Manuel de l’Utilisateur Supply -> Général Supply

J. a) Order follow up

Supply User Manual ENG -> 4. Procurement -> 4.2 LU-SU3101: Internal Requests (IRs) -> J. a) Order follow up

J. a) Order follow up

- Click on the check box on the left side of the line corresponding to the Internal Request to be followed-up.

- The action menu on the right-hand side is displayed.

- Click on the “Order Follow Up” option.

|

|

|

Following-Up an Internal Request |

4. A detailed Order Follow Up is displayed.

5. The “Update” button can be used to refresh the page.

6. The report can be exported in Excel or PDF via the corresponding buttons.

|

|

|

Export IR follow up to XLS or PDF format |

- Users can search for IRs in the main List view for Internal requests by using filters: Order Reference, Origin, Requestor and Location Requestor.

H. How to cancel or delete a whole Internal Request.

Supply User Manual ENG -> 4. Procurement -> 4.2 LU-SU3101: Internal Requests (IRs) -> H. How to cancel or delete a whole Internal Request.

H. How to cancel or delete a whole Internal Request.

Internal Requests can be cancelled by clicking on the “Cancel document” button (with the red cross) in the lower part of the order.

Note that the “Cancel” button (only available in edit mode) at the top of the screen (without the red cross) will only cancel the changes you made in the document since the last time you saved it.

An IR can be cancelled if it is in either “Draft“, “Draft-p“, “Validated” or “Validated-p” state. After this, the IR can only be cancelled at another following stage (e.g. at PO stage). Please note that if Cancellation is done at OUT or PICK stage after IR has been sourced to a PO then the IR will be “Closed” whereas it will be “Cancelled” if the sourcing is done “from Stock”.

When an IR is cancelled, its status turns to “Cancelled” and all its lines also take the status “Cancelled“. Note that by default, cancelled IR lines are not showed. If you want to see them, use the filter drop-down box available at the top of the products table. This filter allows to hide cancelled lines, show all lines or show cancelled lines only.

|

| IR cancellation |

|

| IR cancelled |

|

| Filtering lines appearing on an IR |

An Internal Request can also be deleted. This can only be done if the IR is in the state “Draft” (at header level). Use the red cross located on the IR you want to delete on the “Search: Internal Requests” screen to delete a “Draft” IR.

|

| Deleting a “Draft” IR |

G. How to update an Internal Request.

Supply User Manual ENG -> 4. Procurement -> 4.2 LU-SU3101: Internal Requests (IRs) -> G. How to update an Internal Request.

G. How to update an Internal Request.

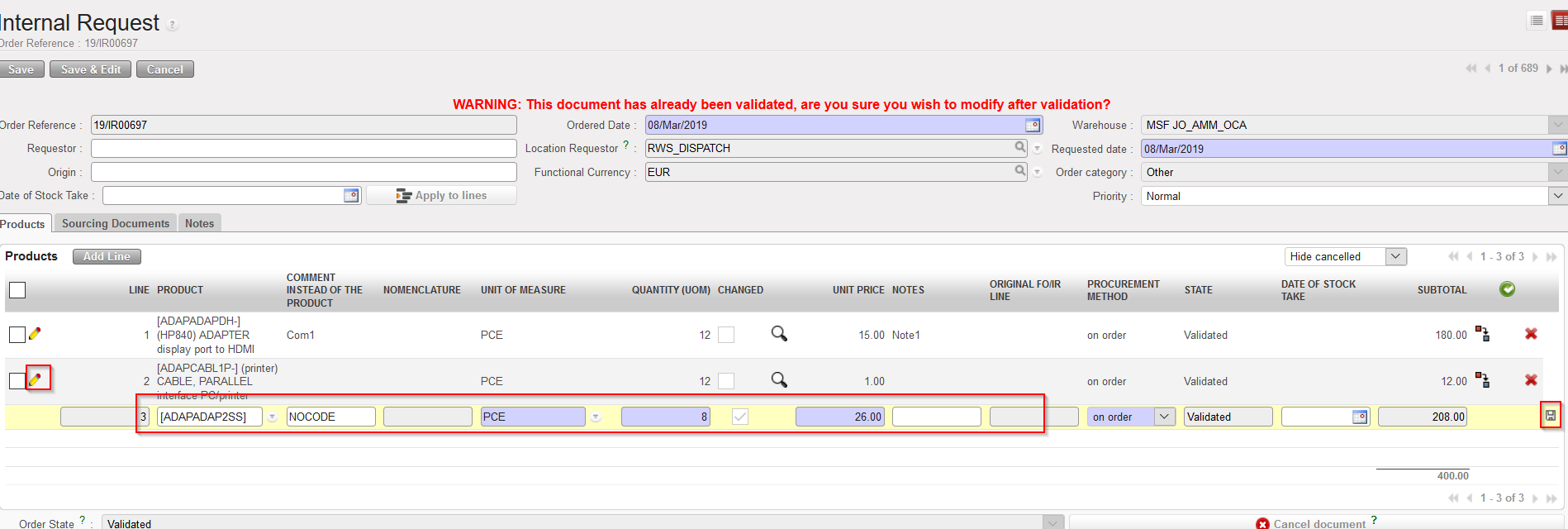

Internal Request updates can be done manually in the IR in “Draft” , “Draft-p“, “Validated” or “Validated-p” status.

Go to: Orders / Orders / Internal Requests

- Enter the necessary information in the filters to find your IR and click on Search, then click on the pencil icon

next to the IR you wish to update to open it in edit mode.

next to the IR you wish to update to open it in edit mode. - Update some information on the header of the IR if needed (some header fields can only be updated when in Draft/Draft-p).

- To update a specific line, click on the pencil icon

at the left of the line you wish to update.

at the left of the line you wish to update. - Update the line as needed (UoM, quantity, unit price, notes,…).

- Save the line by clicking on the floppy disk

at the right of the line or via a click on “Enter“.

at the right of the line or via a click on “Enter“.

|

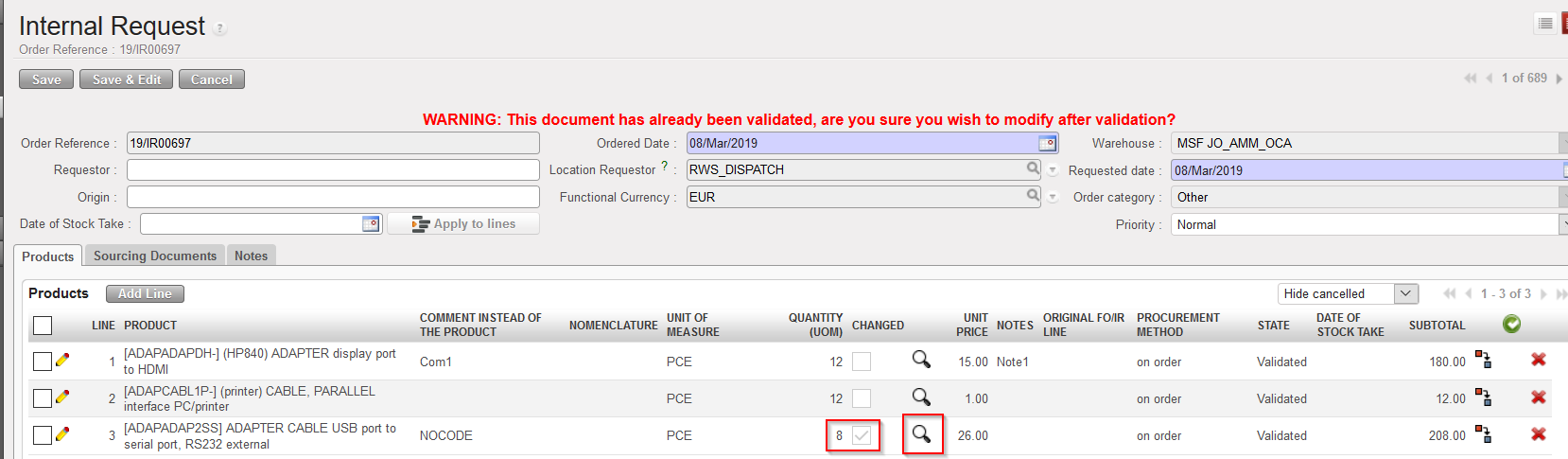

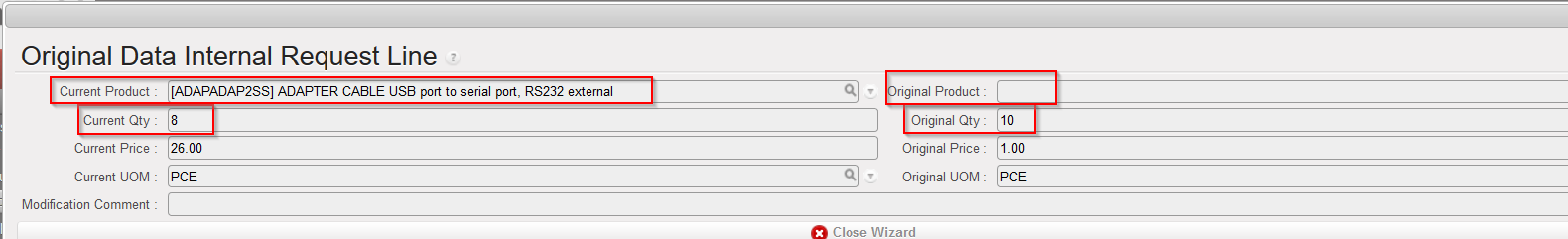

Please note that any change on “Product”, “Quantity”, “Price” and “UoM” to a “Validated” line will trigger the ticking of the “Changed” checkbox. Changes can be seen by clicking on the “Magnifier” icon; once clicked , a pop up will display the changes on the specific product line with “current value” vs “original value”.

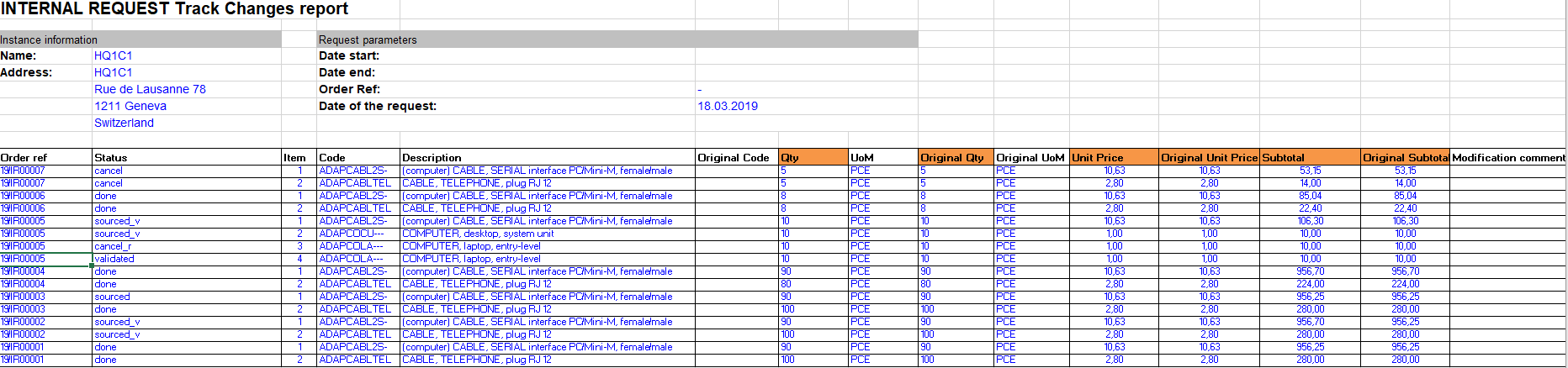

Please note that there is as well a new report that enables to see all these “track changes” which can be find under “Order> Orders” IR Track Changes”

As long as the IR is in “Validated” status, it is still possible to add new line to the order however this will trigger the “Changed” checkbox.

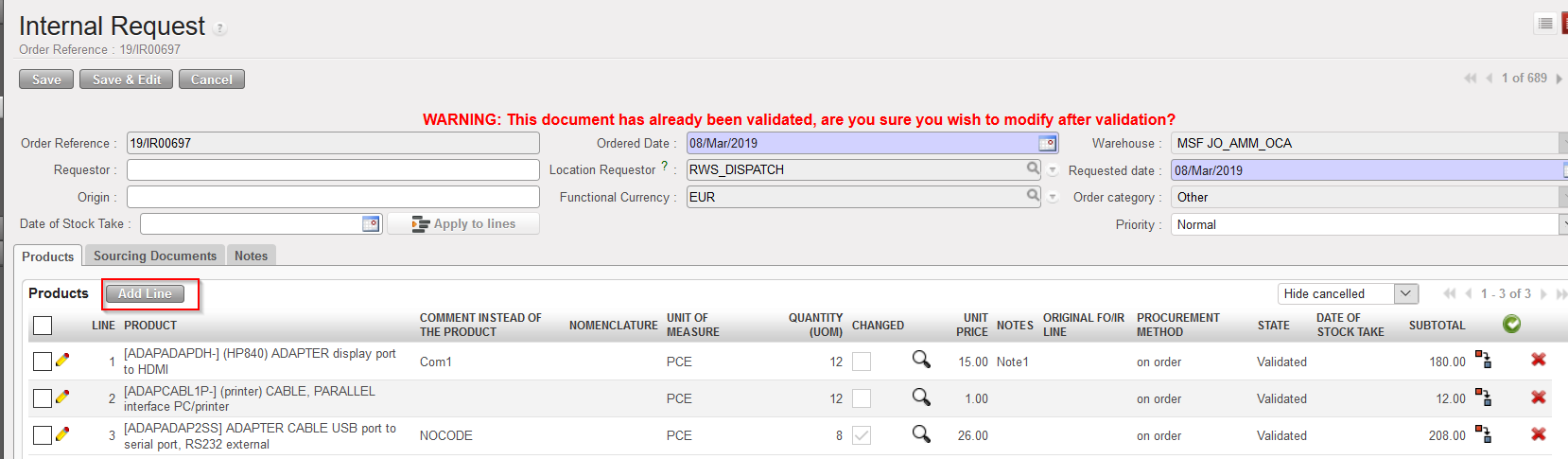

The addition of new lines to a “Validated” IR is conditioned by User rights. A new button named “Add line” will replace the “New” button which is only used for Draft IR. New lines added at “Validated” state will still be created as “Draft” and will need validation from authorized user.

F. b) How to validate an Internal Request at line level.

Supply User Manual ENG -> 4. Procurement -> 4.2 LU-SU3101: Internal Requests (IRs) -> F. b) How to validate an Internal Request at line level.

F. b) How to validate an Internal Request at line level.

- Search for and open (in edit or display mode) the IR you wish to validate.

- You may then

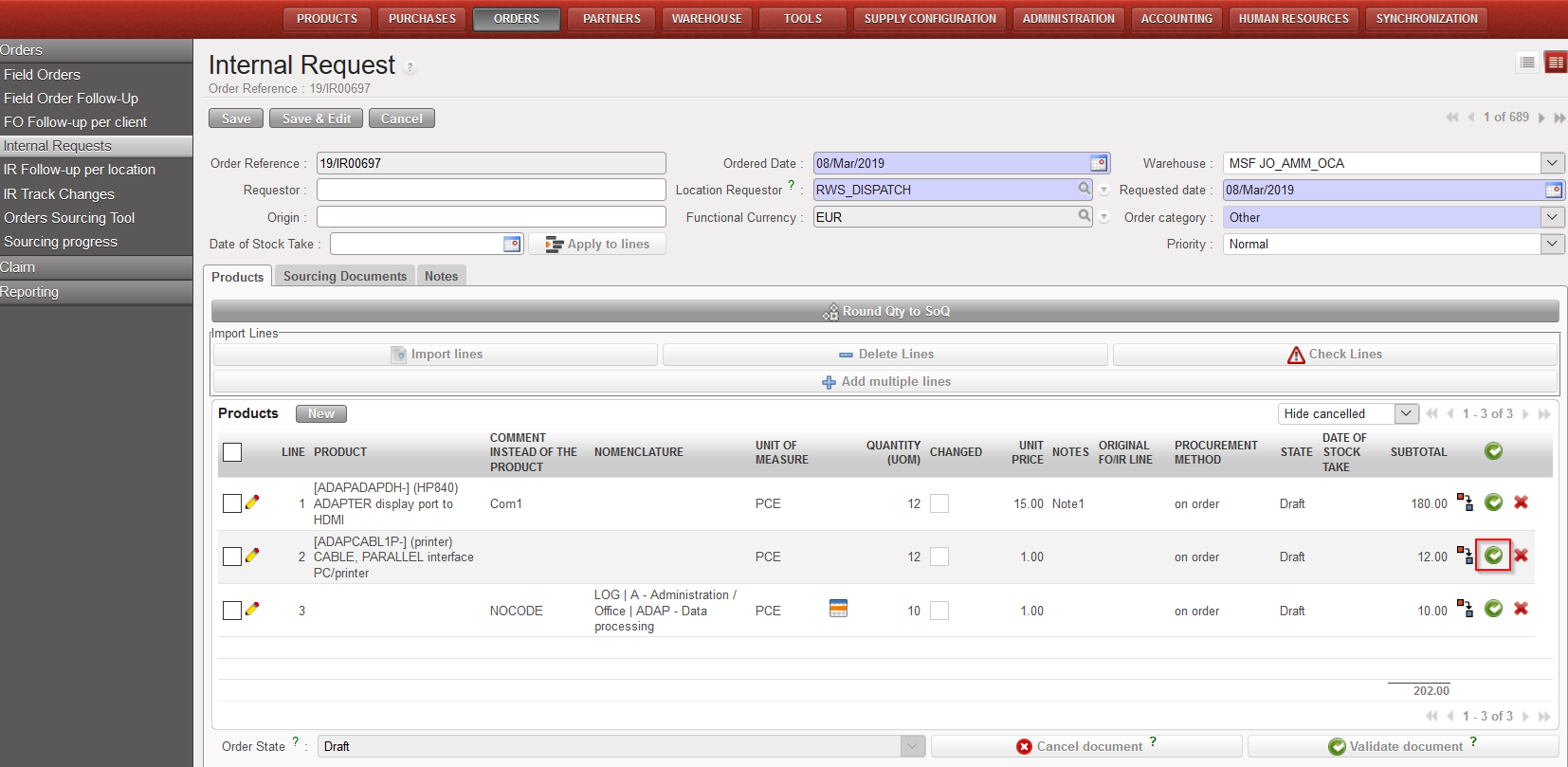

1.1 Validate only 1 line of the IR by clicking on the green icon at the right of the line you want to validate.

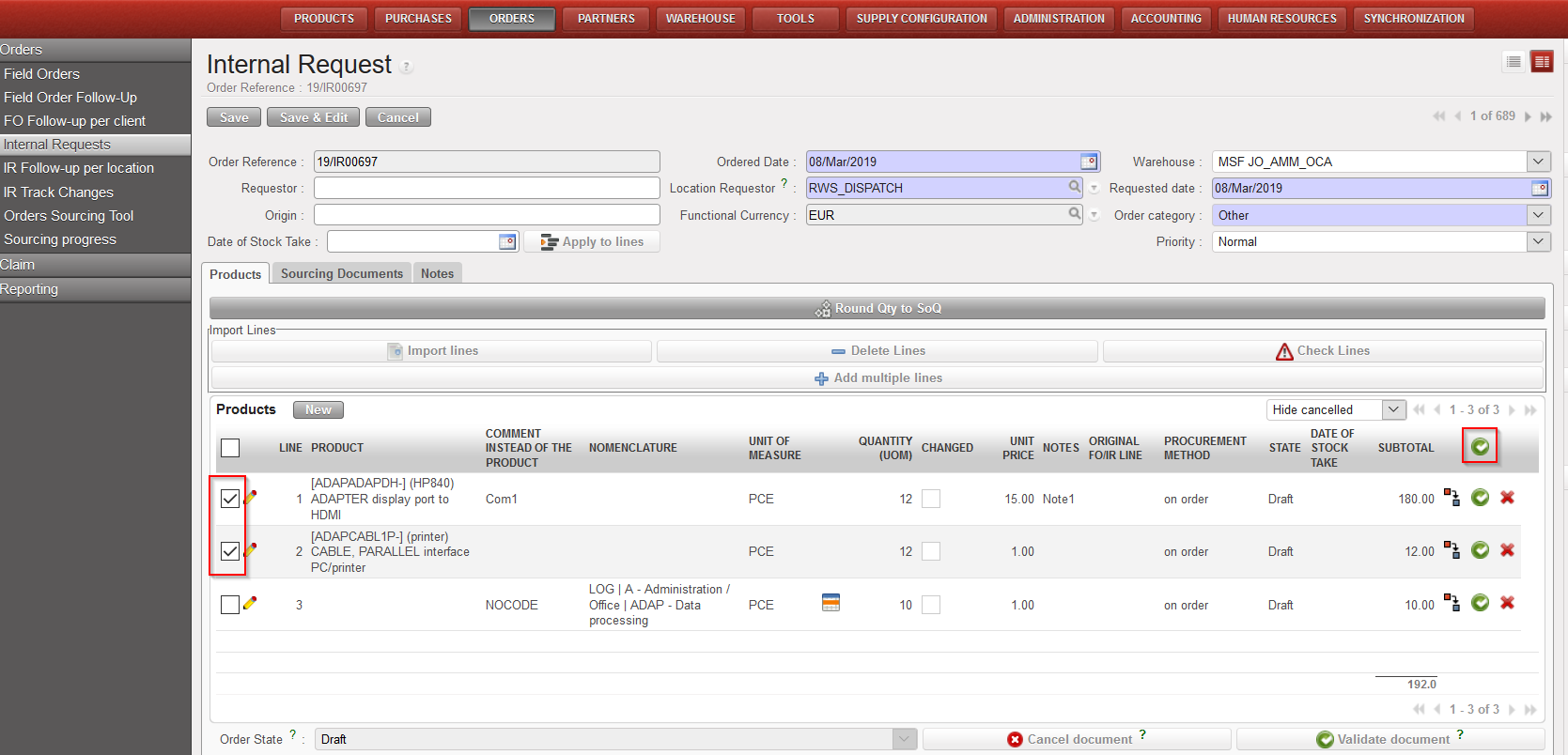

1.2 Validate several lines of the IR by selecting the lines you want to validate (use the check boxes on the left of the lines) and validating the selected lines (use the green icon at the top of the products table, next to “SUBTOTAL”).

|

| Validate 1 line on an IR |

|

| Validate several lines on an IR |

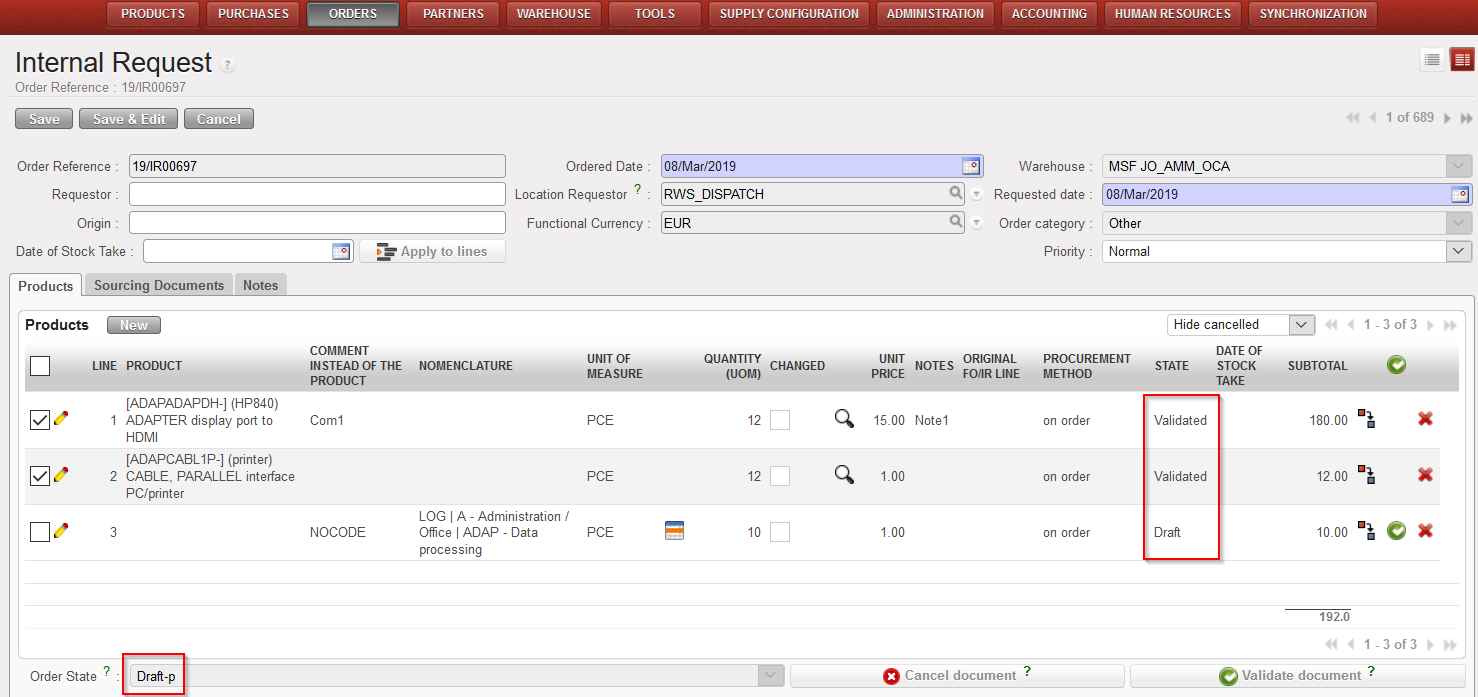

Once Validated:

-The validated line(s) of the IR switch to the state “Validated” (while the other lines stay in the state “Draft”).

-The IR switches to the state “Draft-p“.

-No warning message is displayed as the lines of the IR which remain in the state “Draft” can still be modified.

|

| IR partially validated |

Remember that to be able to validate partially an Internal Requests, your user must have the appropriate user rights.

F. a) How to validate an Internal Request at header level.

Supply User Manual ENG -> 4. Procurement -> 4.2 LU-SU3101: Internal Requests (IRs) ->F. a) How to validate an Internal Request at header level.

F. a) How to validate an Internal Request at header level.

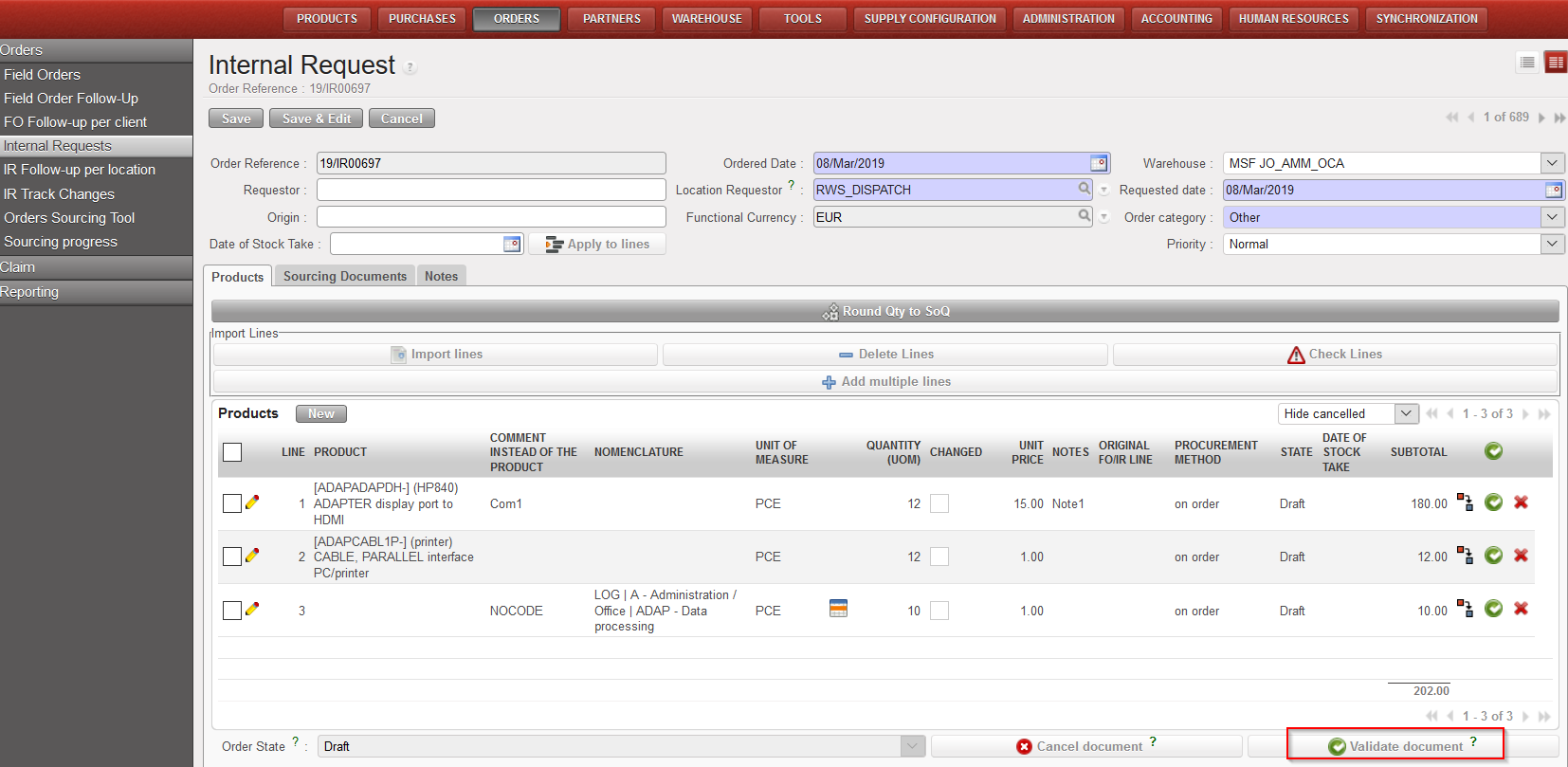

- Search for and open (in edit or display mode) the IR you wish to validate.

- Click on the “Validate Document” button at the bottom of the screen.

|

| IR validation |

Once Validated:

-All the lines of the IR switch to the state “Validated“.

-The IR switches to the state “Validated“.

-A red non-blocking warning message is displayed to remind that changes are not recommended after validation.

|

| IR validated |

F. How to validate an Internal Request.

Supply User Manual ENG -> 4. Procurement -> 4.2 LU-SU3101: Internal Requests (IRs) -> F. How to validate an Internal Request.

F. How to validate an Internal Request.

An Internal request can be validated at header level (validation done for all the lines of the IR in one click) or at line level (validation done for one or some lines of the IR only).

In the first case, the validation will have as consequence that all the lines of the IR will switch to the state “Validated” and the IR itself (at header level) will also switch to the state “Validated“. In the second case, the validation will have as consequence that one or some lines of the IR will switch to the state “Validated” while the IR itself (at header level) will switch to the state “Draft-p“.

Note that to be able to validate an IR at line level, a user must be granted specific user rights. User should have the group Sup_Valid_Line_IR.

Go to: Orders / Orders / Internal Requests

D. How to import lines on an Internal Request.

Supply User Manual ENG -> 4. Procurement -> 4.2 LU-SU3101: Internal Requests (IRs) -> D. How to import lines on an Internal Request.

D. How to import lines on an Internal Request.

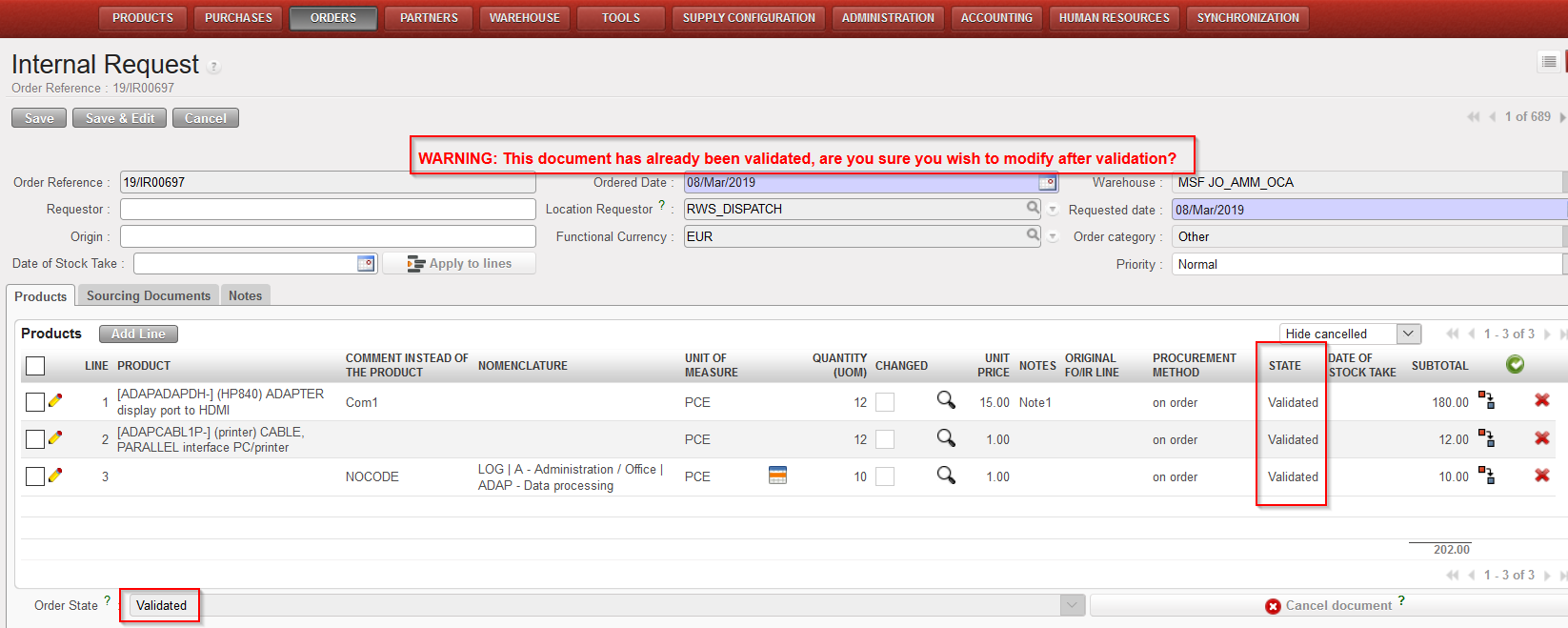

UniField offers several options for importing information on an IR, either from an Excel file (XML Spreadsheet 2003 format) or from a pre-encoded Product list.

First and historical option only include import of product lines information and requires having header information of IR to be populated manually in the system. The columns should be in this exact following order and spelling: Product Code*[1], Product Description, Quantity*, Cost Price, UoM*, Currency*, Comment.

|

| IR Excel Import format and columns order |

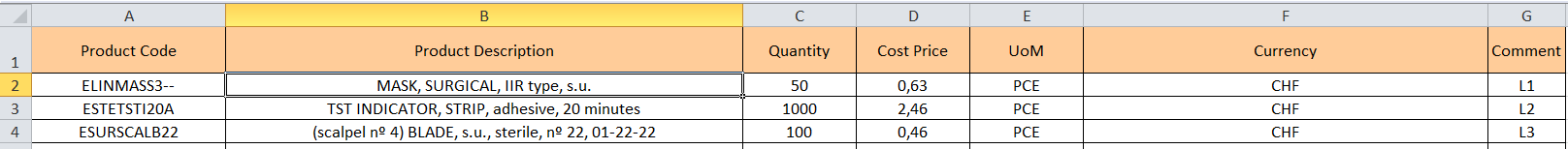

Option 1 (import lines): Go to: Orders / Orders / Internal Requests

- Create a new IR or open an existing IR (note that for an existing IR, this should only be done if the IR is in “Draft” or “Draft-p” status and saved first).

- Click on the “Import lines” button.

- Click on the “Add attachment” button then “Browse” and search on the computer for the file to import.

- Select the file you want to upload and click on “Open” in the browse window.

- Click on the “Import file” button to import the file, then click “Update” (Click again on “Update” if the process is not 100% complete). A message will indicate if lines have been imported successfully.

- Click on the “Close Window” button.

- Save the IR.

|

| Importing lines on an IR |

The second option introduced with UF11 enables to import, additionally to product line, header information such as Order reference (in case of update), Order Category, Priority, Requested date*, Requestor, Location requestor*, Origin and Functional currency.

This import can only be done to create Draft IR or update existing Draft IR.

Option 2 (Import from IR Excel template): Go to: Orders / Orders / Internal Requests

- Click on the “Import from IR Excel template” link on the right action menu.

- Click on the “Add attachment” button then “Browse” and search on the computer for the file to import.

- Select the file you want to upload and click on “Open” in the browse window.

- Click on the “Import file” button to import the file, then click “Update” (Click again on “Update” if the process is not 100% complete). A message will indicate if lines have been imported successfully. Please note that if mandatory fields are not filled or incorrect, a non-blocking message will inform about it and correction can still be made on screen.

- Click on the “Validate Import” button.

- Save the IR.

Note that comments can also be imported in the IR if you populate the “Comment” column of the Excel.

Note that “product by nomenclature” lines can also be imported from Excel into an IR. Leave the “Product Code” (and “Product Description“) columns empty and populate the “Comment” column. Afterwards, use the “Configurator” icon to complete the line.

From the “Import from IR Excel template” import pop up, you can check the box “Change Product to a Comment if Product is not found” in case you need to import product by nomenclature.

To get a template of the correct Excel format needed, you may export an existing IR to Excel as explained below (see How to export lines from an Internal Request).

Option 3 (import from product list): Go to: Orders / Orders / Internal Requests

- Create a new IR or open an existing IR (note that for an existing IR, this should only be done if the IR is in “Draft” status). The header information of IR must be filled and saved.

- Open an action menu and select on “Import Product List IR Excel”.

- Click on the “Add attachment” button then “Browse” and search on the computer for the file to import.

- Select the file you want to upload and click on “Open” in the browse window.

- Click on the “Import file” button to import the file, then click “Update” (Click again on “Update” if the process is not 100% complete). A message will indicate if lines have been imported successfully. Please note that lines will be imported only if quantity is >0.

- Click on the “Close Import” button.

- Save the IR.

- *Indicates a mandatory field in the XML file. ↑

A. LU Introduction (LU-SU3101).

Supply User Manual ENG -> 4. Procurement -> 4.2 LU-SU3101: Internal Requests (IRs) -> A. LU Introduction (LU-SU3101)

A. LU Introduction (LU-SU3101).

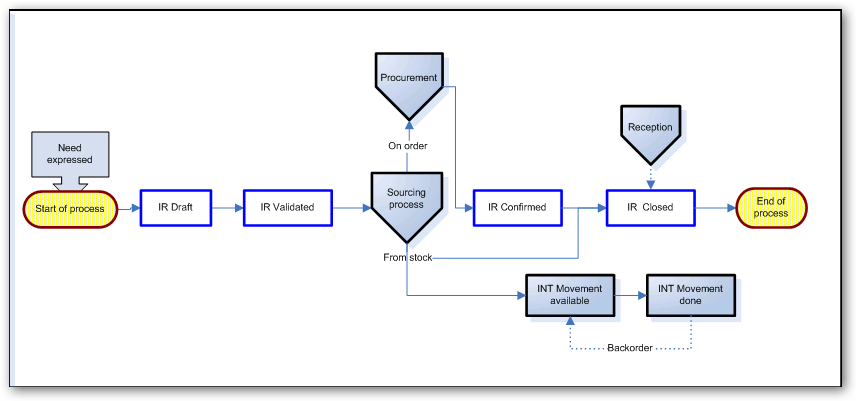

An Internal Request (IR) is a document used to express a requestor’s needs. It is the electronic equivalent of the paper Request Form and replaces the LogistiX “Document IN”. It should be used according to OC procedures.

The needs can come from a user at project or coordination level, it will trigger most procurement documents (if needed) to deliver the goods to the instance where the IR has been created and to the destination location indicated on the IR. The IR has to be reviewed and validated before going through the sourcing tool (and being confirmed).

Process flow of an Internal Request (internal requester)

4.1 CHAPTER OVERVIEW: ORDERS, PURCHASES AND REPORTING.

Supply User Manual ENG -> 4. Procurement -> 4.1 Orders, Purchases and Reporting.

Orders, Purchases and Reporting.

This chapter covers the different types of orders available in UniField, as well as each different stage of sourcing and procurement. The process will start as an expression of needs, and this may be followed by procurement, sourcing from stock, loan, which may involve both internal (via synchronization) and external partners.

It is essential to understand how product orders and procurement are processed in UniField, as an order line may pass through several different stages until the product reaches its final destination. All these stages, up to the point of product reception, are covered in depth in this chapter.

This chapter also covers the relationship between projects and coordination and the role which the synchronization can play in the order flows between them.

This chapter is introducing gradually the different functionalities of UniField needed in procurement, starting with Internal Requests, continuing with the Orders Sourcing Tool before to focus on Field Orders and Purchase Orders. As these functionalities are highly interconnected within UniField, it was not possible to keep them completely separated; reason why some functionalities such as Field Orders and Purchase Orders are already introduced before their dedicated learning units.

As of UF7.0 (released in January 2018), documents used in procurement (Internal Requests -IR-, Field Orders -FO- and Purchase Orders -PO-) can be processed at header level (for the whole document) or at line level (for specific items in the document). This is a major change that has been introduced in UniField to allow -among others- partial sourcing and partial confirmation of orders.

Throughout this chapter, you will find many acronyms. They are mostly used to shorten English words but can be used in the English manual or the French manual (i.e. you may find the acronym PO in the French version of the manual). In the below table, you find the main acronyms used in this chapter with their meaning.

French acronyms, such as the names of the documents in French in a less extend, are barely used. English acronyms and documents names are usually preferred. In the software, references of documents are often built with the English acronyms of the documents (e.g. 18/IR00019, 18/HQ/MW101/FO00033, 18/HQ/MW101/PO00045…), independently of the language in which the software is used.

The language in which UniField is developed is English. The software is then translated in French. That’s the reason why, even if you are connected in French, you could still find some English terminology (on screens, in messages,) while working on UniField. The translation of the software in French is a work in process and some improvements are still needed on this side.