Supply User Manual ENG -> Products -> 3.2 LU-SU2101: General Product Management -> C. How to activate and deactivate a product

C. How to activate and deactivate a product

It may be necessary to de-activate a product in your instance, for example because it should no longer be used or has been replaced. Before the system can deactivate a product, it will check if there is any open Supply document containing the product, and also for some Finance documents, or if it exists in any internal stock location. In that case, the product should not and cannot be de-activated.

Please note that thanks to the UniData linkage, the product de-activation can also been done automatically via synchronization when product is “Unsubscribed” or Archived in UD and that no Stock/ Pipeline are in the instance (otherwise it will be Phased Out).

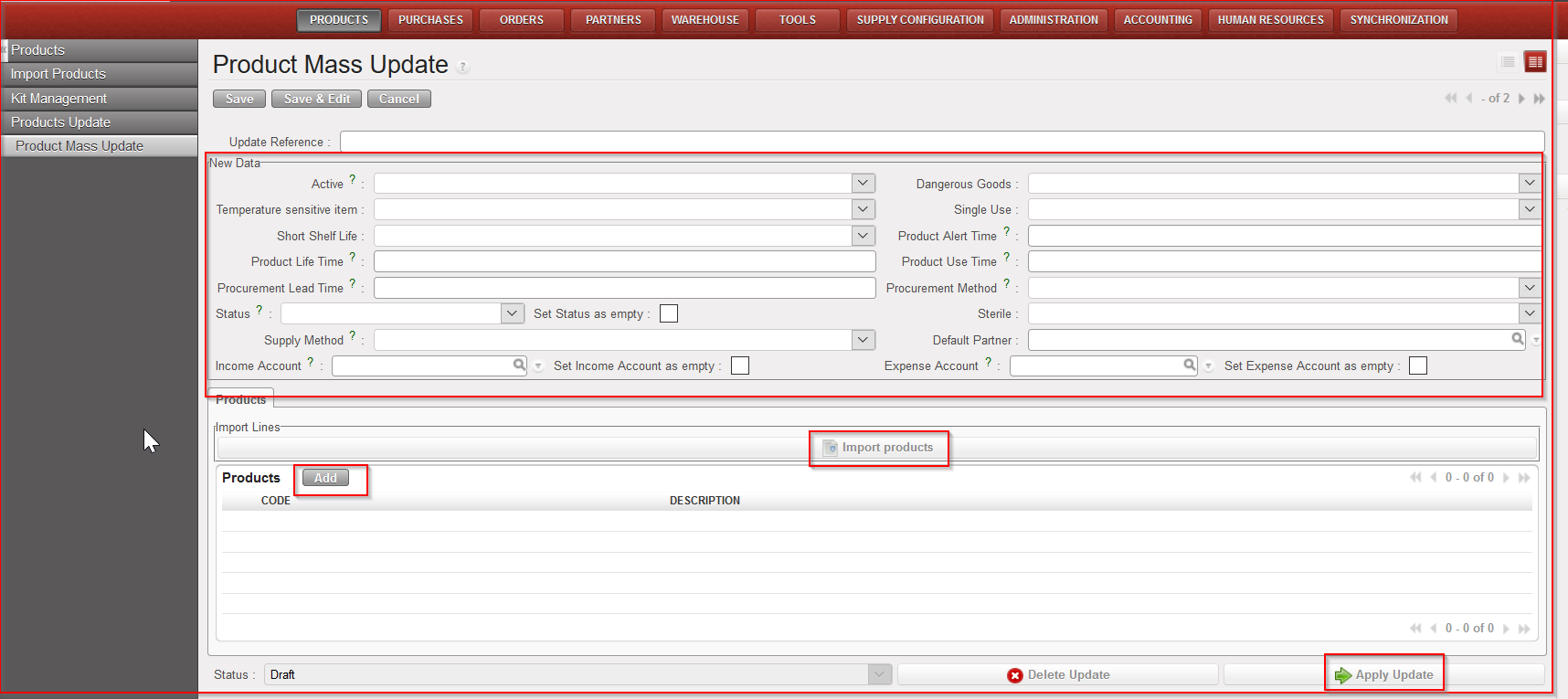

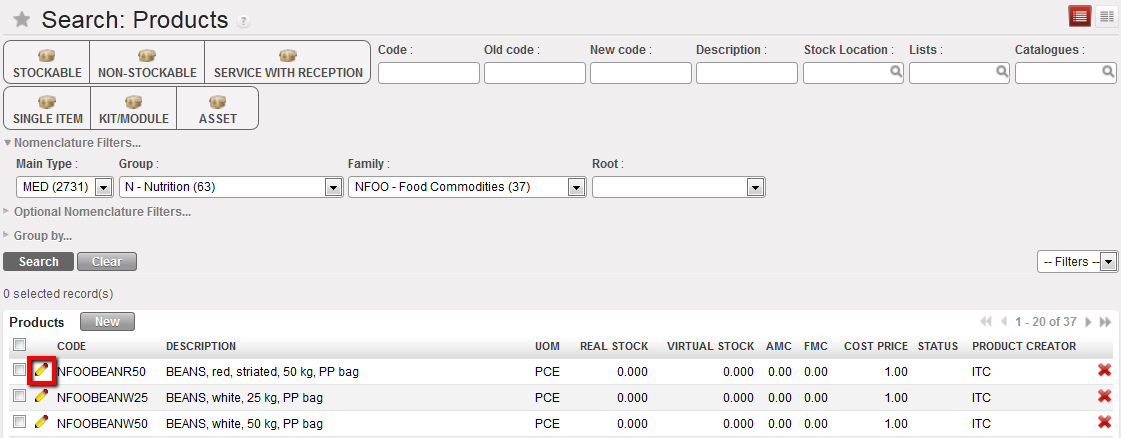

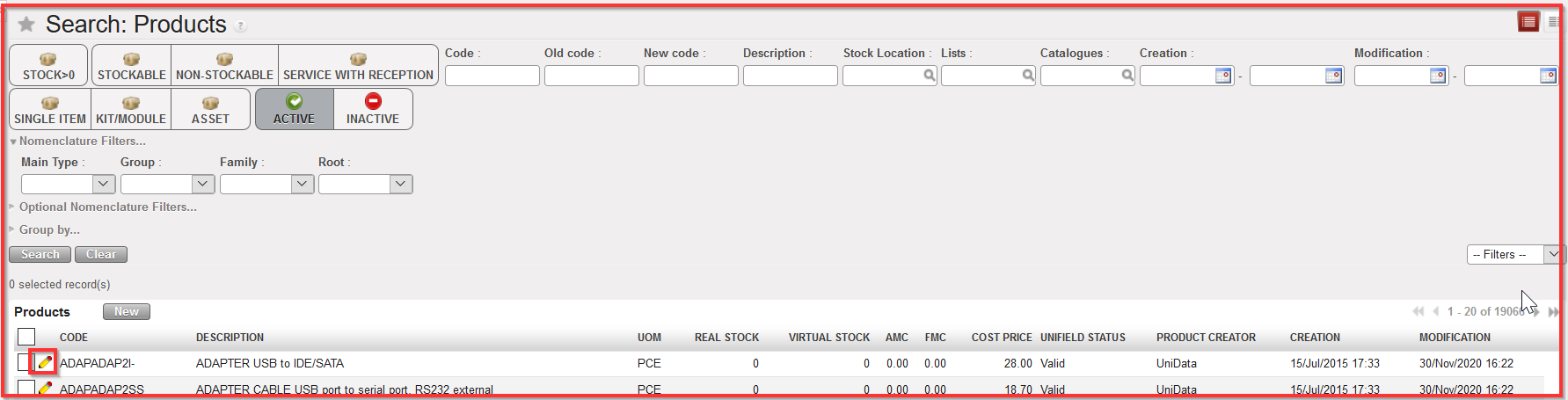

To de-activate a product –> Go to: Products / Products

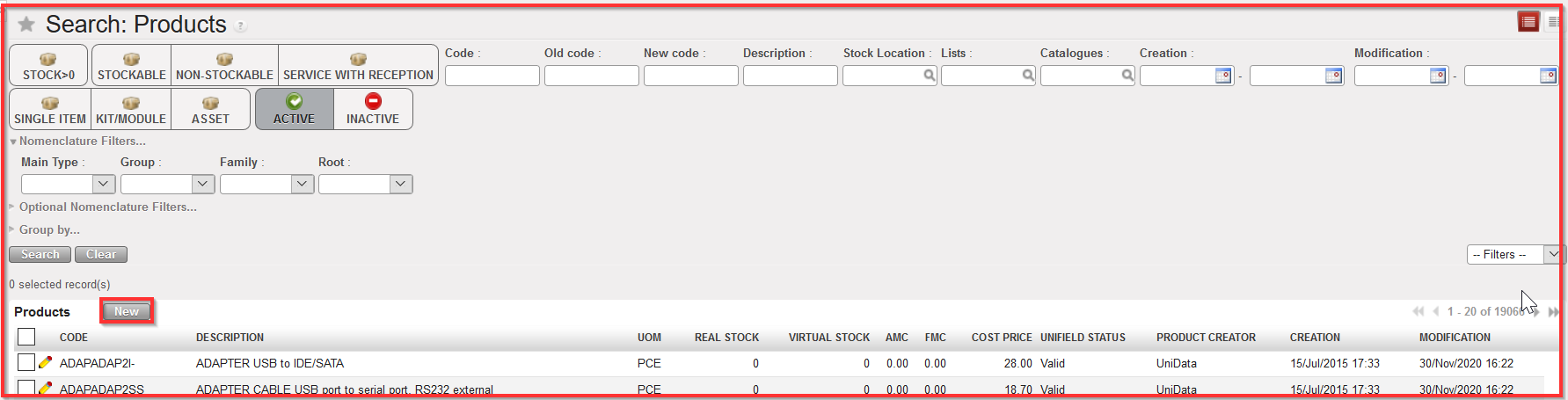

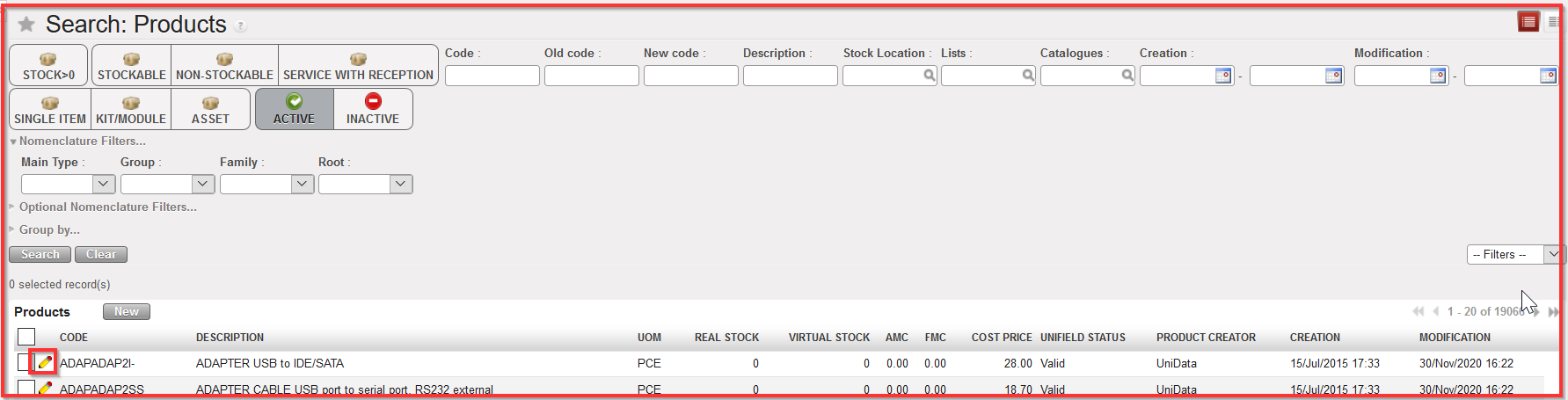

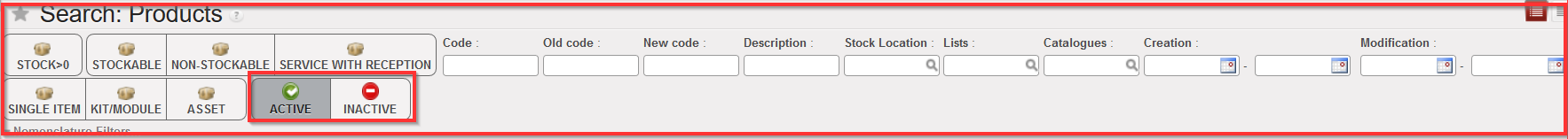

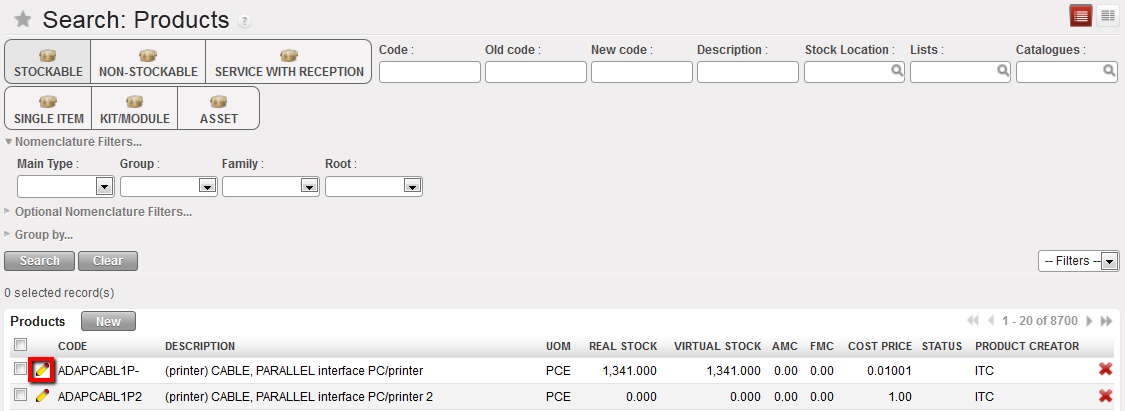

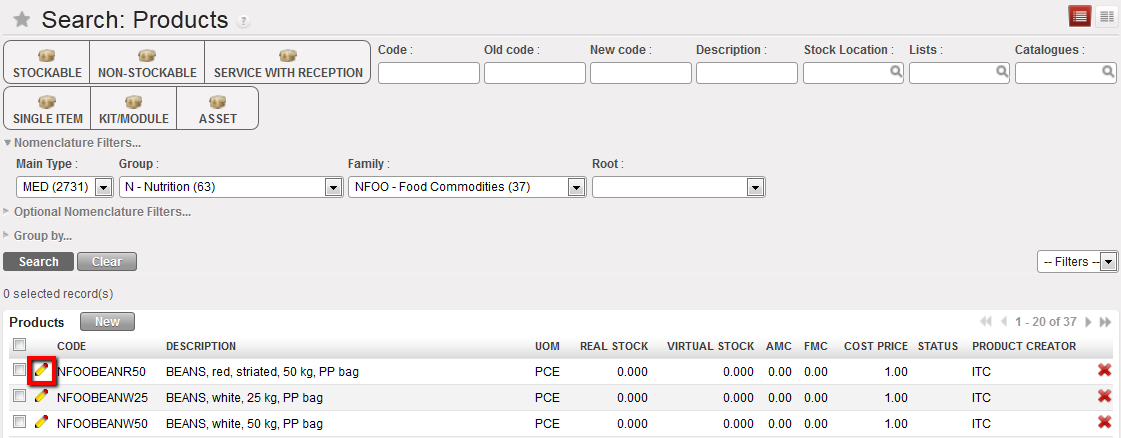

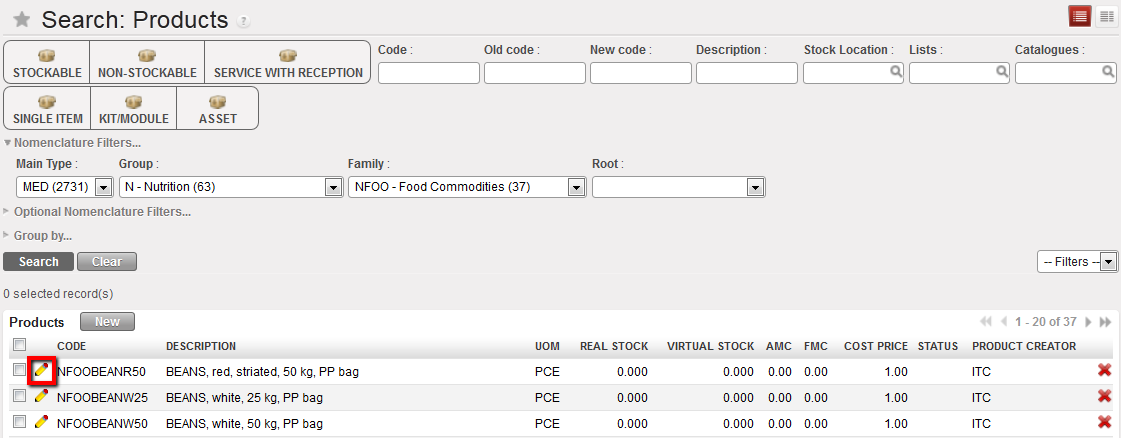

- Use the relevant filter values to find the product you want to edit.

Editing a product form to de-activate it

2. Click on the pencil icon

of the selected product to open it in edit mode.

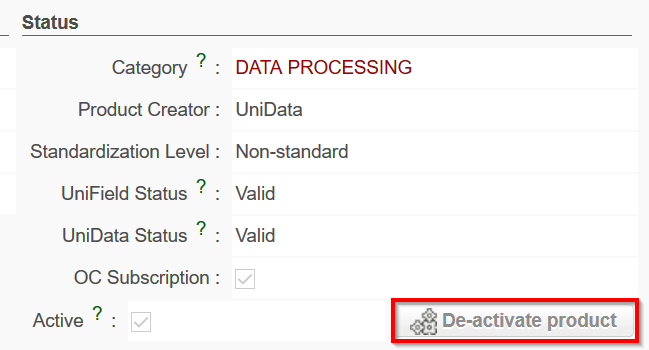

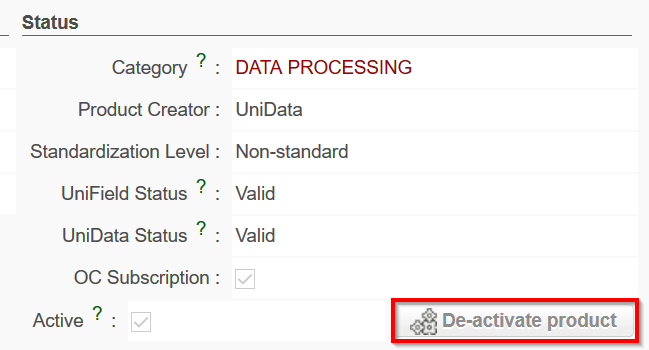

3. In the Status section in the Information tab, click on the “De-activate product” button.

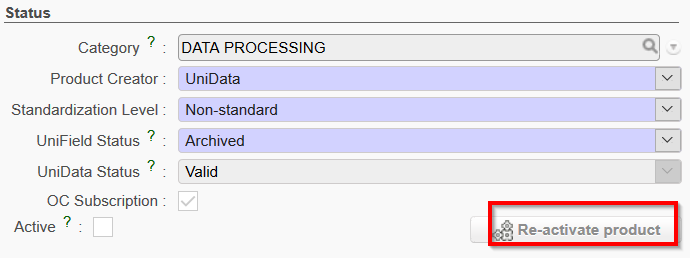

De-activate product

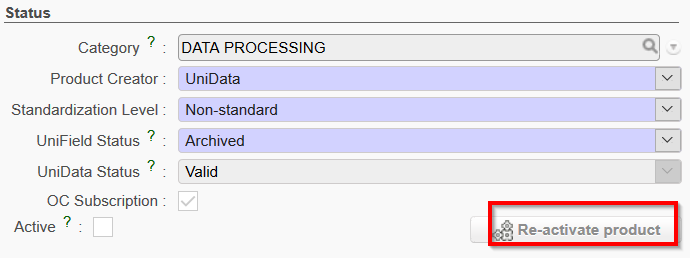

4. If the product is not in any open Supply transaction documents nor in restricted Finance documents, or present in any internal stock location of your instance, the “Active” checkbox will now be empty, and the “De-activate product” button will have been replaced by a “Re-activate product” button (see picture below). This button will leave the option to reactivate the product if needed. Note that this reactivation can also be triggered by a UD update.

Also, after deactivation “UniField status” is set to “Archived”.

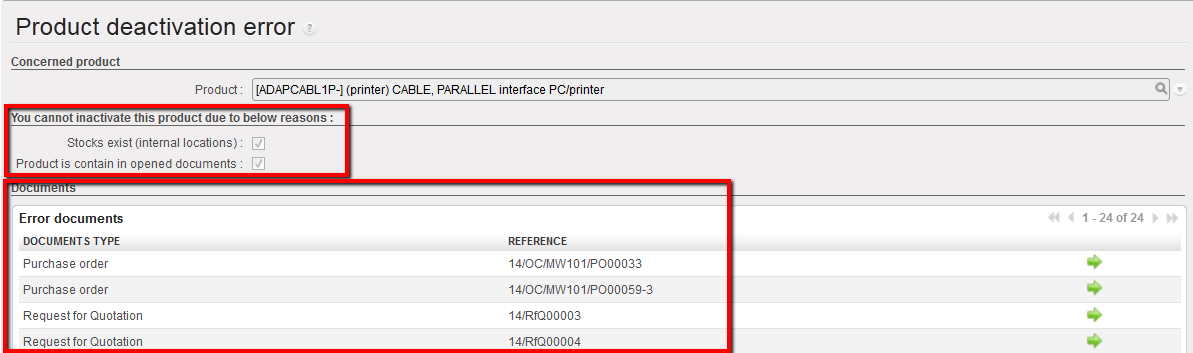

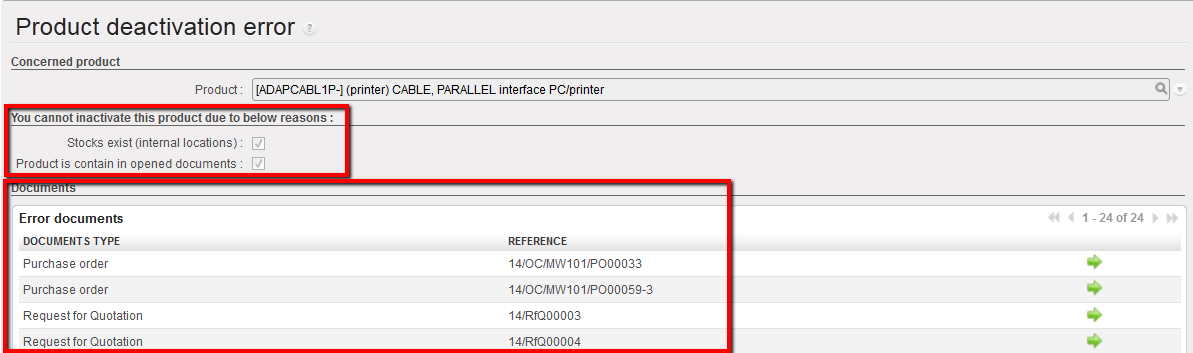

However, if the product happens to be in any open Supply or certain Finance transaction documents and/or is present in any internal stock location of your instance or on an active Product list, a “Product De-activation Error” screen will appear (see next picture).

Product de-activation Error

5. This indicates why you cannot de-activate the product via the checkboxes which will show whether the product is present in any internal stock location of your instance “Stocks exist” and / or if the Product is contained in any open (transaction) documents.

6. In the “Documents” section, all documents which contain the product will be displayed, and at the end of each line, there will be a green arrow which opens the document when clicked on.

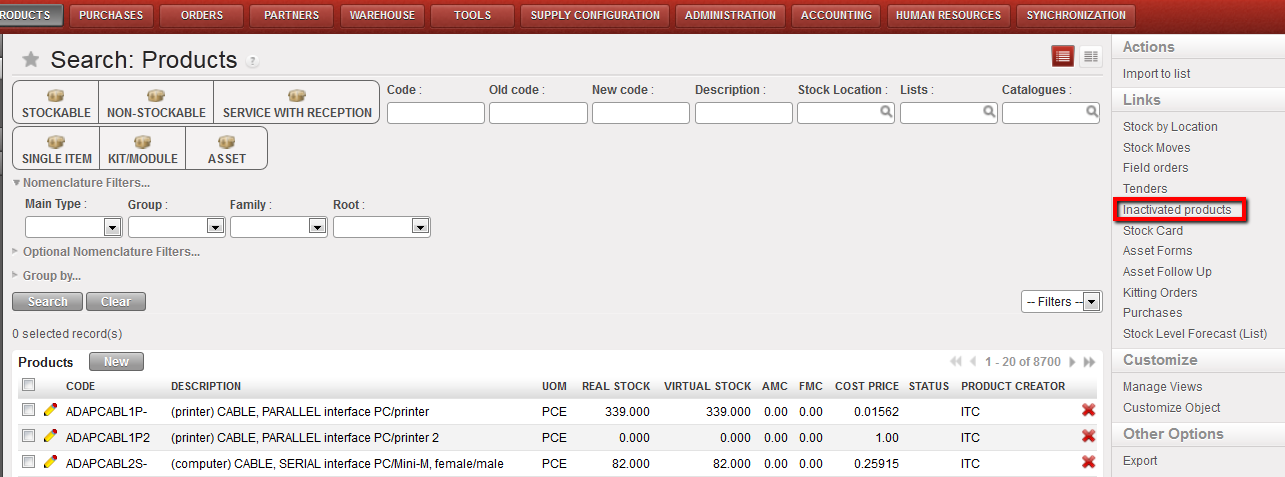

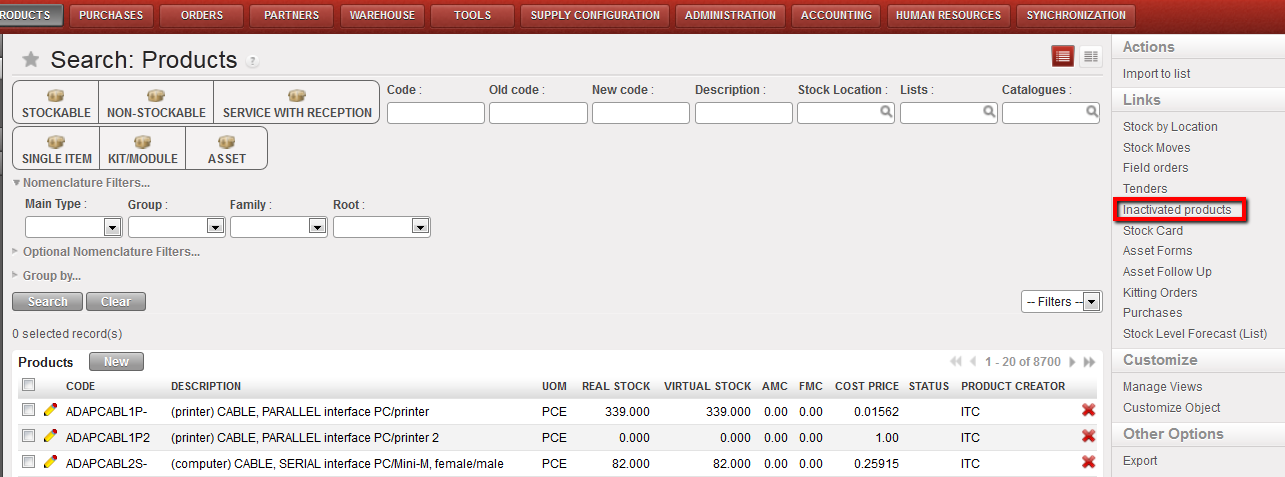

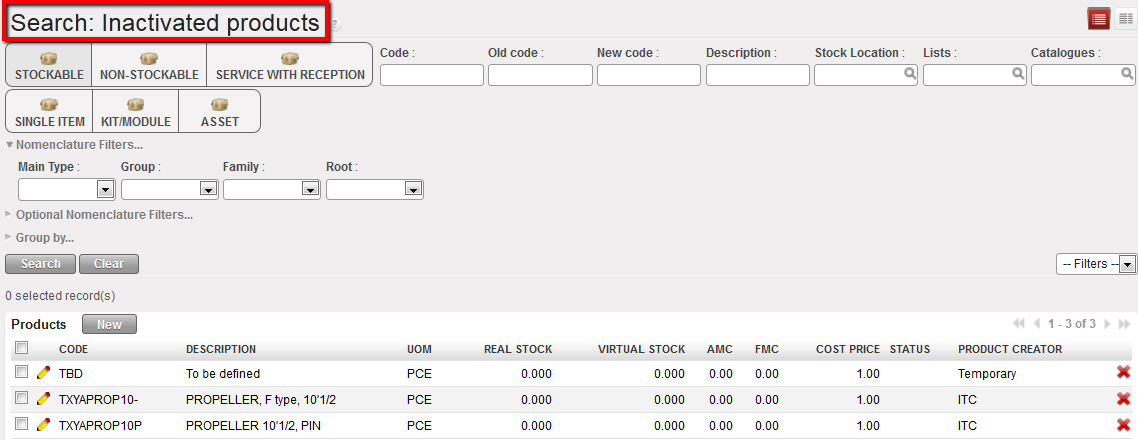

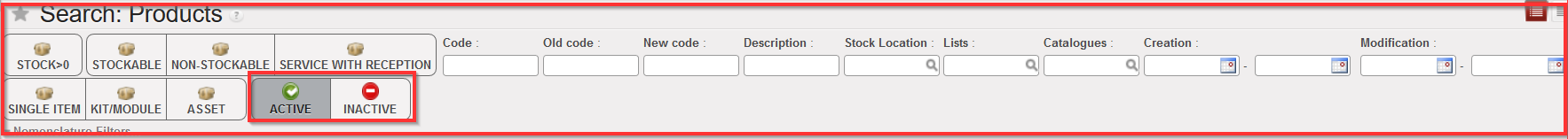

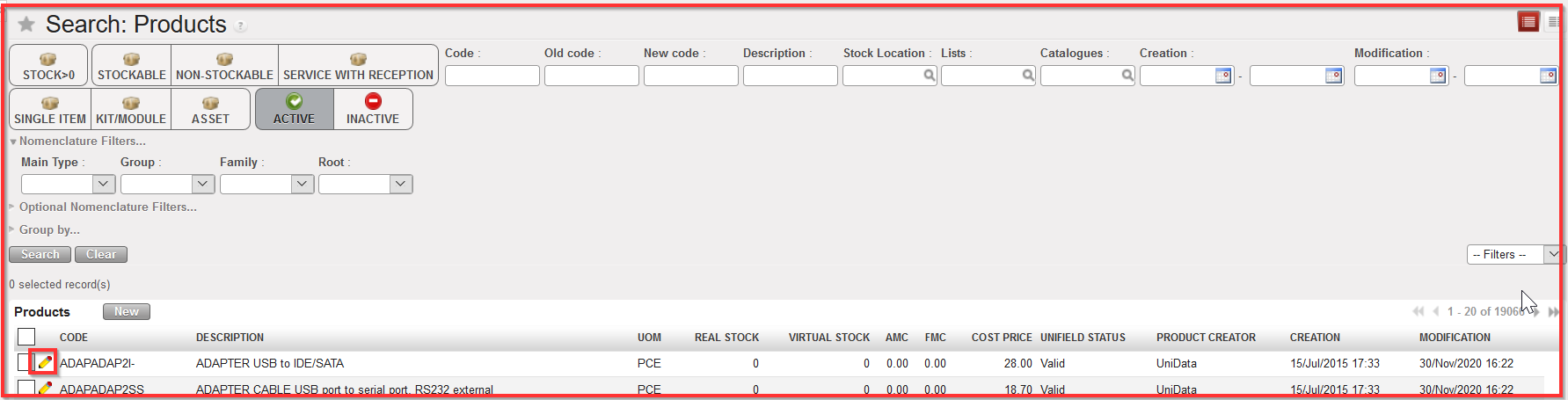

Please note: When a product has been successfully de-activated, this means it cannot be viewed or selected from the database when creating transaction documents (e.g. Purchase Orders etc), but can still be seen by searching directly in the “Products” business application. If you wish to see all de-activated products, this can be seen from the Products Action Menu Link “Inactivated Products” or filter button “Inactive” (header right hand)

Please note: When a product has been successfully de-activated, this means it cannot be viewed or selected from the database when creating transaction documents (e.g. Purchase Orders etc), but can still be seen by searching directly in the “Products” business application. If you wish to see all de-activated products, this can be seen from the Products Action Menu Link “Inactivated Products” or filter button “Inactive” (header right hand)

Note: When a product is de-activated in one instance, the status changed from Active to Inactive, will be synched to any below instances, and if their is no stock or transaction open, the product will be set to be Inactive.

In case of synched flows between Instances with different products (e.g. Intermission or Intersection), when PO or FO is created by synch and includes a product which does not exist in the receiving instance, there will be a message onscreen on the relevant document (PO or FO) and a clear Not Run message created, warning the user that (PO/FO) product lines could not be created.

De-activated /Inactivated Products link

De-activated /Inactivated Products link

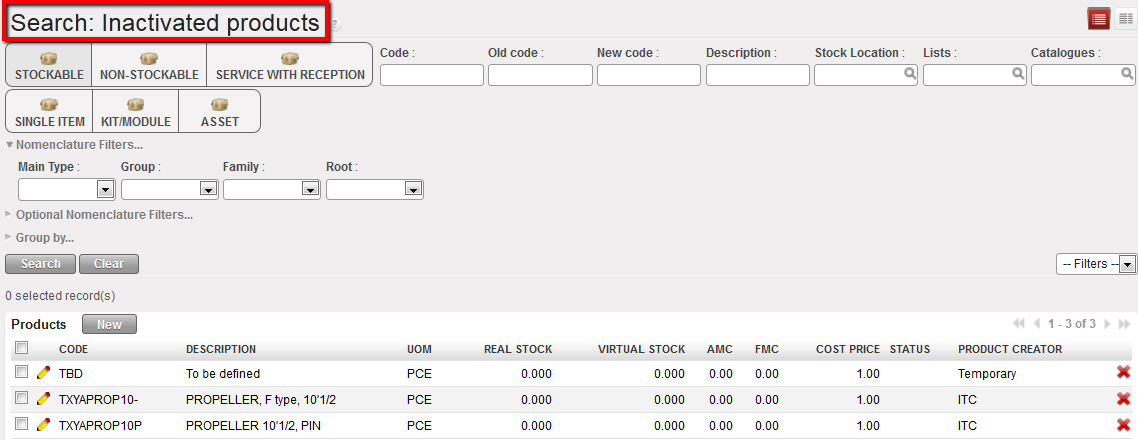

List of Inactivated products

Inactive button filter

Please note: Non-Standard Local UniData product are first synchronized down from HQ to mission (COO/project) as Inactive. They can only be activated at Coordination, in the condition that product is subscribed by the OC, if NSL product has been unsubscribed by the OC, it cannot be activated at mission level unless the product code is resubscribed.

When activating these NSL products, the following warning message is displayed:

When activating these NSL products, the following warning message is displayed:

“Warning!

This is an NSL product, please ensure that there is no duplicate “Local” product with which this product should be merged. If you activate and start to use this product it will no longer be possible to merge it with another.” (see “Merge” feature below in section L).

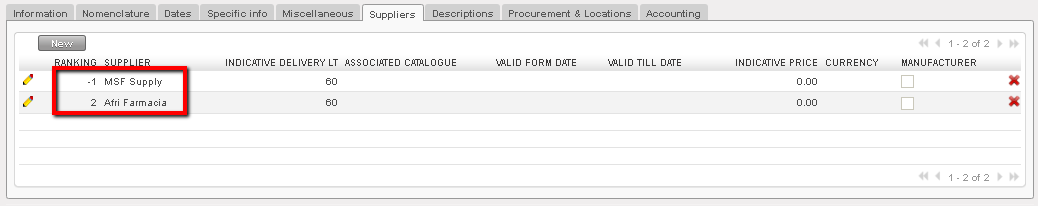

next to the product line to open it in edit mode

next to the product line to open it in edit mode

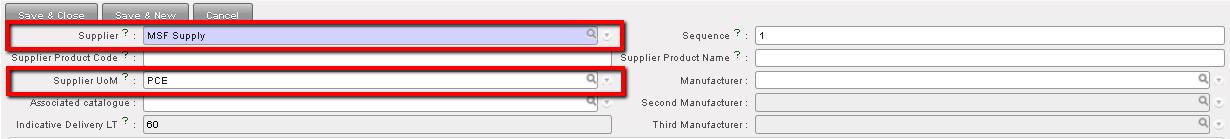

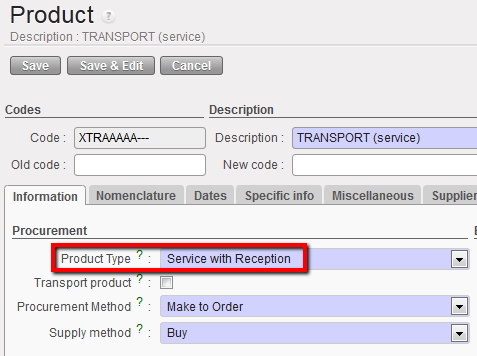

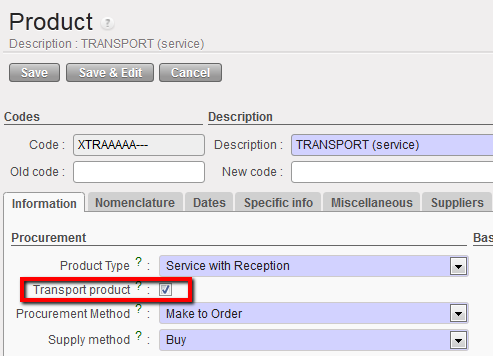

Please note: The UoM in the purchase order service with reception can be percentage (100%) as this will facilitate payment in installments for a service if this was the payment term agreed with the supplier.

Please note: The UoM in the purchase order service with reception can be percentage (100%) as this will facilitate payment in installments for a service if this was the payment term agreed with the supplier.

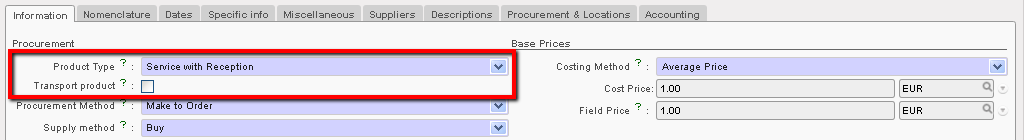

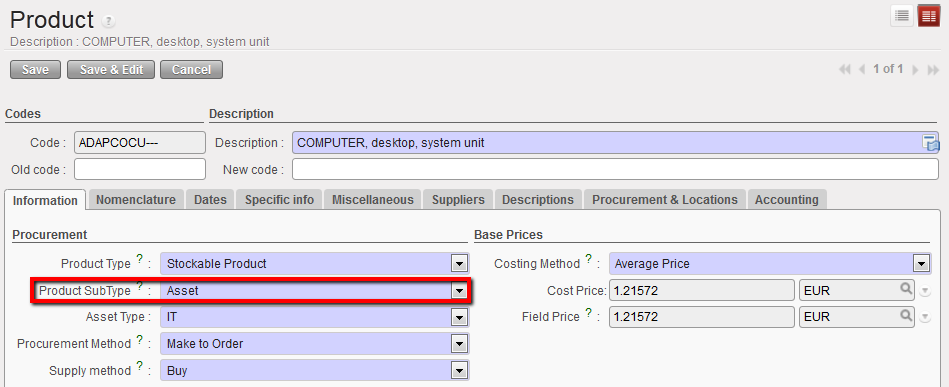

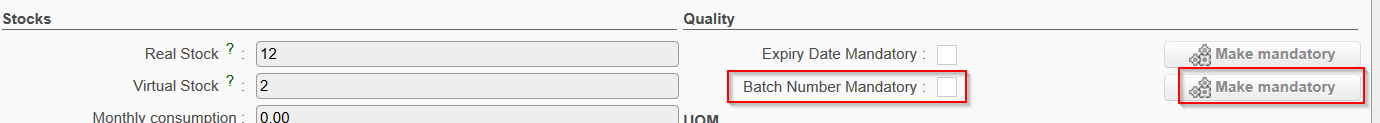

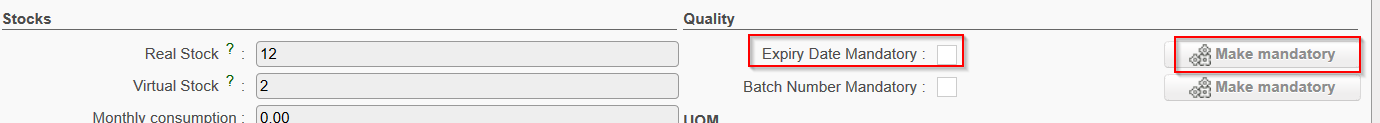

Please note: This attribute needs to be changed cautiously especially if product is in Stock or is in a document in progress.

Please note: This attribute needs to be changed cautiously especially if product is in Stock or is in a document in progress.

Please note: When a product has been successfully de-activated, this means it cannot be viewed or selected from the database when creating transaction documents (e.g. Purchase Orders etc), but can still be seen by searching directly in the “Products” business application. If you wish to see all de-activated products, this can be seen from the Products Action Menu Link “Inactivated Products” or filter button “Inactive” (header right hand)

Please note: When a product has been successfully de-activated, this means it cannot be viewed or selected from the database when creating transaction documents (e.g. Purchase Orders etc), but can still be seen by searching directly in the “Products” business application. If you wish to see all de-activated products, this can be seen from the Products Action Menu Link “Inactivated Products” or filter button “Inactive” (header right hand) De-activated /Inactivated Products link

De-activated /Inactivated Products link

When activating these NSL products, the following warning message is displayed:

When activating these NSL products, the following warning message is displayed: Editing a product form

Editing a product form