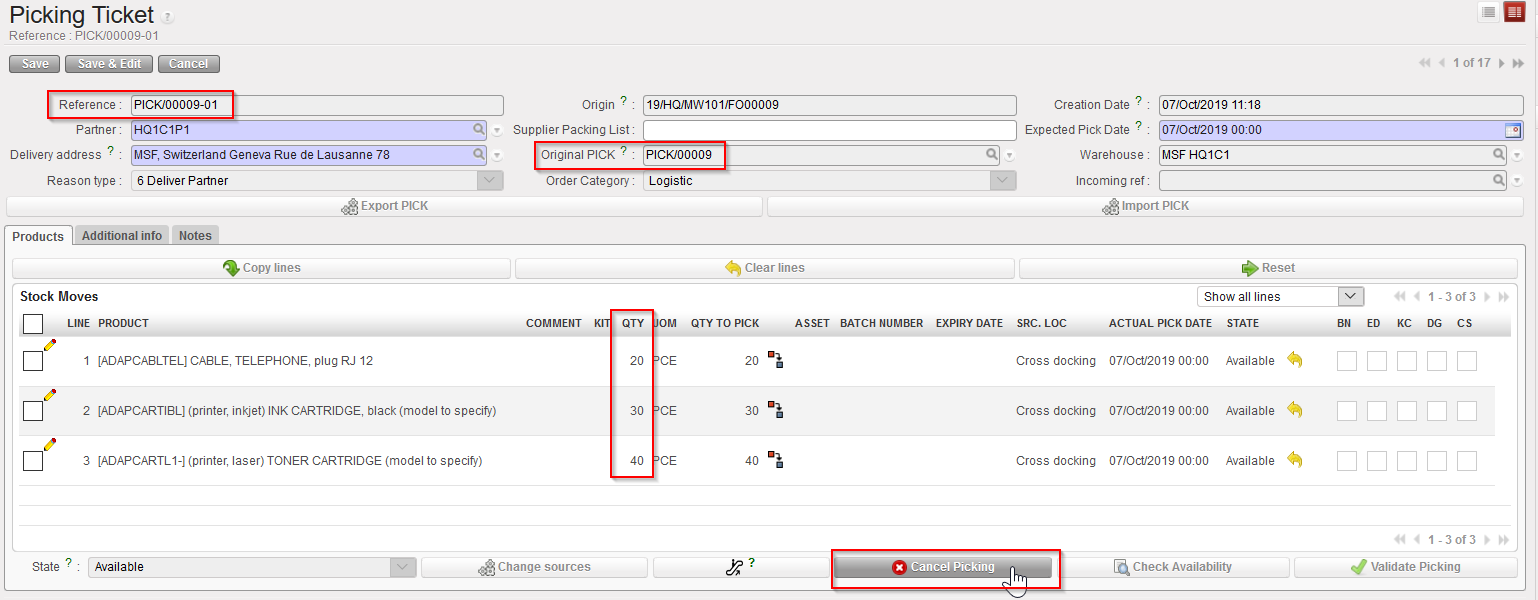

- Click on the “Cancel Picking” button located at the bottom of the screen.

|

|

|

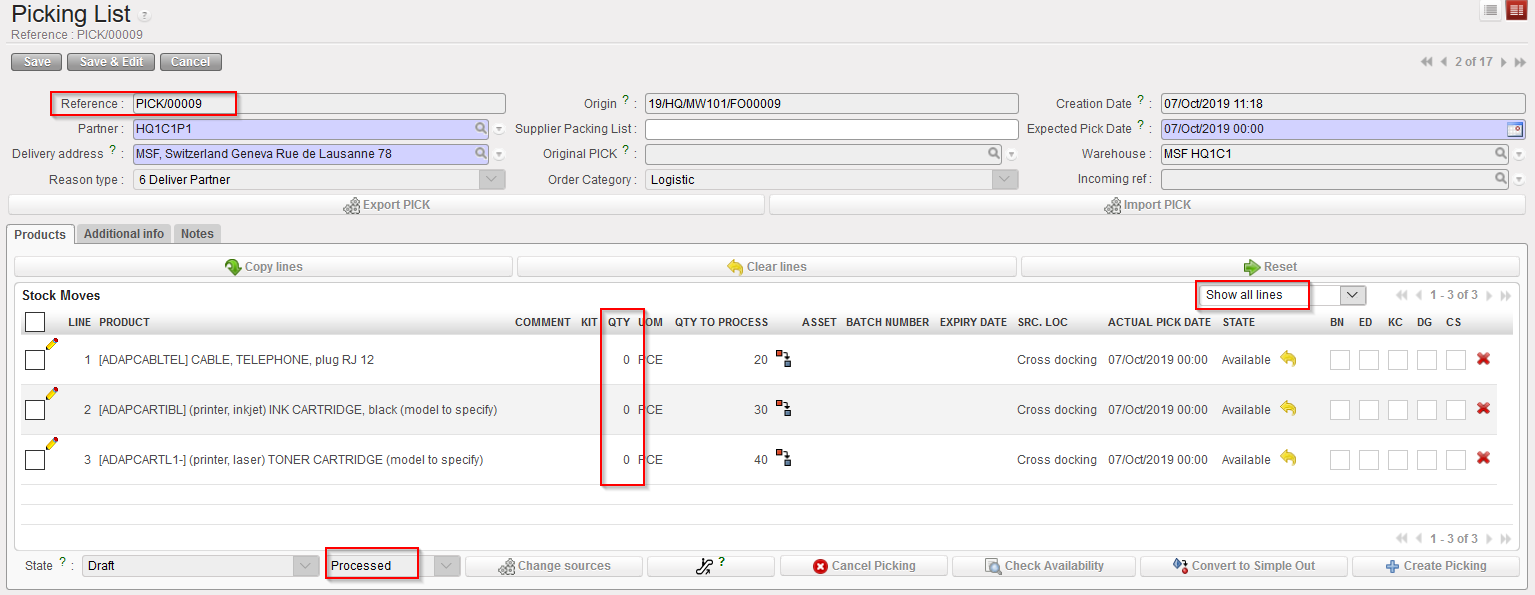

Main PICK before cancellation on sub PICK – with filter on “Show all lines”

|

|

|

|

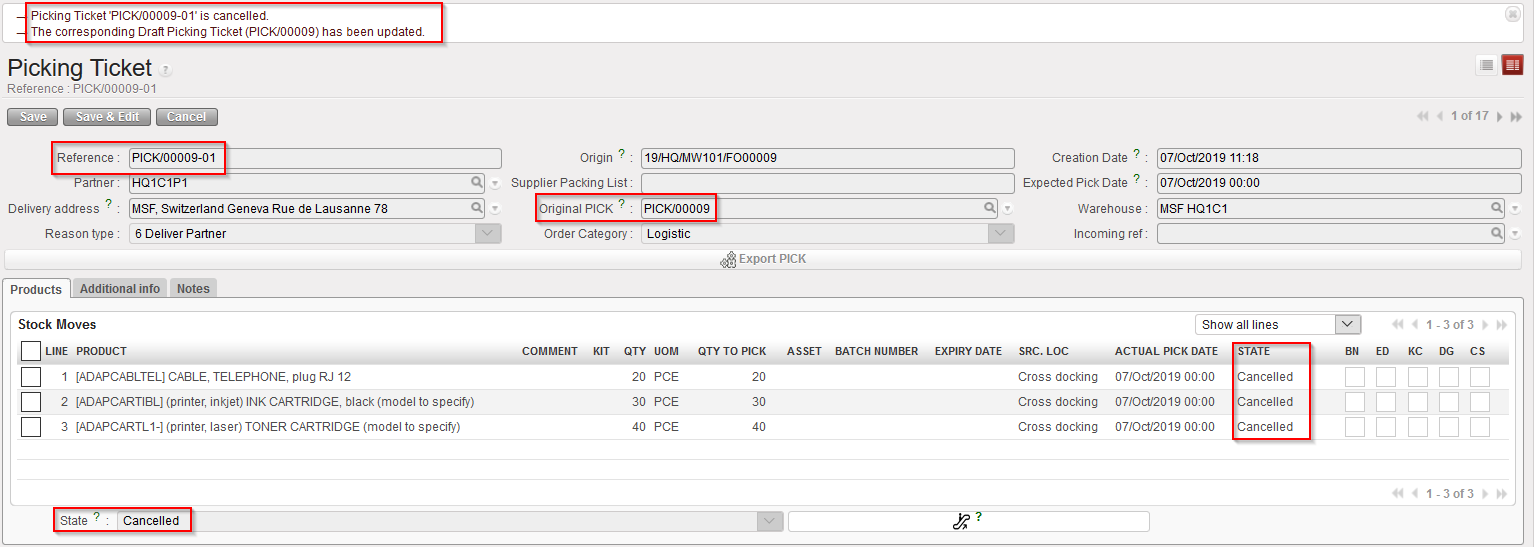

Cancelling a sub PICK

|

|

|

|

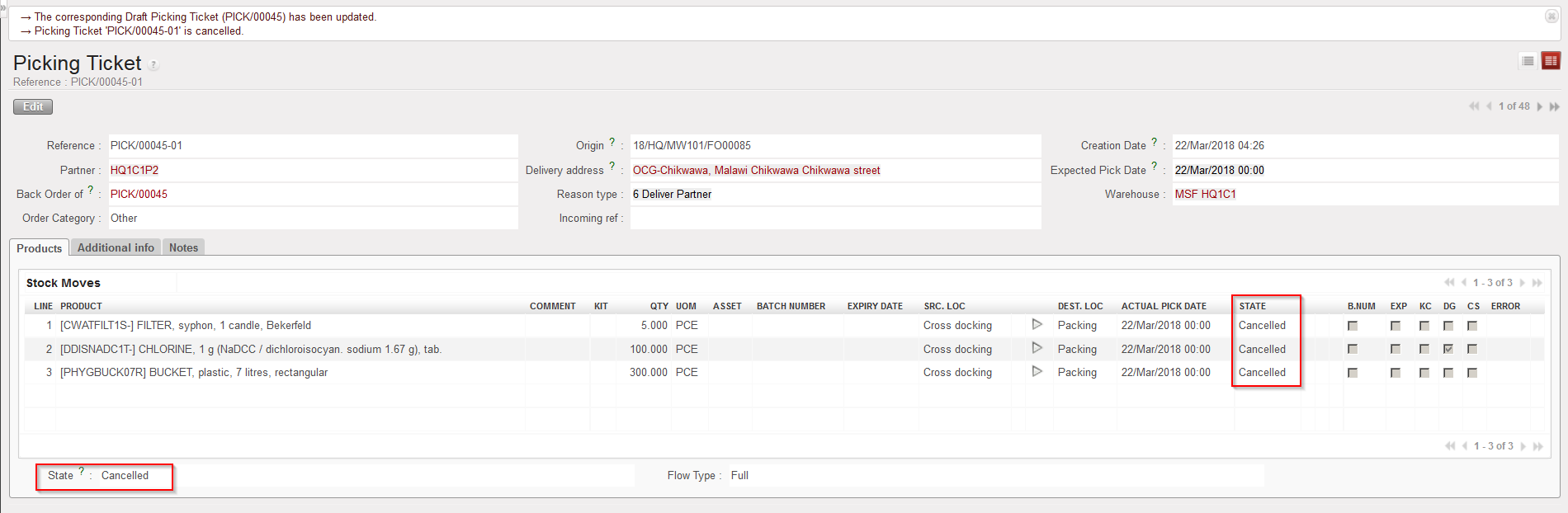

Cancelled sub PICK

|

|

|

|

Main PICK after cancellation of sub PICK

|

The system informs you that the SUB pick is cancelled and that the corresponding main PICK has been updated. Lines cancelled on the sub PICK are transferred back to the main PICK (No impact on FO).

6) Conclusion of the section

Different scenarios involving cancellation on Picking Tickets have been outlined above. Many alternative scenarios exist involving partial validation of FOs or POs, partial sourcing of FOs, partial confirmation of POs, partial reception of INs, partial picking,…

These various scenarios will have various consequences.

According to the scenario, cancellation on PICK may require manual action of a user who could also have to manually cancel or close related documents (FOs, INs, POS,…).

Note that you can check the “Unreserved Stock report” to see all the Cancelled products that have been sent to Cross Docking ( LU-SU4302 Stock Inventory Report – G. Unreserved Stock report)

The functionality Tools / Documents ‘In Progress‘ may be useful to help you with this as it will close the selected document and cancel any associated documents.