Supply User Manual ENG -> Products -> 3.7 Products Reports -> A. Report for product inconsistencies – Batch/Expiry Date

A. Report for product inconsistencies – Batch/Expiry Date

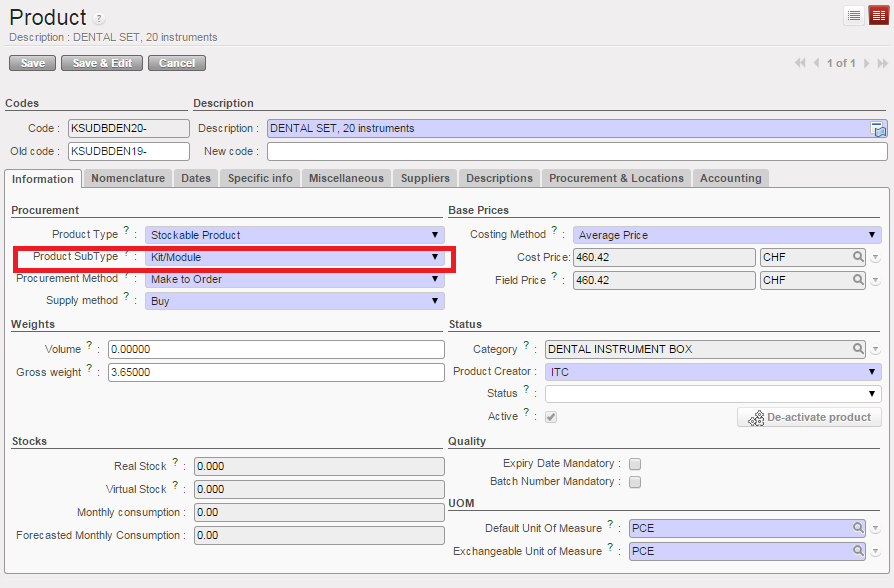

Due to some modifications on Product attributes after a product was already in use, there have been cases where a product has a batch and expiry date existing in stock while the current product does not have these attributes active (or vice versa). Normally this should not be the case, but in order to check where this inconsistency exists, the report BN/ED Inconsistencies Report can be generated for each instance:

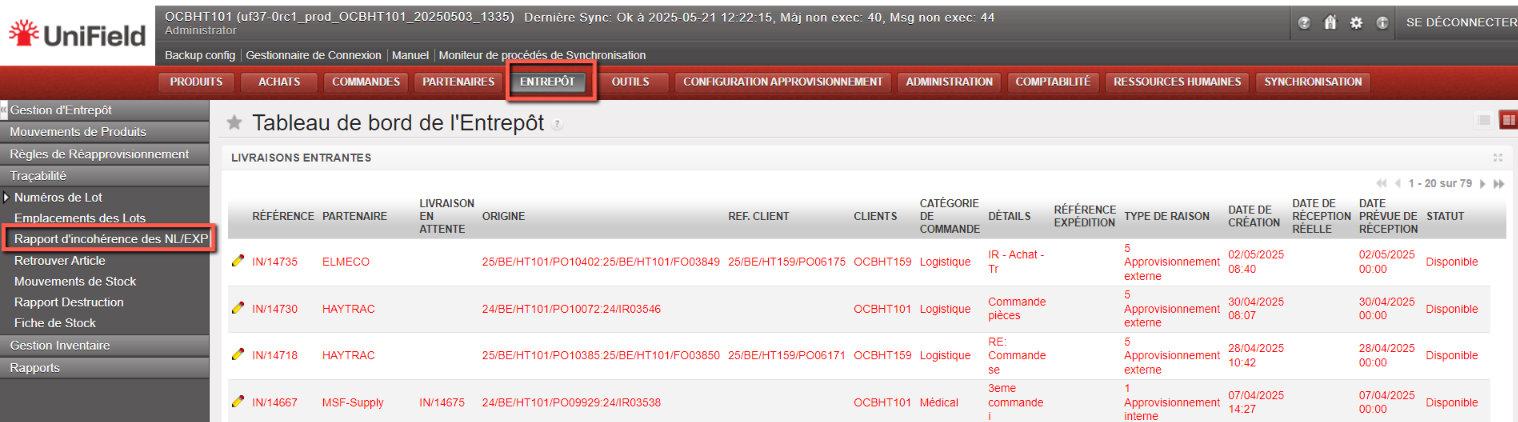

Go to: Warehouse>Traceability>BN/ED Inconsistencies Report

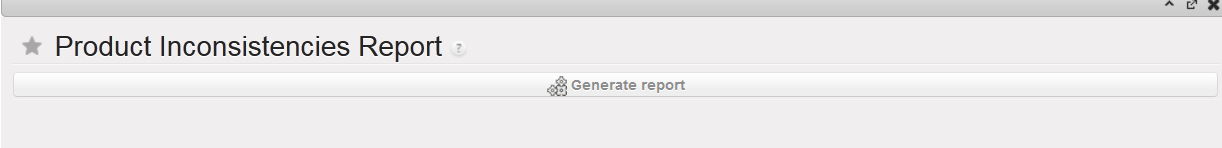

Product Inconsistencies report

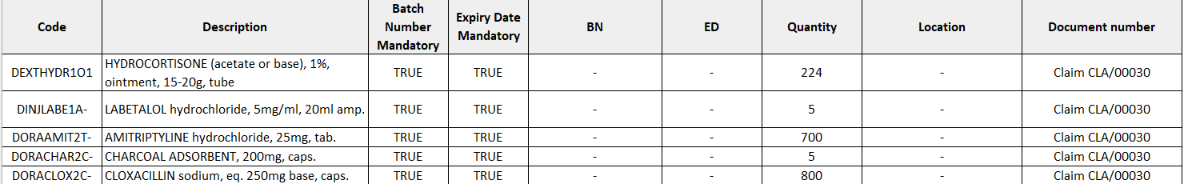

The excel report generated will show all products in the instance where the current Batch or expiry date attributes do not correspond to those of the same product which is either in stock or in a transport document. The report shows the “true” attributes of the product according to the product data sheet in the “Batch Number Mandatory” and “Expiry Date Mandatory” columns, and then will show all relevant information for inconsistent quantities and batches of this product with quantities present in any location or any transport documents (Picks, OUTs etc) which contain them. Please refer to your OC policy before taking any action on these.