Supply User Manual ENG -> 5. Warehouse -> 5.9 LU-SU4202: Claims-> G. TRANSPORT CLAIMS

Transport claims are raised to transport services suppliers when services do not meet the required level of quality.

Supply User Manual ENG -> 5. Warehouse -> 5.9 LU-SU4202: Claims-> G. TRANSPORT CLAIMS

Transport claims are raised to transport services suppliers when services do not meet the required level of quality.

Supply User Manual ENG -> 5. Warehouse -> 5.9 LU-SU4202: Claims-> F. CUSTOMER CLAIMS

Customer claims can be created by the synchronization (see section on claims synchronization below) or manually. Claims will be manually created if the customer is not using UniField or if the customer did not raise a claim using UniField.

Supply User Manual ENG -> 5. Warehouse -> 5.9 LU-SU4202: Claims-> E. HOW TO RETURN CLAIMED PRODUCTS TO SUPPLIER AND REPLACE THEM

If you choose “Return” as claim type, the system will create a Picking Ticket (PICK-return) to send back non conformed goods to the supplier. If you tick the “Replacement expected” checkbox, the system will create an Incoming Shipment (IN-replacement) for the replacement of the goods

The Picking Ticket will be processed to send back the goods to the supplier. Note that you may convert it to an OUT if needed.

The Incoming Shipment will be used to receive goods when the replacement will be sent by the supplier.

Supply User Manual ENG -> 5. Warehouse -> 5.9 LU-SU4202: Claims-> D. HOW TO CREATE A SUPPLIER CLAIM FROM SCRATCH

If goods are noticed non-conformed after their reception in stock (or in cross docking), a claim should be created from scratch.

Go to: Purchases / Claim / Claim

|

| Creating a claim from scratch |

2. Check the “Reference“, “Type” and “Creation Date” fields and update them if needed. The “Type” should be set to “Supplier” if you are raising a claim to a supplier regarding goods non-conformity. “Transport” will be used for services transport suppliers. “Customer” will be used to register a claim raised to you by one of your customers.

3. Select a “Category” related to the non-conformed goods.

4. In the “Reception/Shipment reference” field, select the Incoming Shipment (PICK and OUT will be used for customer claims) reference related to the non-conformed goods. The “Partner” and “Order reference” fields are populated.

5. In the “Order line number” field, enter the order line number related to the damaged goods if you know it.

6. In the “Description” field, explain why you are creating this claim.

|

| Creating a claim from scratch |

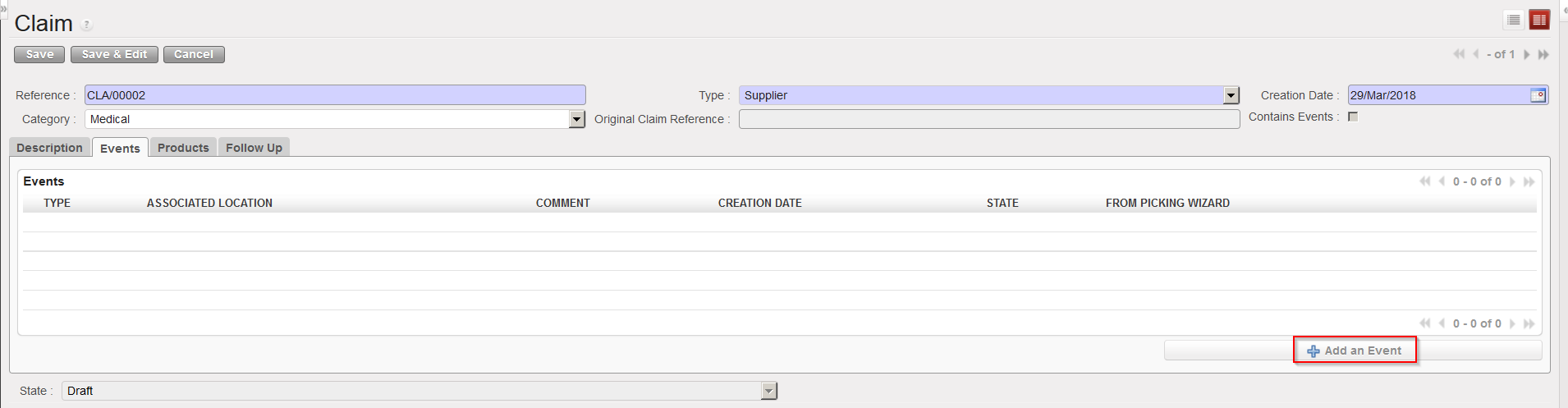

7. On the “Events” tab, click on the “Add an Event” button.

|

| Adding an event to a claim |

8. Complete the “Add an Event” screen. For the Event type, choose from the options:

|

| Adding an event to a claim |

9. Tick the checkbox “Replacement expected” if you wish the goods to be replaced.

10. Click on the “OK” button.

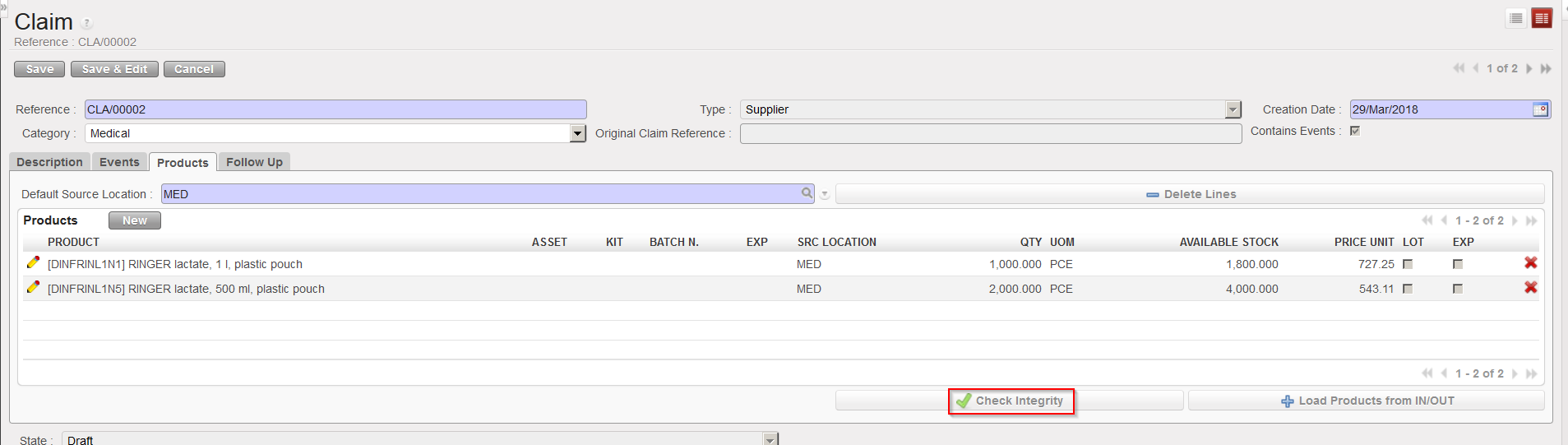

11. On the “Products” tab, update the “Default Source Location” if needed. This is the location where the products for which you are raising a claim are currently stored.

12. On the “Products” tab, add products by:

|

| Adding products on a claim |

13. Check/update/enter the quantities and any other relevant information such as Asset reference, BN/ED, unit price,…

14. Ensure that the “SRC LOCATION” indicates where these products currently are.

15. Click on the “Check Integrity” button to check that these products are available in the source location.

|

| Checking the integrity of the entered products |

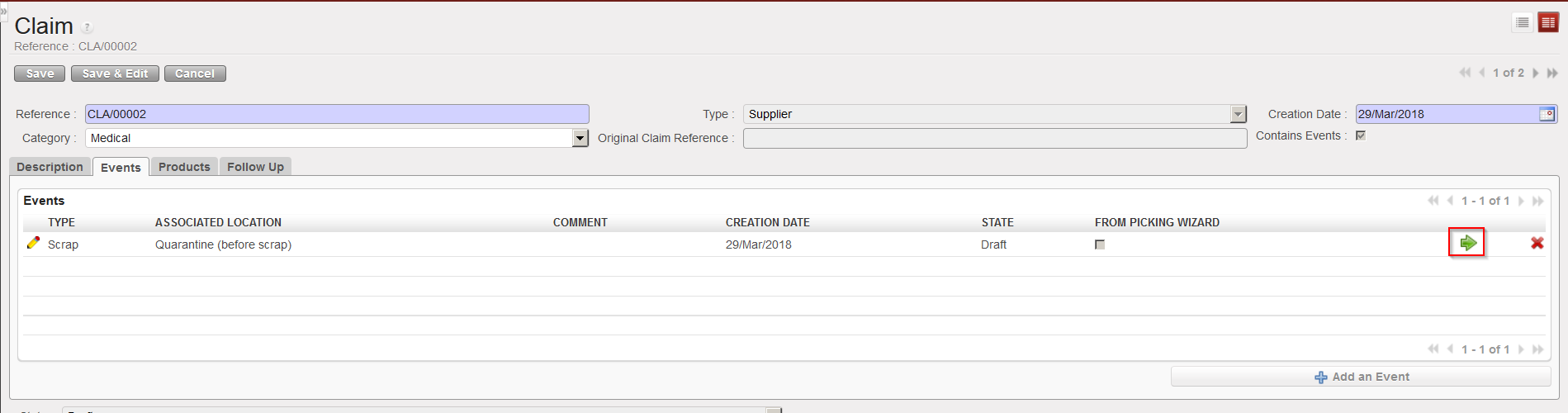

16. Select the “Events” tab.

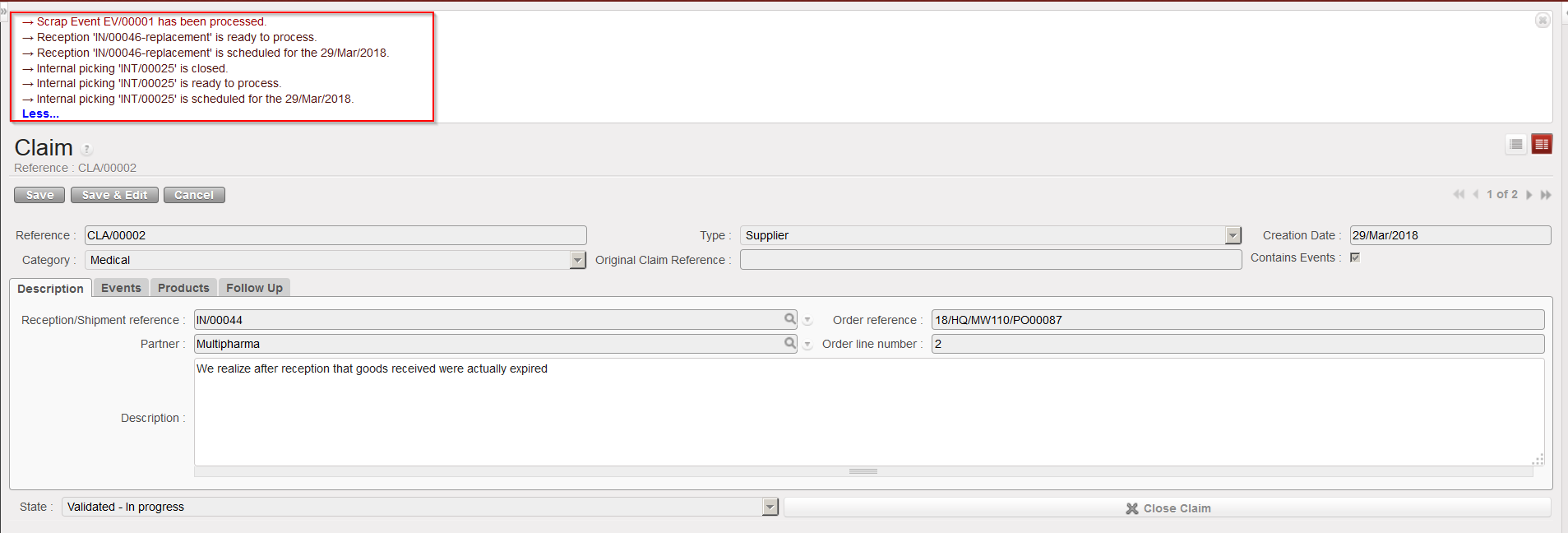

17. Click on the green arrow to process the claim event. A message will appear confirming (according to the event selected) that an internal picking (INT) has been created, processed and closed (if you selected “Scrap” as event type), that a reception IN-replacement is ready to process (if the replacement expected checkbox was ticked) and that the event has been processed.

|

| Processing the claim event |

|

| Claim event processed |

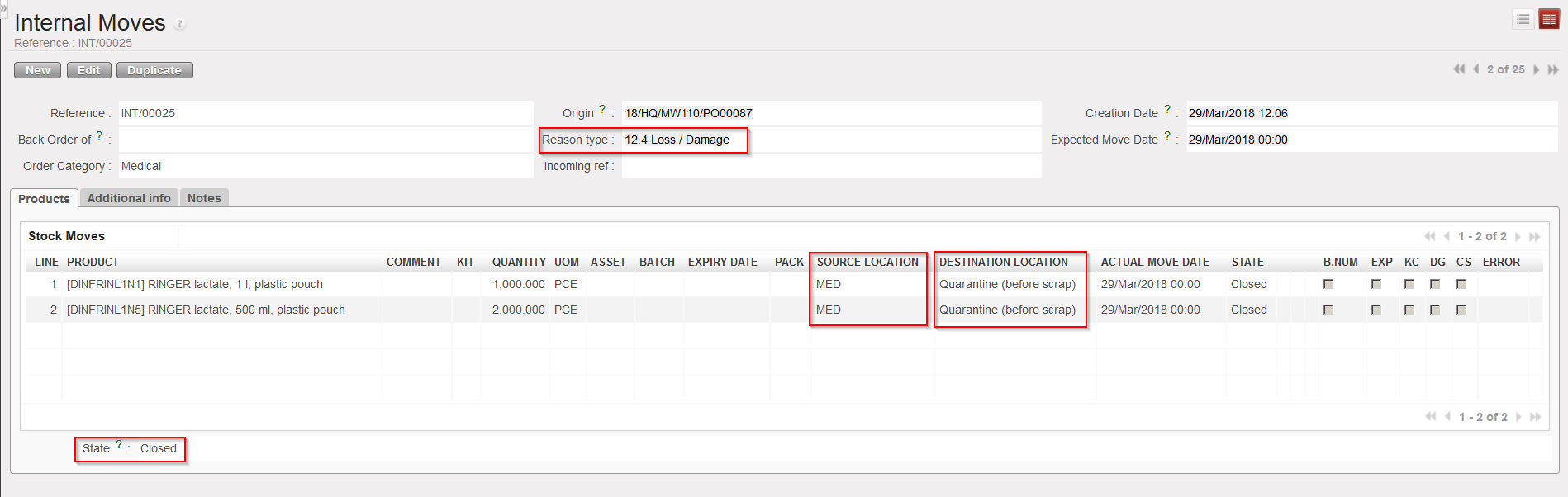

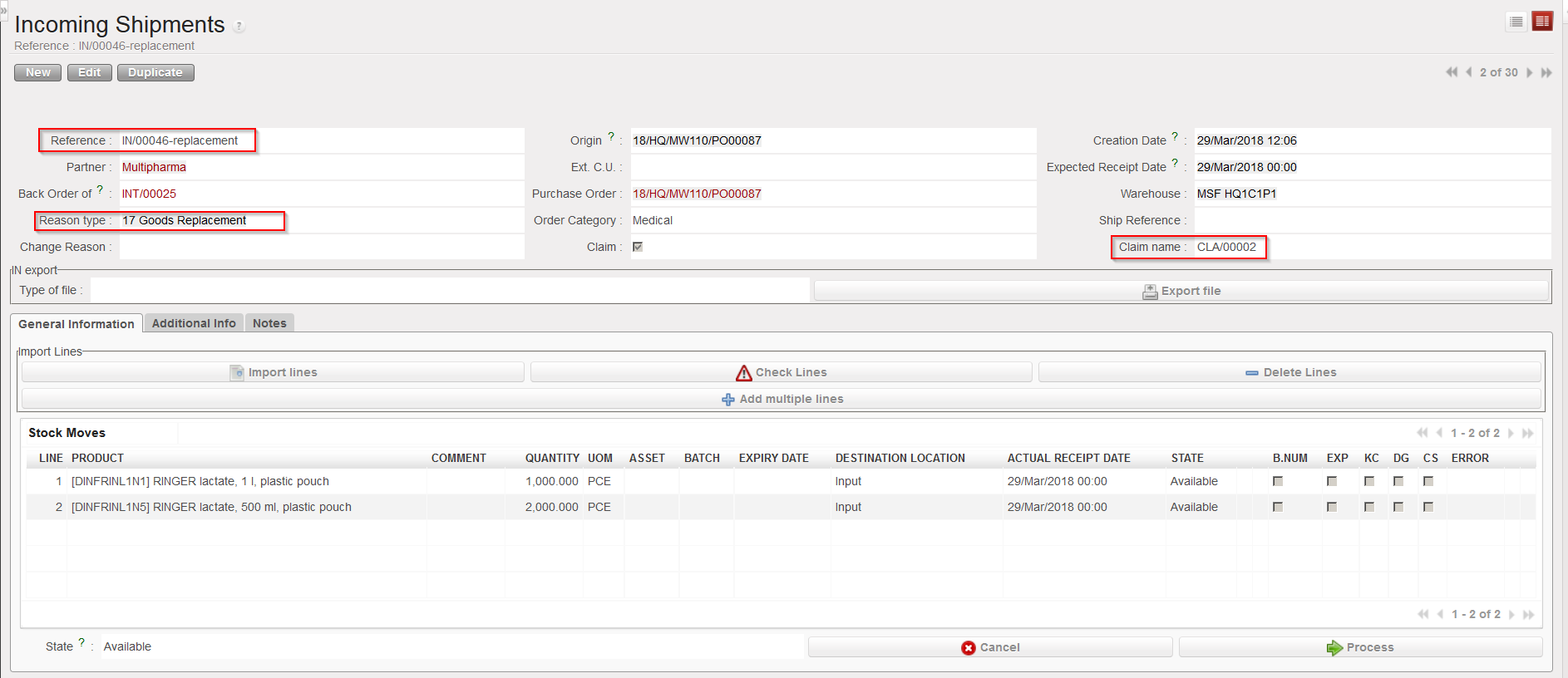

With the above selected options (claim type = Scrap and replacement of goods requested), the system:

|

| INT created by the claim |

|

| IN-replacement created by claim |

|

| Supplier master data sheet updated by claim |

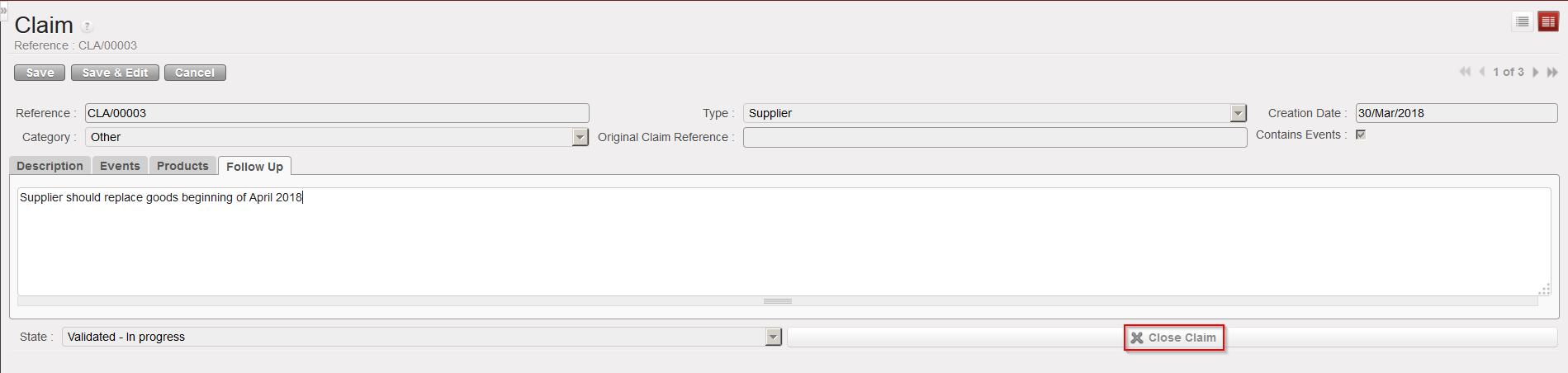

18. Click on the follow up tab. You may add here any additional information related to claim follow-up.

19. When the claim has been closed (e.g. goods have been replaced and all is clear on the invoicing side) you can close the claim by clicking on the “Close Claim” button.

|

| Closing a claim |

Supply User Manual ENG -> 5. Warehouse -> 5.9 LU-SU4202: Claims-> C. HOW TO CREATE A CLAIM FROM AN INTERNAL MOVE (after reception in the "Input" location).

As the “Input” location is used to perform qualitative checks following suppliers deliveries, claims should actually be raised when products transit through this location. This will only happen if the “Direct to Requesting Location” checkbox is unticked during goods reception.

Go to: Warehouse / Warehouse Management / Internal Moves

|

|

|

Processing the Internal Move |

|

|

|

Transferring the conformed goods to their final destination |

|

|

|

Initial INT with non conformed goods in back-order |

|

|

|

New INT with conformed goods in state “Closed“ |

4. On the initial INT, click again on the “Process” button.

5. On the “Products to Process” screen, click on the “Copy all” button if all remaining product lines and quantities should be included in a claim. Otherwise, use the pencil icons and select products/quantities you want to make a claim for.

6. Tick the checkbox “Register a Claim to Supplier“.

|

|

|

Processing the non conformed goods |

7. If empty, enter the supplier.

8. As Claim Type, select from the drop down list one of the following options:

9. Tick the “Replacement expected for Claim” checkbox if you have already agreed with the supplier that the products will be replaced.

10. Use the “Claim Description” tab if you want to enter a description for the claim.

|

|

|

Requesting replacement for non conformed goods |

Note that if you want to create different claim types for a same INT (e.g. if you want to return some goods but scrap others) you will have to process the above transaction in several steps (i.e. repeat it).

11. Click on the “Process” button.

|

|

|

INT cancelled |

With the above selected options (claim type = Return and replacement of goods requested), the system:

|

|

|

Claim created |

|

|

|

PICK-return created |

|

|

|

IN-replacement created |

|

|

|

Supplier master data sheet updated |

Supply User Manual ENG -> 5. Warehouse -> 5.9 LU-SU4202: Claims-> B.HOW TO CREATE A CLAIM FROM AN INCOMING SHIPMENT

It may happen that you realize that goods delivered by a supplier dot not conform with the confirmed order before any reception is done. In this case you may raise the claim from the IN.

Go to: Warehouse / Warehouse Management / Incoming Shipments

|

|

|

Processing the non conformed goods |

7. If empty, enter the “Supplier“.

8. As “Claim Type“, select from the drop down list one of the following options:

9. Tick the “Replacement expected for Claim” checkbox if you have already agreed with the supplier that the products will be replaced.( note that this will consequently split the related line in the related PO)

10. Use the “Claim Description” tab if you want to enter a description for the claim.

|

|

|

Requesting replacement for non conformed goods |

Note that if you want to create different claim types for a same IN (e.g. if you want to return some goods but scrap others) you will have to process the above transaction in several steps (i.e. repeat it).

11. Click on the “Process” button.

|

|

|

INT cancelled |

With the above selected options (claim type = Accept and replacement of goods requested), the system:

|

|

|

Closed IN |

|

|

|

Claim created |

|

|

|

IN-replacement created |

|

|

|

Supplier master data sheet updated |

Supply User Manual ENG -> 5. Warehouse -> 5.9 LU-SU4202: Claims-> A. LU INTRODUCTION (LU-SU4202)

Quantitative and qualitative analysis of products may happen at different times. In most cases, the products will be counted and nominally checked at the point of reception, and if they do not correspond to the confirmed order at this point, the supplier should be contacted and a claim should be raised.

Claims raised during reception, can be created at two steps: from the Incoming Shipment or from an Internal Move.

An exception to this is the situation where the goods have been delivered directly into the “Cross docking” location or into Stock if the “Direct to Requesting Location” checkbox was left ticked when processing the IN. In these cases the claim should be raised from scratch.

Another situation is the one in which goods have been in stock for a certain period after reception. If there is an issue with these goods and if you realize that this is due to the supplier, a claim from scratch can also be created at this point.

In some cases, you may need to create a claim for the supplier of the transport, for example because the goods were damaged as a result of transportation and this would be a claim type transport.

Creating a claim will allow us to record what is wrong with the delivery received, and what we have decided to do with the products (e.g. return them to supplier, destroy them,…). It may be necessary to contact the supplier before creating the claim. Any claim created will also be recorded in the Supplier’s record. If the products are sent back to the supplier (via a return event being created within the claim), this will impact the final invoice to pay to the supplier to ensure that we do not pay for goods which we have not kept.

Note that if a claim is created by a UniField instance and addressed to another (supplier) UniField instance, the synchronization will create a customer claim on the supplier instance.

Supply User Manual ENG -> 5. Warehouse -> 5.9 LU-SU4202: Claims.

B. HOW TO CREATE A CLAIM FROM AN INCOMING SHIPMENT

C. HOW TO CREATE A CLAIM FROM AN INTERNAL MOVE (after reception in the “Input” location)

D. HOW TO CREATE A SUPPLIER CLAIM FROM SCRATCH

E. HOW TO RETURN CLAIMED PRODUCTS TO SUPPLIER AND REPLACE THEM

Supply User Manual ENG -> 5. Warehouse -> 5.8 LU-SU4201: Internal Moves -> G. INTERNAL MOVES REFERENCES

If you look at the INT screens, you will find various types of references (document numbers):

a) for movement from the “Input” location to the final destination of the goods. These INT will be automatically/manually processed if the “Direct to Requesting Location” checkbox is ticked/not ticked.

b) for Internal Move created from scratch

2. INT/KITXXXXX. This type of reference is used in case of kit substitution or de-kitting (see the section on kits for details)

3. SYS-INT/XXXXX. This type of reference is used for these very special Internal Moves which have been introduced in the previous section

Supply User Manual ENG -> 5. Warehouse -> 5.8 LU-SU4201: Internal Moves -> F. SYSTEM INTERNAL MOVES

Explanations in this section are quite technical. Skip them if you do not want to enter into this. The section on virtual stock in LU-SU4302 may help to understand them as these SYS-INTs are used to impact the virtual stock levels. More specifically they are used in order to insure that Replenishment Rules can work. See specific section on RR as well.

In any case, bear in mind that you should not touch these Internal Moves. SYS-INTs should always be created, confirmed updated and cancelled by the system, never touched by a user.

These special Internal Moves are created by the system when a PO (or PO-line) with “Input” as planned destination location is confirmed. This confirmation triggers the creation of an Incoming Shipment with “Input” as destination location.

This means that SYS-INT are created in 2 cases:

The lines of the created IN (which is in state “Available” with all its lines “Available”) have “Input” as destination location. This means that the virtual stock level of the “Input” location will be directly impacted by this IN.

However, the virtual stock level of the final destination location (stock or ICU) is not impacted by the IN.

The SYS-INT (created in the state “Confirmed” with its lines “Not available”) is actually simulating a movement between the “Input” location and the final destination location. It decreases the virtual stock level of the “Input” location (which is increased by the IN) and increases the virtual stock level of the final destination location.

With this feature, users are able to have a better view on where the virtual stock levels will be. They can see “further” than the “Input” location.

The processing of the IN will update (in case of partial reception) or cancel the SYS-INT according to the situations. In addition, this will also create the Internal Move as usual, to move goods (manually or automatically) from the “Input” location to the final destination location.